-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 18:04

Back to list

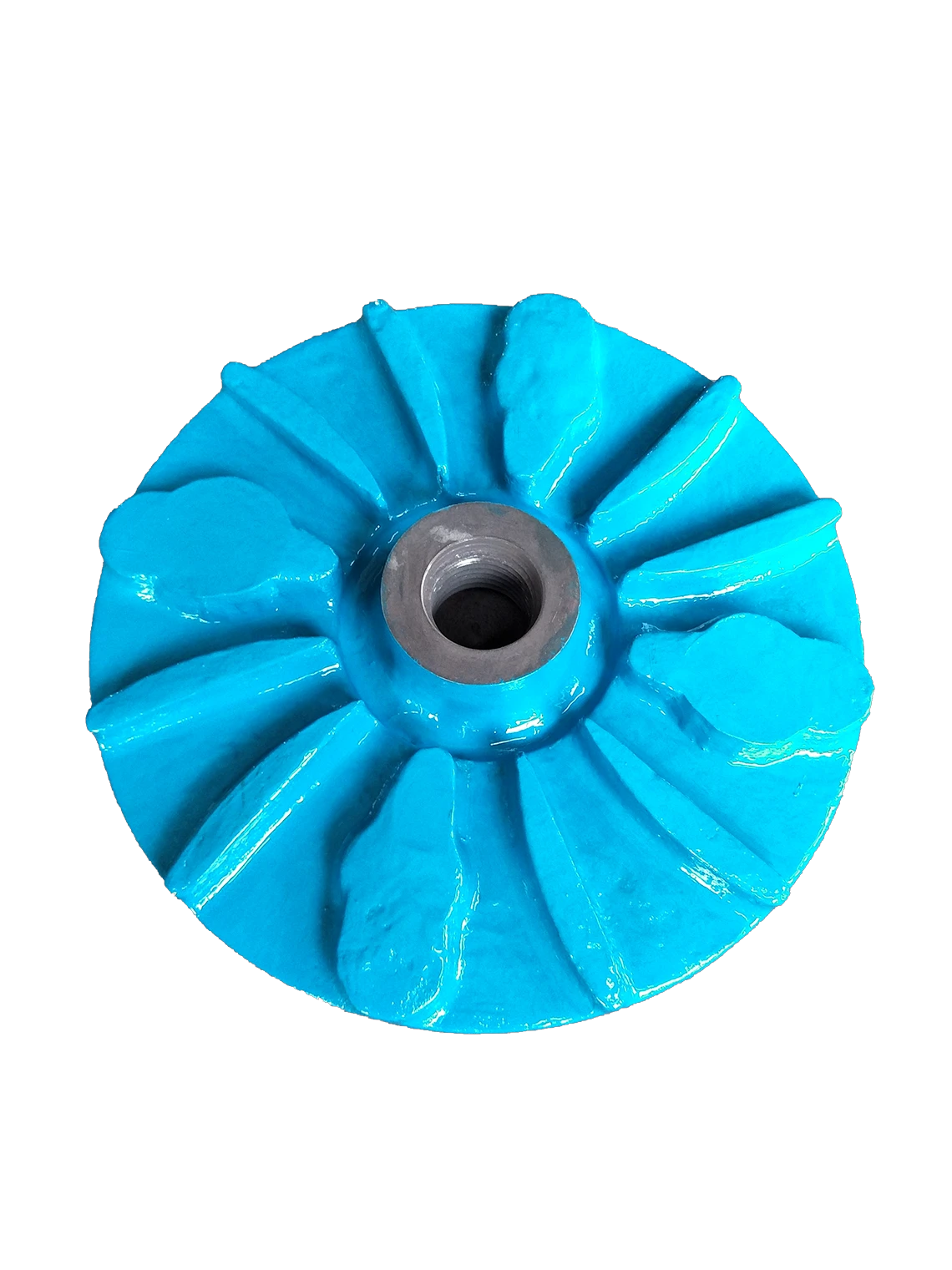

Horizontal Slurry Pumps MM1.5/1B-AHR

Harnessing the potential of a vacuum impeller design can significantly elevate the efficiency and performance of vacuum systems, making it a focal point for engineers and product developers striving for innovation. An impeccable design hinges on a seamless blend of engineering prowess and real-world application results, ensuring that the device not only functions optimally but also stands the test of time.

Consideration of the operating environment tremendously influences the choice of vacuum impeller design. Engineers must factor in whether the system needs to operate in explosive, corrosive, or high-temperature environments. For example, impellers designed for high-temperature applications might incorporate advanced cooling systems or utilize specialty alloys that can withstand thermal expansion without deforming or losing efficiency. Real-world data and experience feed into refining impeller design. System simulations and prototypes allow engineers to test theories and spot potential issues before committing to a final design. Automated modeling and computational fluid dynamics (CFD) simulations are invaluable, providing insights into airflow patterns, pressure distribution, and the overall interaction between system components. However, field testing remains crucial, as real-world conditions often present challenges not visible in idealized simulations. To cement authority in the development of vacuum impellers, one must stay abreast of technological advancements and innovations. The integration of smart technology into equipment allows for the monitoring of performance metrics in real-time. Feedback systems can alert engineers to wear-and-tear or declining performance, enabling preemptive maintenance and adjustments, thus prolonging system life and maintaining efficiency. Collaboration with industry experts and researchers also enhances trustworthiness in vacuum impeller design. By exchanging insights and sharing breakthroughs, a designer not only strengthens their professional capabilities but also builds a network that endorses their expertise and authority. Engaging in industry conferences and contributing to reputable journals can establish credibility and position an expert as a leader in the field. In conclusion, vacuum impeller design is a sophisticated dance of engineering excellence, requiring deep technical expertise and a nuanced understanding of real-world applications. Upholding the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, designers can create products that not only meet current demands but push the boundaries of what vacuum systems can achieve. This commitment to quality and innovation ensures that both the products and the professionals who develop them remain at the forefront of the industry.

Consideration of the operating environment tremendously influences the choice of vacuum impeller design. Engineers must factor in whether the system needs to operate in explosive, corrosive, or high-temperature environments. For example, impellers designed for high-temperature applications might incorporate advanced cooling systems or utilize specialty alloys that can withstand thermal expansion without deforming or losing efficiency. Real-world data and experience feed into refining impeller design. System simulations and prototypes allow engineers to test theories and spot potential issues before committing to a final design. Automated modeling and computational fluid dynamics (CFD) simulations are invaluable, providing insights into airflow patterns, pressure distribution, and the overall interaction between system components. However, field testing remains crucial, as real-world conditions often present challenges not visible in idealized simulations. To cement authority in the development of vacuum impellers, one must stay abreast of technological advancements and innovations. The integration of smart technology into equipment allows for the monitoring of performance metrics in real-time. Feedback systems can alert engineers to wear-and-tear or declining performance, enabling preemptive maintenance and adjustments, thus prolonging system life and maintaining efficiency. Collaboration with industry experts and researchers also enhances trustworthiness in vacuum impeller design. By exchanging insights and sharing breakthroughs, a designer not only strengthens their professional capabilities but also builds a network that endorses their expertise and authority. Engaging in industry conferences and contributing to reputable journals can establish credibility and position an expert as a leader in the field. In conclusion, vacuum impeller design is a sophisticated dance of engineering excellence, requiring deep technical expertise and a nuanced understanding of real-world applications. Upholding the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, designers can create products that not only meet current demands but push the boundaries of what vacuum systems can achieve. This commitment to quality and innovation ensures that both the products and the professionals who develop them remain at the forefront of the industry.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024