-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 03:16

Back to list

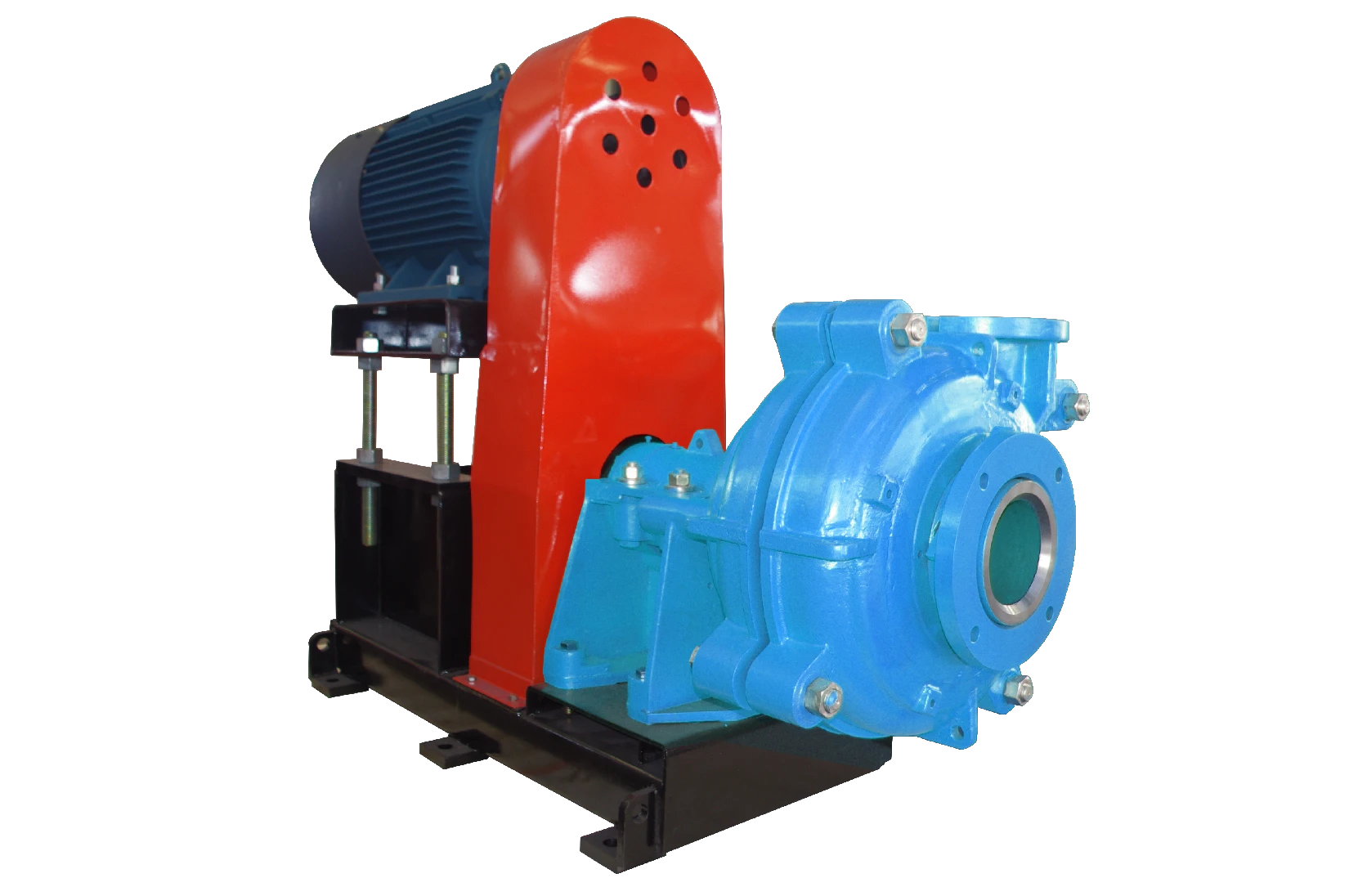

Pump Wear Parts FH4110 Metal

Small sludge pumps are essential tools in various industries where handling thick, slurry-like materials is required. Their specialized designs cater to unique operational demands that make them indispensable in fields like wastewater treatment, mining, and construction. This article delves into the intricate world of small sludge pumps, combining real-world experience, technical expertise, authority, and trustworthiness to offer an in-depth guide that not only educates but also optimizes for search engine visibility.

Selecting the right small sludge pump requires careful consideration of several factors. The specific gravity of the sludge, temperature, pH levels, and the presence of abrasive elements dictate the pump design and materials. Industry experts often stress the importance of understanding operational parameters to avoid issues such as cavitation, which can lead to costly repairs and increased downtime. Utilizing pumps with adjustable speed drives or integrated controllers allows for flexible operation and improved energy efficiency, aligning with sustainability goals. The deployment of small sludge pumps often requires customization to suit the particularities of a given project. Experienced engineers and technicians provide tailored solutions, incorporating features like variable frequency drives, remote monitoring capabilities, and automated control systems. Such advancements ensure that pumps adapt seamlessly to changing sludge compositions and process requirements, enhancing overall plant performance. A detailed understanding of maintenance practices further underscores the pump’s role in efficient plant operations. Professionals emphasize the importance of routine inspections and timely replacements of wear parts, such as seals, bearings, and impellers. A well-maintained pump not only extends its lifespan but also preserves the manufacturer's warranty, adding a layer of security for the investment. In conclusion, small sludge pumps are integral to maintaining operational efficiency and environment-friendly practices in industries dealing with viscous materials. By combining expert knowledge, hands-on experience, a reputable track record, and a foundation of trust, these pumping solutions cater to specific industrial needs while meeting the rigorous demands of modern environmental standards. A business contemplating the purchase of such equipment should prioritize comprehensive supplier evaluation, consider technological advancements, and consult with industry veterans to secure a pump solution that integrates seamlessly and operates efficiently within their established framework.

Selecting the right small sludge pump requires careful consideration of several factors. The specific gravity of the sludge, temperature, pH levels, and the presence of abrasive elements dictate the pump design and materials. Industry experts often stress the importance of understanding operational parameters to avoid issues such as cavitation, which can lead to costly repairs and increased downtime. Utilizing pumps with adjustable speed drives or integrated controllers allows for flexible operation and improved energy efficiency, aligning with sustainability goals. The deployment of small sludge pumps often requires customization to suit the particularities of a given project. Experienced engineers and technicians provide tailored solutions, incorporating features like variable frequency drives, remote monitoring capabilities, and automated control systems. Such advancements ensure that pumps adapt seamlessly to changing sludge compositions and process requirements, enhancing overall plant performance. A detailed understanding of maintenance practices further underscores the pump’s role in efficient plant operations. Professionals emphasize the importance of routine inspections and timely replacements of wear parts, such as seals, bearings, and impellers. A well-maintained pump not only extends its lifespan but also preserves the manufacturer's warranty, adding a layer of security for the investment. In conclusion, small sludge pumps are integral to maintaining operational efficiency and environment-friendly practices in industries dealing with viscous materials. By combining expert knowledge, hands-on experience, a reputable track record, and a foundation of trust, these pumping solutions cater to specific industrial needs while meeting the rigorous demands of modern environmental standards. A business contemplating the purchase of such equipment should prioritize comprehensive supplier evaluation, consider technological advancements, and consult with industry veterans to secure a pump solution that integrates seamlessly and operates efficiently within their established framework.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024