-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 29, 2025 05:55

Back to list

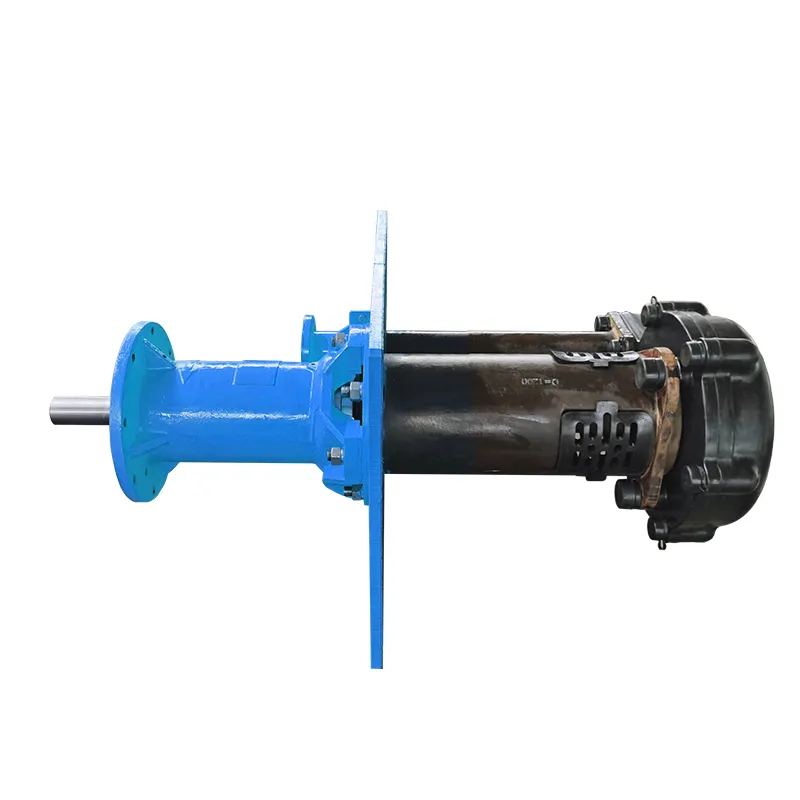

vertical centrifugal pump

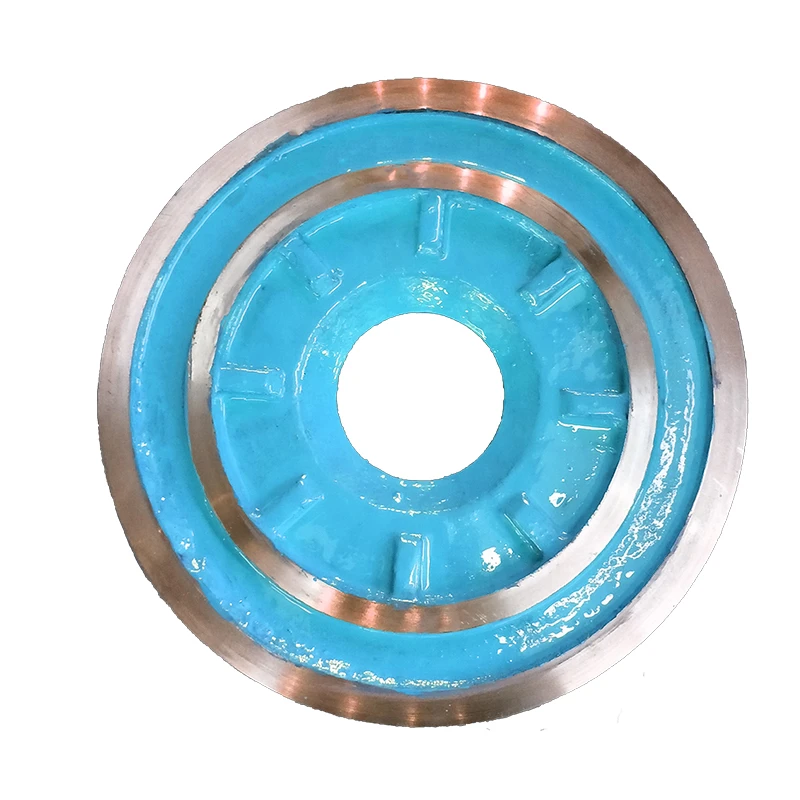

Vertical centrifugal pumps are integral to various industrial applications due to their unique design and operational efficiency. Known for their ability to handle high flow rates with a relatively steady output, they are essential in industries such as water treatment, chemical processing, and oil and gas. This article explores the nuances that make vertical centrifugal pumps indispensable, focusing on their design, efficiency, and the expert know-how required to optimize their use.

The authoritative expertise surrounding vertical centrifugal pumps is also reflected in the advancements in auxiliary system integrations. Today’s pumps can be part of larger automated systems, often controlled and monitored through sophisticated industrial control software. This integration not only enhances operational efficiency but also contributes to preventive maintenance practices. By monitoring key performance indicators such as vibration, temperature, and pressure, maintenance teams can preemptively address potential issues, minimizing downtime and extending the life of the pump system. Knowledge of these systems and the ability to interpret performance data are hallmarks of authoritative expertise in pump management. Finally, trustworthiness in the application of vertical centrifugal pumps is achieved through adherence to stringent industry standards and certifications. These pumps are often certified to operate under specific industry norms, ensuring their reliability and safety in various applications. Operators and engineers must be familiar with these standards to ensure compliance and maintain operational integrity. In conclusion, vertical centrifugal pumps are not only a testament to engineering ingenuity but also a benchmark for operational reliability and efficiency across various industries. Mastery in their application necessitates a profound understanding of their design and operational principles combined with a commitment to continuous learning and adaptation to technological advances. Through expert management, these pumps continue to play a vital role in industrial operations worldwide, delivering not just fluid but also sustainable and reliable performance.

The authoritative expertise surrounding vertical centrifugal pumps is also reflected in the advancements in auxiliary system integrations. Today’s pumps can be part of larger automated systems, often controlled and monitored through sophisticated industrial control software. This integration not only enhances operational efficiency but also contributes to preventive maintenance practices. By monitoring key performance indicators such as vibration, temperature, and pressure, maintenance teams can preemptively address potential issues, minimizing downtime and extending the life of the pump system. Knowledge of these systems and the ability to interpret performance data are hallmarks of authoritative expertise in pump management. Finally, trustworthiness in the application of vertical centrifugal pumps is achieved through adherence to stringent industry standards and certifications. These pumps are often certified to operate under specific industry norms, ensuring their reliability and safety in various applications. Operators and engineers must be familiar with these standards to ensure compliance and maintain operational integrity. In conclusion, vertical centrifugal pumps are not only a testament to engineering ingenuity but also a benchmark for operational reliability and efficiency across various industries. Mastery in their application necessitates a profound understanding of their design and operational principles combined with a commitment to continuous learning and adaptation to technological advances. Through expert management, these pumps continue to play a vital role in industrial operations worldwide, delivering not just fluid but also sustainable and reliable performance.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024