-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 20, 2025 02:46

Back to list

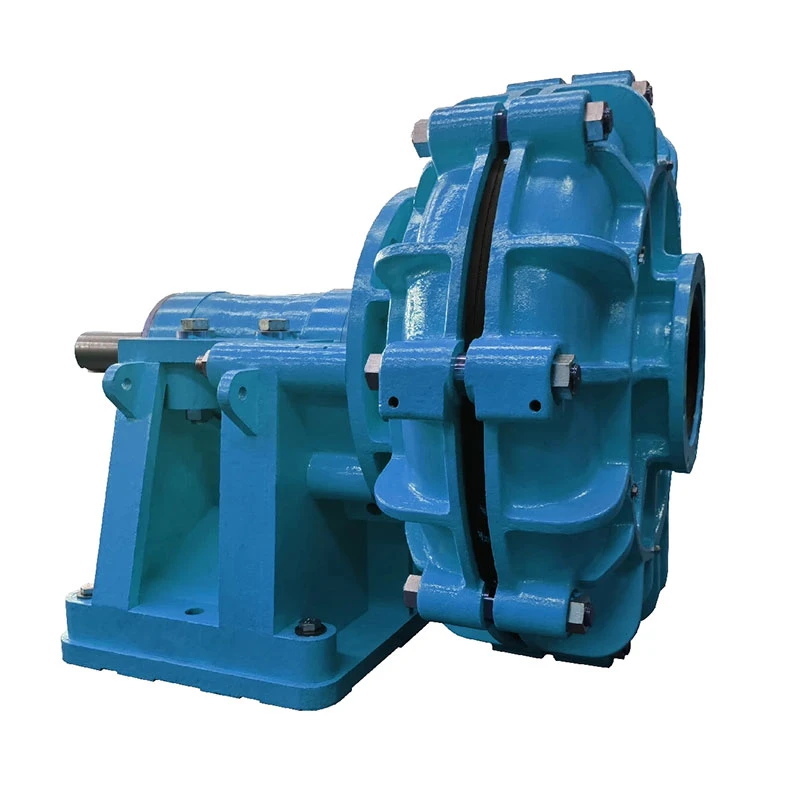

slurry water pump

In the industrial landscape, the slurry water pump stands as a pivotal component, driving efficiency across various sectors. With a unique ability to handle abrasive, viscous, and corrosive mediums, these pumps cater to industries ranging from mining to wastewater treatment with precision. Built to endure the strenuous demands of slurry handling, these pumps play a critical role, necessitating an understanding of their specific functions, advantages, and maintenance considerations.

Maintaining slurry water pumps is a testament to their trustworthiness. Regular inspection and maintenance ensure that these pumps perform at optimal levels, minimizing downtime and extending their service life. Using only manufacturer-recommended parts for replacements boosts performance consistency and reliability. For industries committed to sustainability, slurry pumps offer eco-friendly benefits. By efficiently separating solids from liquids, they reduce the environmental impact of waste disposal. This not only supports sustainability initiatives but also aligns with regulatory requirements, bolstering the pump's value in eco-conscious industries. In conclusion, the slurry water pump is more than just a tool—it's a cornerstone of efficiency in multiple industries. Its robust design, versatile applications, and adaptability make it an authoritative asset in any operation reliant on slurry transport. Trust in these pumps is well-placed, given their maintenance-friendly nature and sustainability benefits. For industries aiming to optimize production, minimize costs, and adhere to environmental standards, investing in high-quality slurry water pumps is a strategic decision.

Maintaining slurry water pumps is a testament to their trustworthiness. Regular inspection and maintenance ensure that these pumps perform at optimal levels, minimizing downtime and extending their service life. Using only manufacturer-recommended parts for replacements boosts performance consistency and reliability. For industries committed to sustainability, slurry pumps offer eco-friendly benefits. By efficiently separating solids from liquids, they reduce the environmental impact of waste disposal. This not only supports sustainability initiatives but also aligns with regulatory requirements, bolstering the pump's value in eco-conscious industries. In conclusion, the slurry water pump is more than just a tool—it's a cornerstone of efficiency in multiple industries. Its robust design, versatile applications, and adaptability make it an authoritative asset in any operation reliant on slurry transport. Trust in these pumps is well-placed, given their maintenance-friendly nature and sustainability benefits. For industries aiming to optimize production, minimize costs, and adhere to environmental standards, investing in high-quality slurry water pumps is a strategic decision.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024