-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 01:04

Back to list

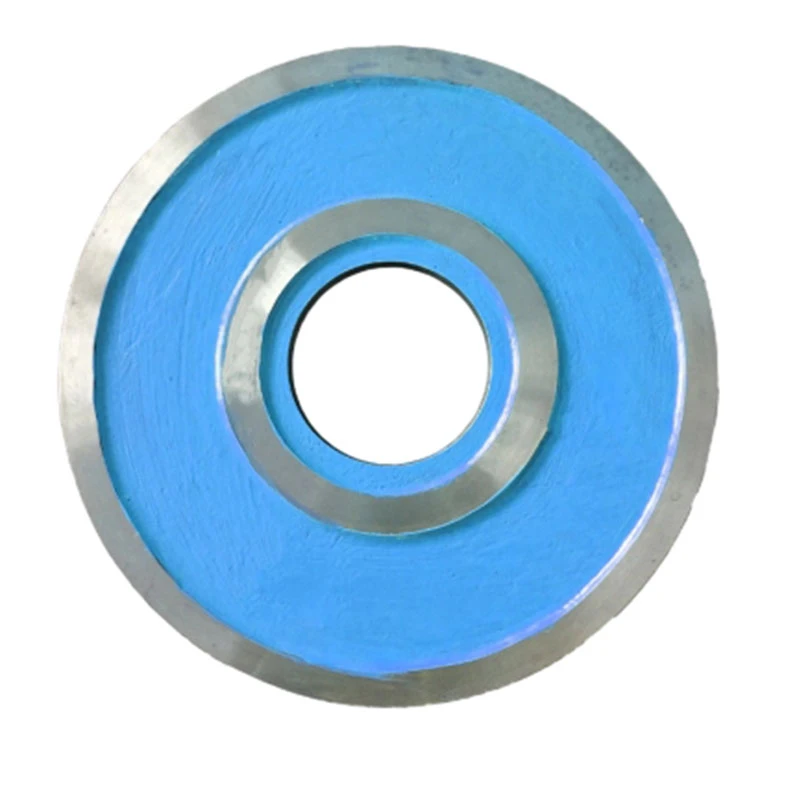

Pump Wear Parts B1052 Rubber

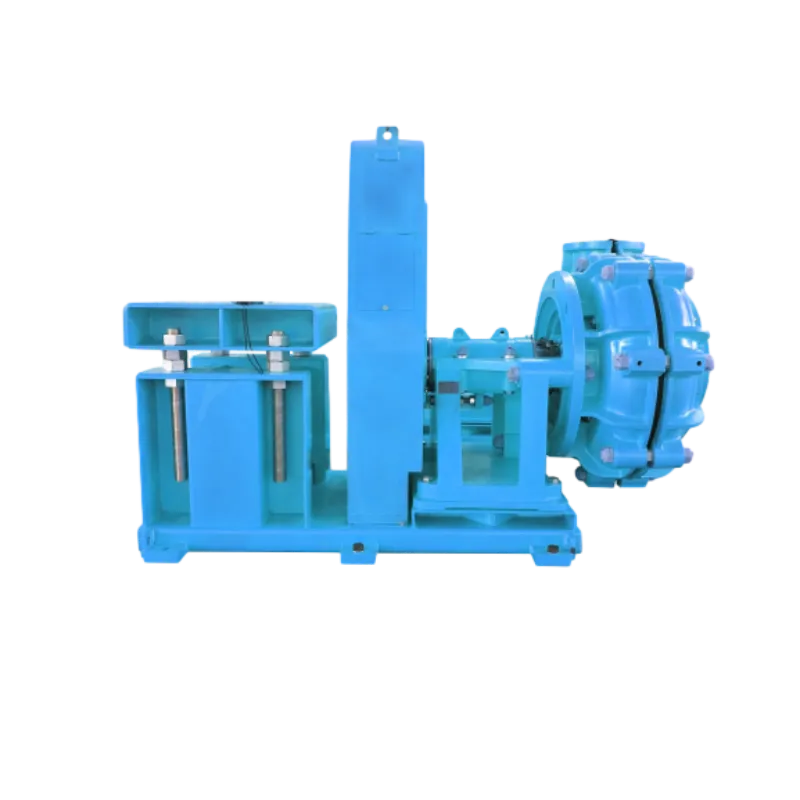

In the world of industrial fluid handling, slurry pumps stand as critical components across a variety of sectors ranging from mining to wastewater treatment. A key part of these pumps is the slurry pump volute liner, an element whose significance cannot be overstated. Understanding its role, materials, design, and maintenance is vital for anyone aiming for efficiency and longevity in pump operations.

Furthermore, advancements in material science and manufacturing techniques have led to the development of more durable and efficient volute liners. Modern computational fluid dynamics (CFD) simulations facilitate the design of liners that significantly reduce turbulence and wear. These technological improvements offer industries a way to manage operational costs more effectively while enhancing the performance of their slurry pumps. In an era where sustainability and efficiency are paramount, selecting the right slurry pump volute liner becomes a strategic decision. Companies are increasingly aware of the environmental impact of their operations and are striving to make processes more sustainable. Utilizing robust, high-performing volute liners ensures not only operational efficiency but also minimizes energy consumption and environmental impact over the lifespan of the pump. Trustworthy partnerships with reputable manufacturers and suppliers can be instrumental in acquiring volute liners that meet exact specifications and standards. It's important to work with suppliers who understand the application-specific requirements and provide tailored solutions that can withstand the rigorous demands of slurry pumping. In conclusion, the slurry pump volute liner is much more than a mere component within a pump. It is a pivotal element that significantly influences the efficiency, longevity, and sustainability of fluid handling processes. By understanding its materials, design requirements, and maintenance needs, companies can ensure they optimize performance while minimizing their environmental footprint. As industries continue to innovate and improve, the role of the volute liner will remain central, serving as a testament to the blend of engineering excellence and environmental stewardship.

Furthermore, advancements in material science and manufacturing techniques have led to the development of more durable and efficient volute liners. Modern computational fluid dynamics (CFD) simulations facilitate the design of liners that significantly reduce turbulence and wear. These technological improvements offer industries a way to manage operational costs more effectively while enhancing the performance of their slurry pumps. In an era where sustainability and efficiency are paramount, selecting the right slurry pump volute liner becomes a strategic decision. Companies are increasingly aware of the environmental impact of their operations and are striving to make processes more sustainable. Utilizing robust, high-performing volute liners ensures not only operational efficiency but also minimizes energy consumption and environmental impact over the lifespan of the pump. Trustworthy partnerships with reputable manufacturers and suppliers can be instrumental in acquiring volute liners that meet exact specifications and standards. It's important to work with suppliers who understand the application-specific requirements and provide tailored solutions that can withstand the rigorous demands of slurry pumping. In conclusion, the slurry pump volute liner is much more than a mere component within a pump. It is a pivotal element that significantly influences the efficiency, longevity, and sustainability of fluid handling processes. By understanding its materials, design requirements, and maintenance needs, companies can ensure they optimize performance while minimizing their environmental footprint. As industries continue to innovate and improve, the role of the volute liner will remain central, serving as a testament to the blend of engineering excellence and environmental stewardship.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024