-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 03, 2025 01:53

Back to list

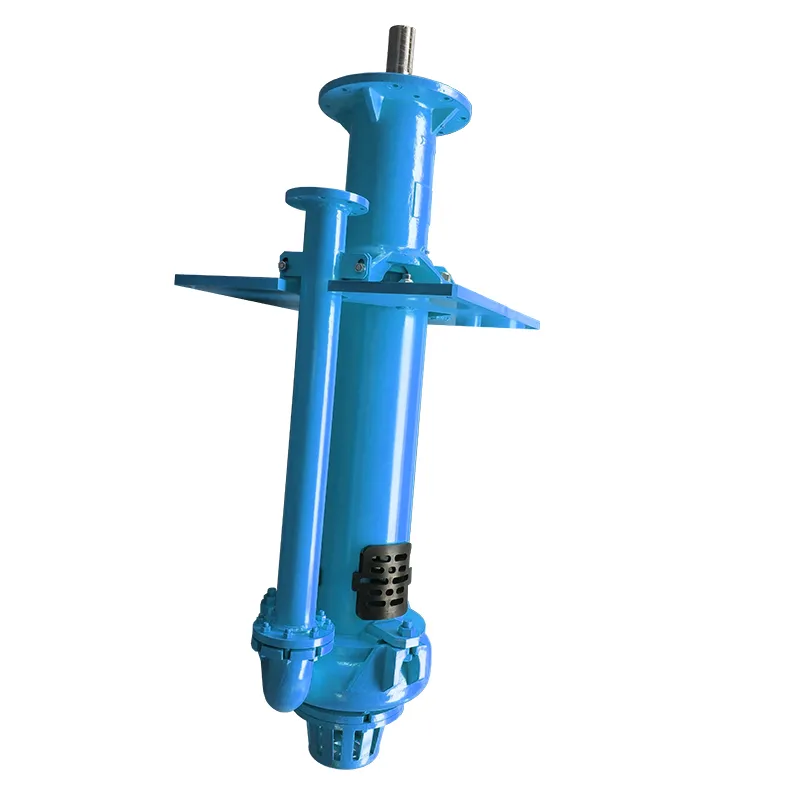

vertical multistage centrifugal pump parts

Understanding the intricacies of vertical multistage centrifugal pump parts is essential for anyone involved in industries where fluid movement is pivotal. These pumps are a mainstay in applications such as water treatment, HVAC, and industrial processing, offering superior performance and efficiency. A comprehensive exploration of their components will empower you with the knowledge to enhance operational longevity and reliability.

The shaft of a vertical multistage centrifugal pump plays an indispensable role by transmitting the motor's mechanical energy to the impellers. The material choice for shafts—commonly stainless steel or high-strength alloys—determines the pump’s capability to handle stress and resist wear. In high-capacity pumps, shafts might be engineered with specific coatings to enhance longevity and reduce maintenance intervals. Motor couplings should not be underestimated. They connect the motor and pump, transmitting torque while accommodating slight misalignments. High-quality couplings are essential for vibration reduction and operational efficiency, protecting both the motor and the pump from undue stress. Bearings, though less glamorous among pump components, are critical for stable and efficient operation. They minimize friction between moving parts, supporting the rotational movement of the shaft and impellers. Bearings typically require precise lubrication to function optimally. Choosing the right lubrication method and materials can significantly extend the lifespan of the bearings and, by extension, the pump itself. Every part of a vertical multistage centrifugal pump must harmonize to deliver peak performance. Selection, installation, and maintenance are key areas where expertise significantly impacts operational success. Professionals with extensive experience and deep understanding of fluid dynamics and pump mechanics will recognize the signs of wear and potential failure, allowing for preventative measures to be taken before issues arise. By embracing a comprehensive understanding of vertical multistage centrifugal pump parts, industries can optimize performance, minimize costs, and ensure fluid movement is both efficient and reliable. Increasing your expertise in each component will provide the foundation for developing a robust pump management strategy, ensuring unparalleled operational integrity and trustworthiness in your pumping systems.

The shaft of a vertical multistage centrifugal pump plays an indispensable role by transmitting the motor's mechanical energy to the impellers. The material choice for shafts—commonly stainless steel or high-strength alloys—determines the pump’s capability to handle stress and resist wear. In high-capacity pumps, shafts might be engineered with specific coatings to enhance longevity and reduce maintenance intervals. Motor couplings should not be underestimated. They connect the motor and pump, transmitting torque while accommodating slight misalignments. High-quality couplings are essential for vibration reduction and operational efficiency, protecting both the motor and the pump from undue stress. Bearings, though less glamorous among pump components, are critical for stable and efficient operation. They minimize friction between moving parts, supporting the rotational movement of the shaft and impellers. Bearings typically require precise lubrication to function optimally. Choosing the right lubrication method and materials can significantly extend the lifespan of the bearings and, by extension, the pump itself. Every part of a vertical multistage centrifugal pump must harmonize to deliver peak performance. Selection, installation, and maintenance are key areas where expertise significantly impacts operational success. Professionals with extensive experience and deep understanding of fluid dynamics and pump mechanics will recognize the signs of wear and potential failure, allowing for preventative measures to be taken before issues arise. By embracing a comprehensive understanding of vertical multistage centrifugal pump parts, industries can optimize performance, minimize costs, and ensure fluid movement is both efficient and reliable. Increasing your expertise in each component will provide the foundation for developing a robust pump management strategy, ensuring unparalleled operational integrity and trustworthiness in your pumping systems.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024