-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 17:44

Back to list

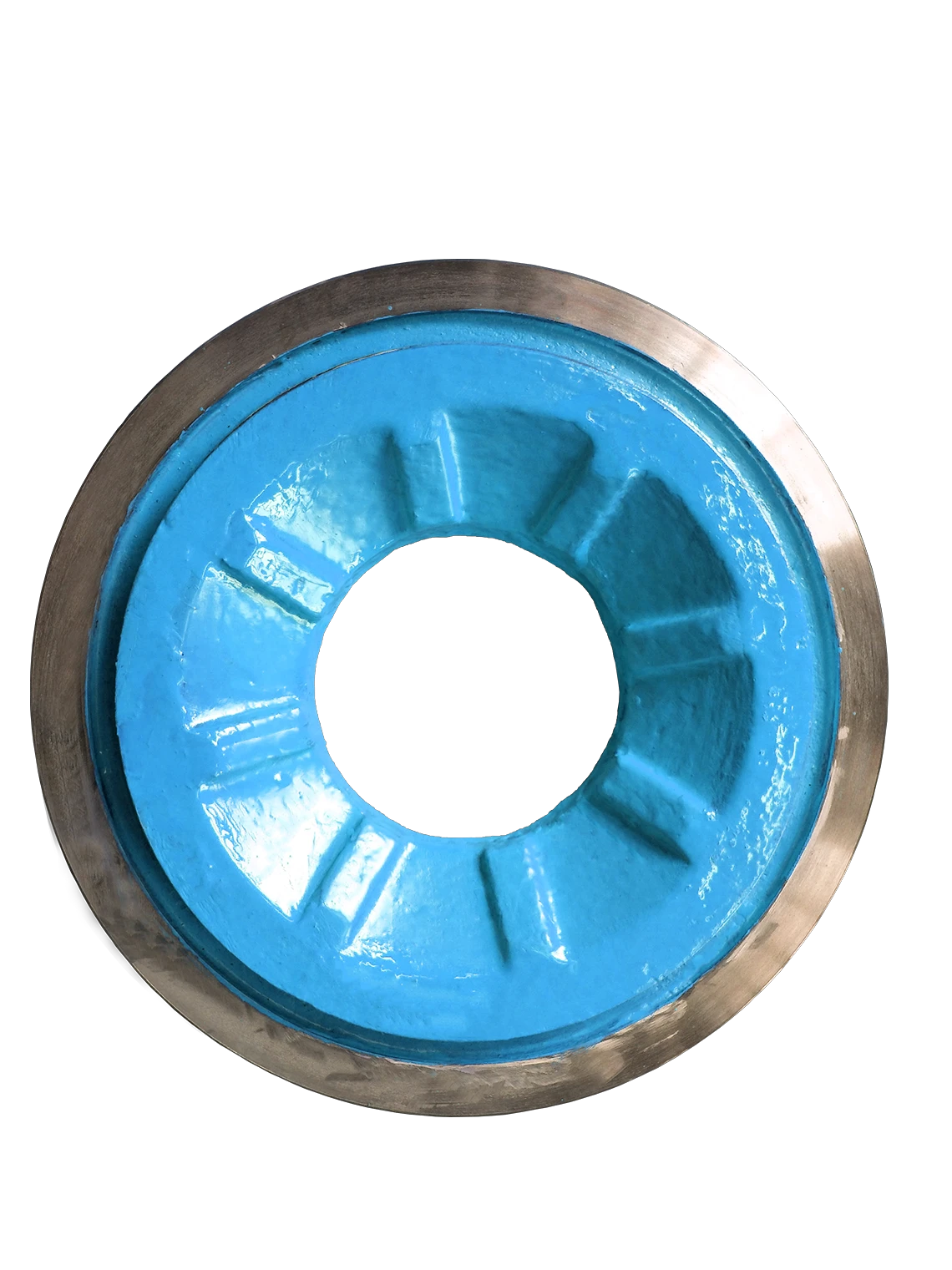

Pump Wear Parts C2127 Rubber

The choice of material for submersible pump impellers is crucial to the performance, durability, and efficiency of the pump. Different impeller materials can significantly influence the pump's resistance to corrosion, wear, and overall lifespan. Understanding these aspects allows for informed decision-making, particularly in industries where submersible pumps are critical.

Composite material impellers are increasingly popular due to advancements in material science. These composites can offer an optimal blend of properties such as high strength-to-weight ratios and excellent resistance to corrosion and chemical attack. They can be engineered to meet specific requirements, which is particularly useful in custom applications or when conventional materials fail to meet the necessary specifications. When selecting impeller materials, factors such as the nature of the fluid being pumped, operational environment, and expected lifespan must be considered. Consulting with experts and reviewing empirical data from specific applications can provide invaluable insights. For example, in environments where the fluid contains significant amounts of solids, abrasion-resistant materials like hardened stainless steel or special coatings may be necessary to extend the service life of the impeller. Innovations in surface treatments and coatings, such as ceramic or polymer coatings, have further expanded the capabilities of various impeller materials. These treatments can enhance the corrosion and wear resistance of a given material without significantly adding to the cost or complexity of the pump system. In conclusion, the selection of submersible pump impeller material is a nuanced decision that requires consideration of material properties, application requirements, and cost implications. By understanding the strengths and limitations of each material, businesses can ensure that their pump systems operate efficiently, reliably, and cost-effectively over their intended service life. Engaging with suppliers and industry experts who possess a deep understanding of these materials can provide companies with a competitive advantage, leading to optimal equipment performance and extended longevity.

Composite material impellers are increasingly popular due to advancements in material science. These composites can offer an optimal blend of properties such as high strength-to-weight ratios and excellent resistance to corrosion and chemical attack. They can be engineered to meet specific requirements, which is particularly useful in custom applications or when conventional materials fail to meet the necessary specifications. When selecting impeller materials, factors such as the nature of the fluid being pumped, operational environment, and expected lifespan must be considered. Consulting with experts and reviewing empirical data from specific applications can provide invaluable insights. For example, in environments where the fluid contains significant amounts of solids, abrasion-resistant materials like hardened stainless steel or special coatings may be necessary to extend the service life of the impeller. Innovations in surface treatments and coatings, such as ceramic or polymer coatings, have further expanded the capabilities of various impeller materials. These treatments can enhance the corrosion and wear resistance of a given material without significantly adding to the cost or complexity of the pump system. In conclusion, the selection of submersible pump impeller material is a nuanced decision that requires consideration of material properties, application requirements, and cost implications. By understanding the strengths and limitations of each material, businesses can ensure that their pump systems operate efficiently, reliably, and cost-effectively over their intended service life. Engaging with suppliers and industry experts who possess a deep understanding of these materials can provide companies with a competitive advantage, leading to optimal equipment performance and extended longevity.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024