-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 30, 2025 00:33

Back to list

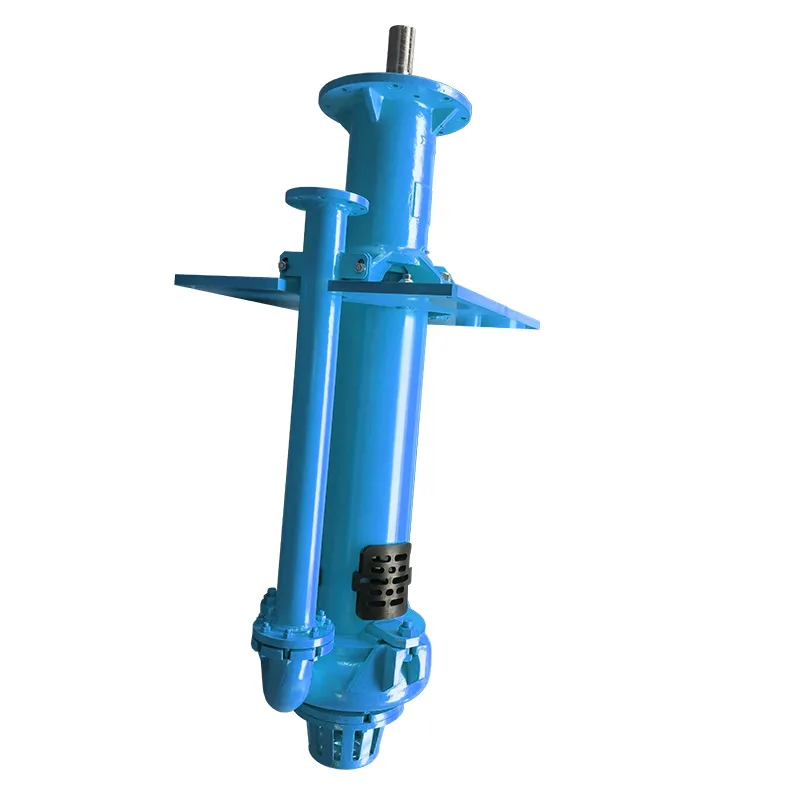

vertical multistage pump

Vertical multistage pumps have increasingly become indispensable components across various industries, thanks to their high efficiency, compact design, and versatile utility. When it comes to managing fluid transportation systems, these pumps offer a seamless blend of performance and reliability that is hard to match.

Trustworthiness is another facet where vertical multistage pumps excel, primarily due to their consistent performance in critical applications. Municipal water supply systems, for instance, rely heavily on these pumps for their ability to handle large volumes with minimal downtime. Case studies reflect their robust construction and design, which significantly reduce the risks of mechanical failure, ensuring uninterrupted service in essential water distribution networks. When integrating a vertical multistage pump into your system, considering the specific flow rates, height of operation, and the chemical nature of the fluid is vital. Not all multistage pumps are alike, and factors such as the number of stages, type of impeller, and material of construction play a decisive role in matching pumps to applications. Materials like stainless steel offer resistance to corrosion, making them suitable for aggressive and demanding environments. Despite their myriad advantages, installing a vertical multistage pump can be a significant investment. Therefore, long-term cost analysis should not only consider the initial purchase and installation costs but also the potential savings in energy and maintenance over time. Advanced features such as smart sensors and variable frequency drives can further optimize performance, aligning operations with sustainability goals by reducing both the environmental footprint and operational costs. In conclusion, vertical multistage pumps represent a convergence of advanced engineering with practical utility, exemplifying resilience and efficiency. As industries continue to evolve, the adoption of such pumps symbolizes not just a commitment to meeting operational demands, but also to fostering sustainable and energy-efficient practices. With the proper selection, installation, and maintenance, vertical multistage pumps prove to be an invaluable asset in modern fluid management systems, cementing their role as a cornerstone of industrial and commercial infrastructures.

Trustworthiness is another facet where vertical multistage pumps excel, primarily due to their consistent performance in critical applications. Municipal water supply systems, for instance, rely heavily on these pumps for their ability to handle large volumes with minimal downtime. Case studies reflect their robust construction and design, which significantly reduce the risks of mechanical failure, ensuring uninterrupted service in essential water distribution networks. When integrating a vertical multistage pump into your system, considering the specific flow rates, height of operation, and the chemical nature of the fluid is vital. Not all multistage pumps are alike, and factors such as the number of stages, type of impeller, and material of construction play a decisive role in matching pumps to applications. Materials like stainless steel offer resistance to corrosion, making them suitable for aggressive and demanding environments. Despite their myriad advantages, installing a vertical multistage pump can be a significant investment. Therefore, long-term cost analysis should not only consider the initial purchase and installation costs but also the potential savings in energy and maintenance over time. Advanced features such as smart sensors and variable frequency drives can further optimize performance, aligning operations with sustainability goals by reducing both the environmental footprint and operational costs. In conclusion, vertical multistage pumps represent a convergence of advanced engineering with practical utility, exemplifying resilience and efficiency. As industries continue to evolve, the adoption of such pumps symbolizes not just a commitment to meeting operational demands, but also to fostering sustainable and energy-efficient practices. With the proper selection, installation, and maintenance, vertical multistage pumps prove to be an invaluable asset in modern fluid management systems, cementing their role as a cornerstone of industrial and commercial infrastructures.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024