-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 03, 2025 01:39

Back to list

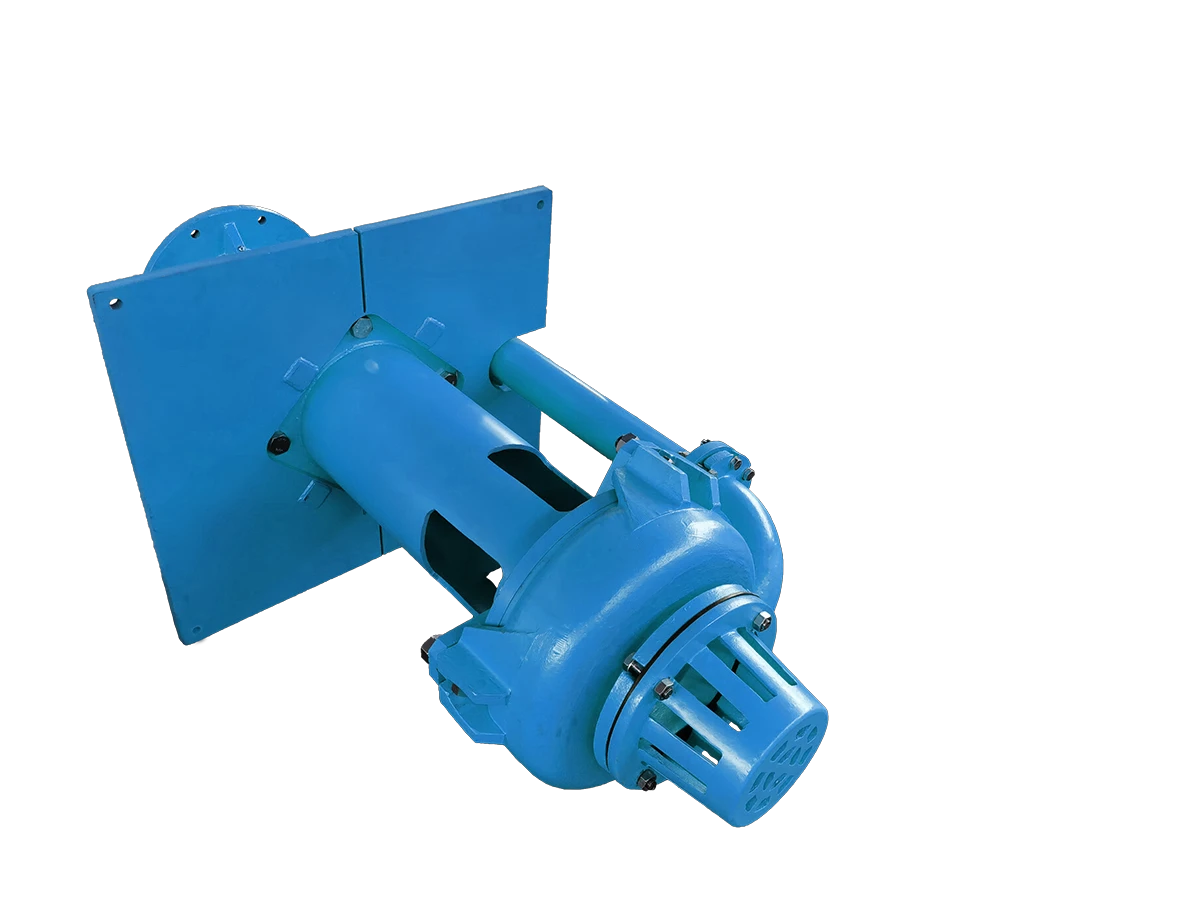

vertical centrifugal pump pdf

Vertical centrifugal pumps have increasingly become an indispensable component in various industrial applications due to their unique design and functional benefits. These pumps are engineered to move fluids efficiently across different heads and volumes, making their design a central talking point among fluid handling engineers. Consequently, as industries pivot towards more sustainable and efficient methodologies, understanding the intricacies of vertical centrifugal pumps becomes essential.

Trustworthiness within the use and functionality of vertical centrifugal pumps is further cemented by rigorous testing processes and empirical case studies. For instance, before deployment, these pumps undergo extensive performance tests to evaluate their handling of different fluid types and their efficiency across varying operational conditions. Real-life applications, such as in municipal water treatment or chemical manufacturing plants, provide valuable data. These case studies serve as testament to the pump's reliability and efficiency, giving purchasers the confidence in their decision to invest in such technology. Additionally, one cannot overlook the progressive shift toward digitalization in pump technology. Innovative features such as IoT (Internet of Things) integration allow for real-time monitoring and predictive maintenance. This technology permits operators to identify potential disruptions before they become significant issues, thus optimizing uptime and performance. Industry experts advocate for these developments as they not only drive efficiency but also align with broader trends in industrial automation and smart technology deployment. In conclusion, the vertical centrifugal pump stands as a paragon of modern engineering within the fluid management sector. Its benefits are manifest not only in its spatial efficiency and durability but also in the assurance it offers through compliance with esteemed industry standards. As technology advances and industries demand more from their equipment, the vertical centrifugal pump's design and functionality will undoubtedly continue to evolve, offering even greater efficiencies and applications. For any enterprise looking to optimize its fluid handling systems, understanding and investing in these pumps translates to long-term savings and robust performance.

Trustworthiness within the use and functionality of vertical centrifugal pumps is further cemented by rigorous testing processes and empirical case studies. For instance, before deployment, these pumps undergo extensive performance tests to evaluate their handling of different fluid types and their efficiency across varying operational conditions. Real-life applications, such as in municipal water treatment or chemical manufacturing plants, provide valuable data. These case studies serve as testament to the pump's reliability and efficiency, giving purchasers the confidence in their decision to invest in such technology. Additionally, one cannot overlook the progressive shift toward digitalization in pump technology. Innovative features such as IoT (Internet of Things) integration allow for real-time monitoring and predictive maintenance. This technology permits operators to identify potential disruptions before they become significant issues, thus optimizing uptime and performance. Industry experts advocate for these developments as they not only drive efficiency but also align with broader trends in industrial automation and smart technology deployment. In conclusion, the vertical centrifugal pump stands as a paragon of modern engineering within the fluid management sector. Its benefits are manifest not only in its spatial efficiency and durability but also in the assurance it offers through compliance with esteemed industry standards. As technology advances and industries demand more from their equipment, the vertical centrifugal pump's design and functionality will undoubtedly continue to evolve, offering even greater efficiencies and applications. For any enterprise looking to optimize its fluid handling systems, understanding and investing in these pumps translates to long-term savings and robust performance.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024