-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 03:34

Back to list

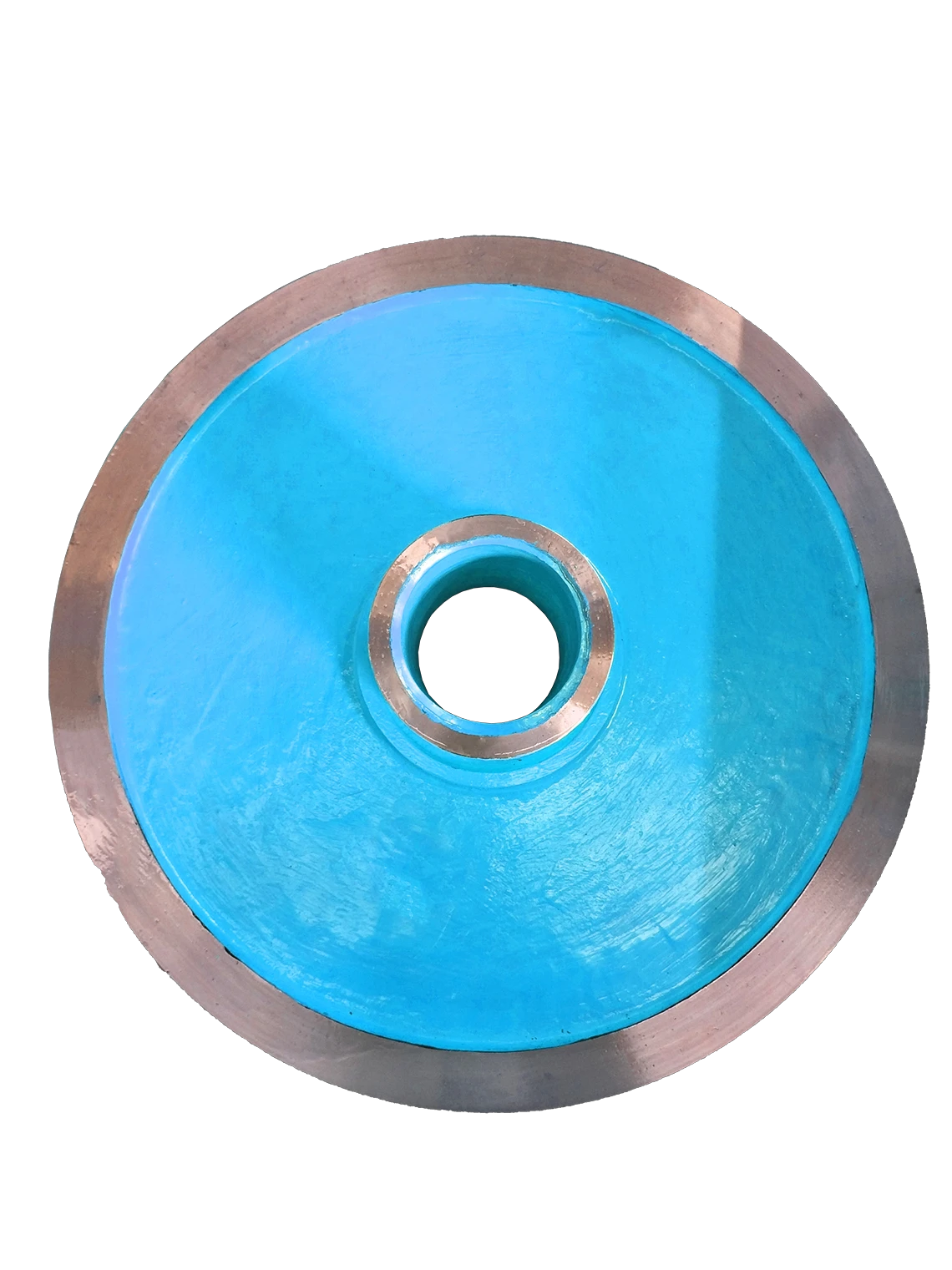

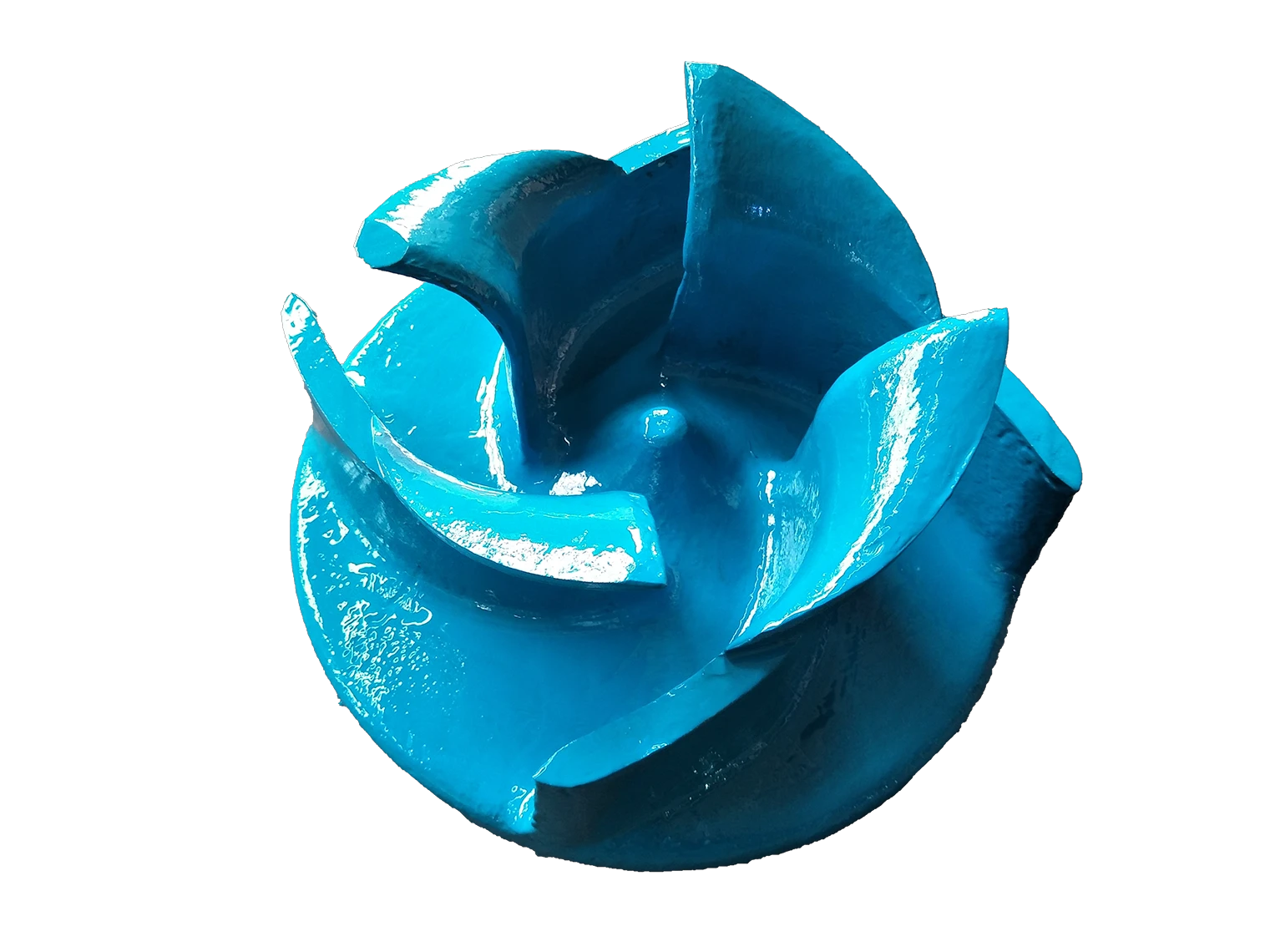

sludge transfer pump

Sludge transfer pumps are integral components in industries that manage heavy, viscous materials. These pumps ensure efficient movement of sludge—a semi-solid slurry composed of waste particles, often from industrial processes or wastewater treatment—between various process stages. Understanding the intricacies of selecting and operating these pumps can dramatically impact operational efficiency and environmental compliance.

Trustworthiness in sludge transfer pump operations is validated through adherence to industry standards and certifications. Ensuring that pumps meet rigorous international standards, such as the ISO or ASME certifications, reassures operators of their reliability and performance under varying operational conditions. Trust is also built through transparent operational reporting and compliance with environmental regulations, guaranteeing that systems are sustainable and environmentally friendly. From a practical, experiential standpoint, the operational success of sludge transfer pumps also hinges on regular maintenance and monitoring. Routine inspection and timely servicing are paramount to preemptive fault identification and rectification. Implementing sophisticated monitoring systems that track pump performance metrics, such as vibration analysis and hydraulic performance, allows for predictive maintenance strategies that prevent unexpected downtimes. Moreover, the adoption of digital solutions, particularly IoT-enabled pump systems, provides real-time insights and remote monitoring capabilities. This technological progression affords plant operators not only peace of mind but also the ability to optimize pump operations dynamically based on data-driven insights. In summary, sludge transfer pumps are essential in the movement and management of sludge in various industries. Expertise in their selection, installation, and maintenance ensures seamless and efficient operations. Authoritative best practices and adherence to trust-building industry standards bolster operational reliability. As industries continue to evolve, so too will the technologies that drive sludge management solutions, underscoring the ongoing need for innovation and expertise in this field.

