-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 11:25

Back to list

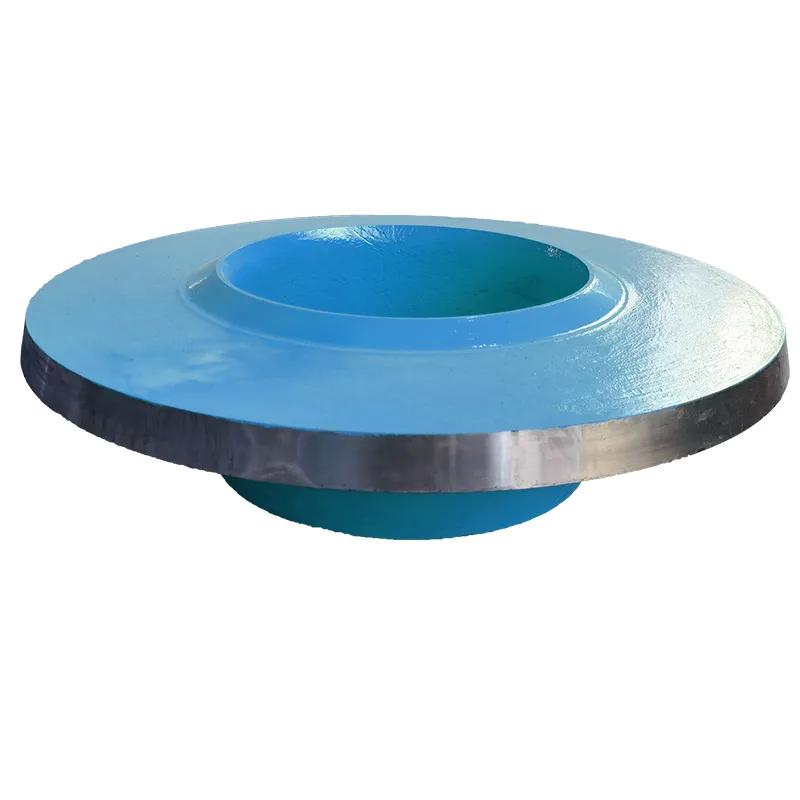

clutch bearing assembly

Clutch bearing assemblies play an integral role in the smooth operation of vehicles and various machinery. These crucial components are responsible for handling the stress and friction during gear shifts, enabling precise and efficient power transmission. Their importance cannot be understated, as they directly impact the performance and longevity of both the clutch system and the machinery itself.

In the context of maintenance, regular inspection of the clutch bearing assembly is recommended. Bearings should be checked for signs of wear, such as scoring or excessive play, both of which could indicate the need for replacement. Routine lubrication, where applicable, can also extend the lifespan of the bearing by reducing friction and minimizing heat buildup. Relying on authoritative sources for maintenance procedures ensures that the clutch bearing remains in peak condition. Trustworthiness in the selection and use of clutch bearing assemblies stems from sourcing quality components from reputable manufacturers. Brands with a proven track record in engineering durable and efficient bearings can provide peace of mind and assurance of performance standards. Online reviews, industry publications, and expert recommendations can serve as reliable resources when choosing a manufacturer. For those involved in the automotive or industrial sectors, staying informed about the latest advancements in clutch bearing technology is beneficial. Innovations such as integrated sensors for real-time monitoring or advanced materials designed to withstand extreme conditions continue to evolve. Engaging with professional communities or attending industry events can provide valuable insights into future trends and developments. In conclusion, clutch bearing assemblies demand a comprehensive understanding of type selection, material choice, proper installation, and routine maintenance. By leveraging expertise and authoritative guidance, and ensuring trustworthiness in component sourcing, businesses and individuals can optimize the performance and lifespan of their clutch systems. Continuous learning and adaptation to new technologies will further enhance the efficiencies achieved through these vital components.

In the context of maintenance, regular inspection of the clutch bearing assembly is recommended. Bearings should be checked for signs of wear, such as scoring or excessive play, both of which could indicate the need for replacement. Routine lubrication, where applicable, can also extend the lifespan of the bearing by reducing friction and minimizing heat buildup. Relying on authoritative sources for maintenance procedures ensures that the clutch bearing remains in peak condition. Trustworthiness in the selection and use of clutch bearing assemblies stems from sourcing quality components from reputable manufacturers. Brands with a proven track record in engineering durable and efficient bearings can provide peace of mind and assurance of performance standards. Online reviews, industry publications, and expert recommendations can serve as reliable resources when choosing a manufacturer. For those involved in the automotive or industrial sectors, staying informed about the latest advancements in clutch bearing technology is beneficial. Innovations such as integrated sensors for real-time monitoring or advanced materials designed to withstand extreme conditions continue to evolve. Engaging with professional communities or attending industry events can provide valuable insights into future trends and developments. In conclusion, clutch bearing assemblies demand a comprehensive understanding of type selection, material choice, proper installation, and routine maintenance. By leveraging expertise and authoritative guidance, and ensuring trustworthiness in component sourcing, businesses and individuals can optimize the performance and lifespan of their clutch systems. Continuous learning and adaptation to new technologies will further enhance the efficiencies achieved through these vital components.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024