-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 20, 2025 02:28

Back to list

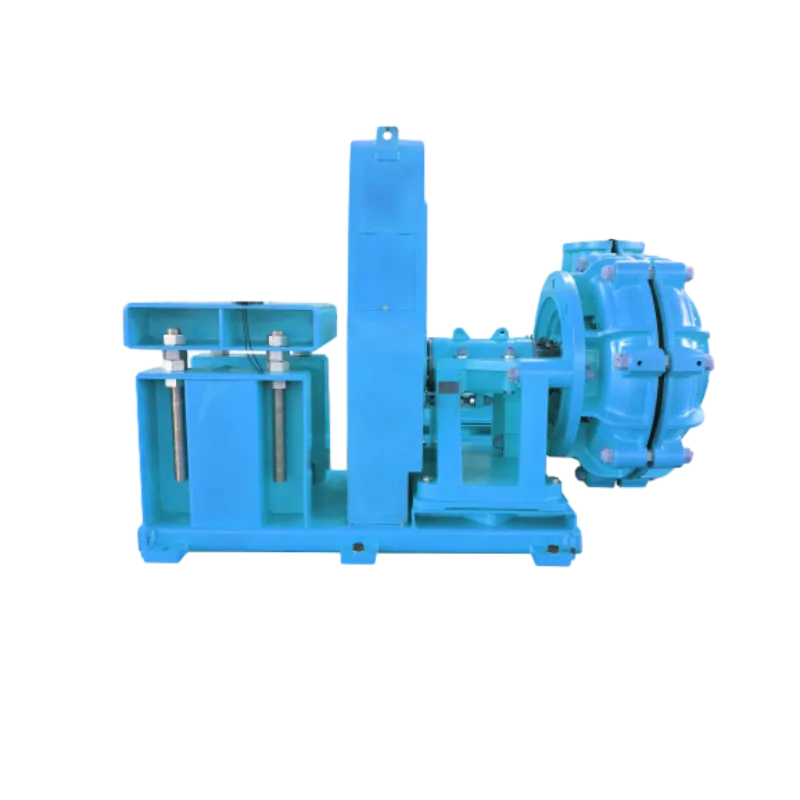

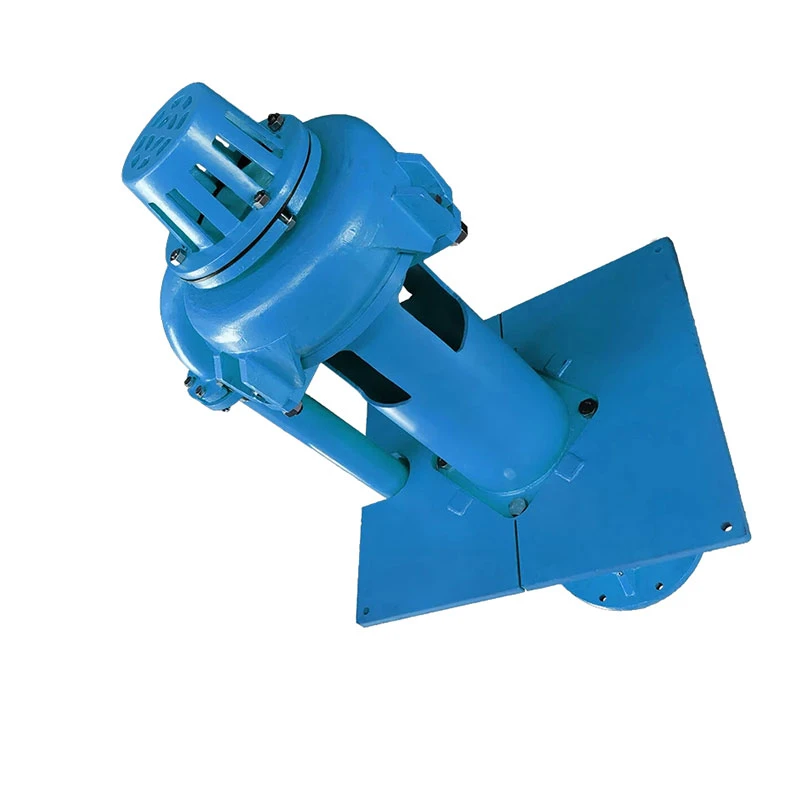

slurry tank pump

Selecting the right slurry tank pump can often seem overwhelming due to the variety of models, specifications, and technological innovations available on the market. This comprehensive guide is built upon years of industry expertise and is designed to offer authoritative insights into ensuring that industries ranging from agriculture to waste management can make informed decisions with a high degree of trust and confidence.

Moreover, energy efficiency is a major factor driving slurry tank pump innovation today. Efficient pumps reduce overall operational costs significantly by lowering energy consumption. Pumps with variable frequency drives (VFDs) allow for adjustable motor speeds, providing not only energy savings but also enhancing the pump's adaptability to varying operational demands. Examining case studies from industry leaders can provide further insights. For instance, a notable mining operation improved its slurry transport systems by integrating a series of high-capacity centrifugal pumps fitted with advanced wear liners. These modifications extended the pump lifecycle by 40%, resulting in substantial cost savings and reduced downtime. Such real-world applications highlight the importance of matching pump technology with specific operational requirements. To lend external validation and build trustworthiness, consulting certifications and standards while selecting slurry tank pumps is invaluable. Look for products compliant with ISO, ANSI, and other relevant certifications for quality and performance assurance. Engaging with manufacturers that possess a strong track record—reflected in case studies and client feedback—can ensure reliable and durable solutions. In conclusion, the intrinsic complexity of selecting slurry tank pumps can be mitigated through a comprehensive understanding of pump types, application requirements, and technological advancements. Expertise in these domains, backed by real-world applications and adherence to quality standards, can provide clear pathways to making educated decisions, reducing operational costs, optimizing performance, and ultimately ensuring the longevity and reliability of a plant's slurry management system. Trust in this tailored knowledge leads to greater operational efficiency and sustainable industrial practices.

Moreover, energy efficiency is a major factor driving slurry tank pump innovation today. Efficient pumps reduce overall operational costs significantly by lowering energy consumption. Pumps with variable frequency drives (VFDs) allow for adjustable motor speeds, providing not only energy savings but also enhancing the pump's adaptability to varying operational demands. Examining case studies from industry leaders can provide further insights. For instance, a notable mining operation improved its slurry transport systems by integrating a series of high-capacity centrifugal pumps fitted with advanced wear liners. These modifications extended the pump lifecycle by 40%, resulting in substantial cost savings and reduced downtime. Such real-world applications highlight the importance of matching pump technology with specific operational requirements. To lend external validation and build trustworthiness, consulting certifications and standards while selecting slurry tank pumps is invaluable. Look for products compliant with ISO, ANSI, and other relevant certifications for quality and performance assurance. Engaging with manufacturers that possess a strong track record—reflected in case studies and client feedback—can ensure reliable and durable solutions. In conclusion, the intrinsic complexity of selecting slurry tank pumps can be mitigated through a comprehensive understanding of pump types, application requirements, and technological advancements. Expertise in these domains, backed by real-world applications and adherence to quality standards, can provide clear pathways to making educated decisions, reducing operational costs, optimizing performance, and ultimately ensuring the longevity and reliability of a plant's slurry management system. Trust in this tailored knowledge leads to greater operational efficiency and sustainable industrial practices.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024