Trustworthiness in sludge transfer pump operations is validated through adherence to industry standards and certifications. Ensuring that pumps meet rigorous international standards, such as the ISO or ASME certifications, reassures operators of their reliability and performance under varying operational conditions. Trust is also built through transparent operational reporting and compliance with environmental regulations, guaranteeing that systems are sustainable and environmentally friendly. From a practical, experiential standpoint, the operational success of sludge transfer pumps also hinges on regular maintenance and monitoring. Routine inspection and timely servicing are paramount to preemptive fault identification and rectification. Implementing sophisticated monitoring systems that track pump performance metrics, such as vibration analysis and hydraulic performance, allows for predictive maintenance strategies that prevent unexpected downtimes. Moreover, the adoption of digital solutions, particularly IoT-enabled pump systems, provides real-time insights and remote monitoring capabilities. This technological progression affords plant operators not only peace of mind but also the ability to optimize pump operations dynamically based on data-driven insights. In summary, sludge transfer pumps are essential in the movement and management of sludge in various industries. Expertise in their selection, installation, and maintenance ensures seamless and efficient operations. Authoritative best practices and adherence to trust-building industry standards bolster operational reliability. As industries continue to evolve, so too will the technologies that drive sludge management solutions, underscoring the ongoing need for innovation and expertise in this field.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024