-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 11:31

Back to list

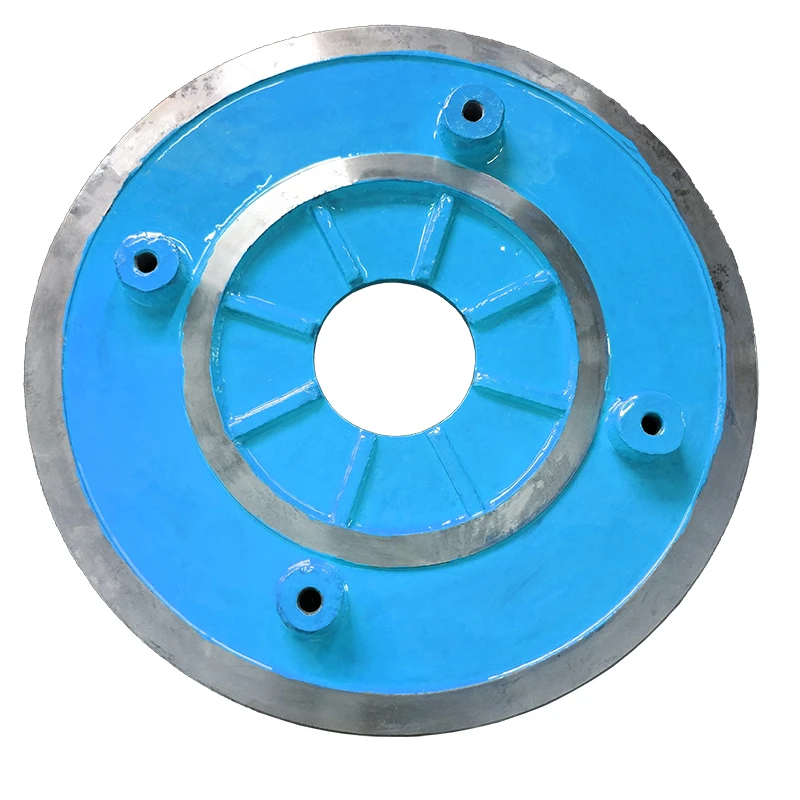

vertical pump bearings

Vertical pump bearings are critical components that ensure the efficient and smooth operation of vertical pumps, widely utilized in industries such as water treatment, oil and gas, chemical processing, and power generation. These bearings support the rotational movement of the pump shaft while mitigating friction and balancing radial and axial loads. Understanding their role, functionality, and maintenance is essential for optimizing pump performance and extending the equipment's lifespan.

Upgrading to advanced bearing technologies can yield substantial performance improvements and cost savings. Innovations such as magnetic bearings eliminate physical contact, reducing friction and wear to nearly zero. These bearings are gaining popularity for their high efficiency, low energy consumption, and minimal maintenance requirements. Nonetheless, the initial investment and the complexity of these systems necessitate a careful cost-benefit analysis tailored to specific operational demands. Adherence to strict quality standards and certifications is essential when selecting and employing vertical pump bearings. Reputable manufacturers adhere to international standards such as ISO, ASTM, and DIN, ensuring the bearings have undergone rigorous testing for quality and performance. Sourcing from established suppliers with a proven track record enhances the trustworthiness of the bearings' performance, offering peace of mind in critical industrial applications. Collaborating with engineering experts and consultants is recommended for optimizing bearing selection and pump design. These professionals provide invaluable insight into material science, fluid dynamics, and mechanical engineering, guiding you through complex decisions that impact efficiency and performance. Leveraging their expertise ensures that the bear biophysical, environmental, and economic aspects are adequately considered. In conclusion, vertical pump bearings are fundamental to the operational efficacy and longevity of vertical pumps across myriad industrial applications. Their selection, installation, and maintenance demand a thorough understanding of mechanical principles and industry-specific requirements. By prioritizing reliability, efficiency, and expert guidance, businesses can enhance their pump systems' performance, ensuring a sustainable and cost-effective operation.

Upgrading to advanced bearing technologies can yield substantial performance improvements and cost savings. Innovations such as magnetic bearings eliminate physical contact, reducing friction and wear to nearly zero. These bearings are gaining popularity for their high efficiency, low energy consumption, and minimal maintenance requirements. Nonetheless, the initial investment and the complexity of these systems necessitate a careful cost-benefit analysis tailored to specific operational demands. Adherence to strict quality standards and certifications is essential when selecting and employing vertical pump bearings. Reputable manufacturers adhere to international standards such as ISO, ASTM, and DIN, ensuring the bearings have undergone rigorous testing for quality and performance. Sourcing from established suppliers with a proven track record enhances the trustworthiness of the bearings' performance, offering peace of mind in critical industrial applications. Collaborating with engineering experts and consultants is recommended for optimizing bearing selection and pump design. These professionals provide invaluable insight into material science, fluid dynamics, and mechanical engineering, guiding you through complex decisions that impact efficiency and performance. Leveraging their expertise ensures that the bear biophysical, environmental, and economic aspects are adequately considered. In conclusion, vertical pump bearings are fundamental to the operational efficacy and longevity of vertical pumps across myriad industrial applications. Their selection, installation, and maintenance demand a thorough understanding of mechanical principles and industry-specific requirements. By prioritizing reliability, efficiency, and expert guidance, businesses can enhance their pump systems' performance, ensuring a sustainable and cost-effective operation.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024