-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 00:44

Back to list

Horizontal Slurry Pumps MM4/3D-AH

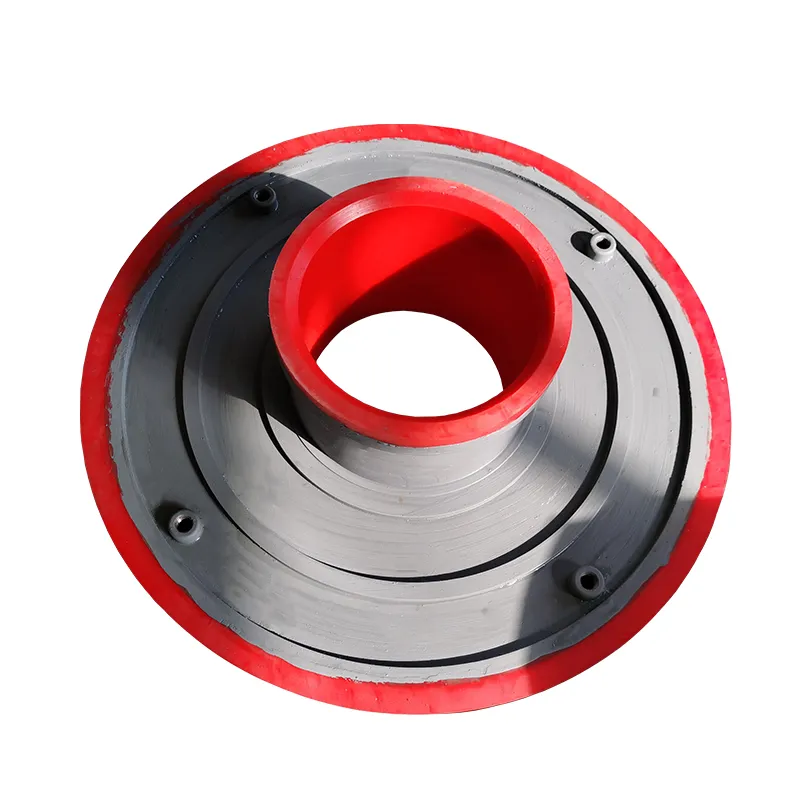

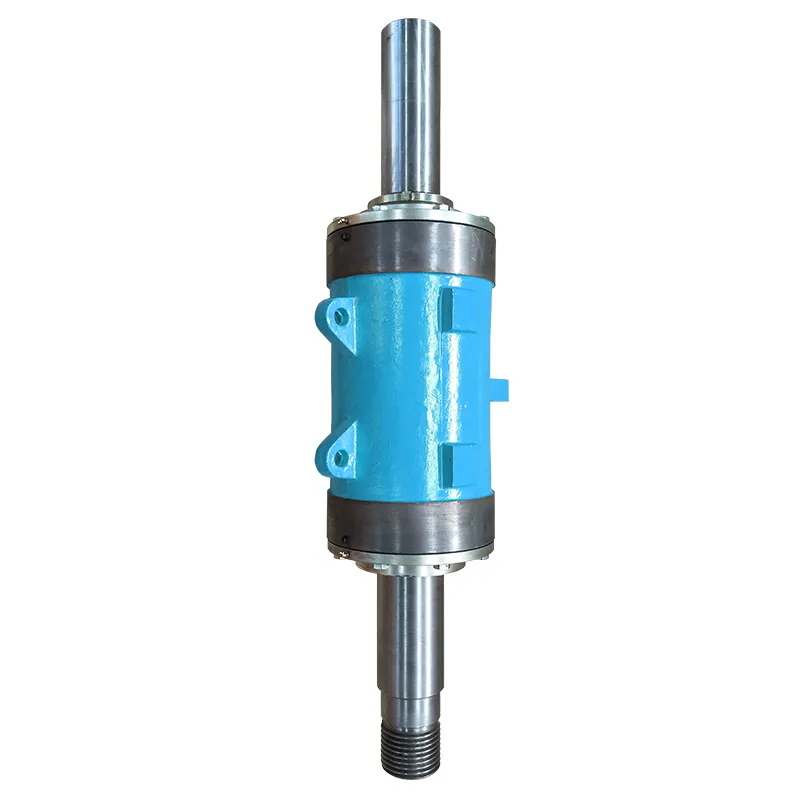

In the world of fluid dynamics, few components play a more critical role than pump volutes. These spiral casings—ingeniously designed to guide fluid into discharge pipes—are fundamental in maintaining the efficiency and longevity of pumps across various industries. As a seasoned SEO optimizer delving into this niche, it's imperative to explore the detailed dynamics, material considerations, and innovative advancements of pump volutes that make them pivotal in industrial applications.

Trust in pump volute design and manufacturing is cemented by rigorous standards and certifications. Organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) set benchmarks for design, safety, and performance. Ensuring compliance with these standards not only showcases a company's commitment to quality but also ensures clients receive products that meet or exceed regulatory expectations. Moreover, real-world case studies highlight the transformative impact of optimized volute designs. Consider an industrial wastewater treatment plant that, by upgrading to volutes tailored to handle high-viscosity slurries, saw a 25% boost in pump efficiency. This case exemplified the practical benefits of computational advancements and material improvements, underscoring the need for comprehensive expertise in selecting and designing volutes suitable for specific applications. The ongoing evolution of pump volute technology is a testament to the demand for improved energy efficiency and reduced ecological footprints. As industries strive to lower energy consumption and emissions, the role of efficiently designed volutes becomes more pronounced. The drive toward sustainable solutions will undoubtedly shape the future of volute design, calling for continuous innovation and adoption of cutting-edge materials and computational methodologies. In summary, the intricacies of pump volute design encapsulate a blend of experience, expertise, authority, and trust, forming the backbone of efficient fluid dynamics across varied industries. As technology advances and the demands for higher efficiency and sustainability grow, an informed approach to volute design and material selection will remain indispensable. Mastery of these elements not only affirms an organization's commitment to innovation but also solidifies its reputation as a leader in the dynamic world of fluid mechanics.

Trust in pump volute design and manufacturing is cemented by rigorous standards and certifications. Organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) set benchmarks for design, safety, and performance. Ensuring compliance with these standards not only showcases a company's commitment to quality but also ensures clients receive products that meet or exceed regulatory expectations. Moreover, real-world case studies highlight the transformative impact of optimized volute designs. Consider an industrial wastewater treatment plant that, by upgrading to volutes tailored to handle high-viscosity slurries, saw a 25% boost in pump efficiency. This case exemplified the practical benefits of computational advancements and material improvements, underscoring the need for comprehensive expertise in selecting and designing volutes suitable for specific applications. The ongoing evolution of pump volute technology is a testament to the demand for improved energy efficiency and reduced ecological footprints. As industries strive to lower energy consumption and emissions, the role of efficiently designed volutes becomes more pronounced. The drive toward sustainable solutions will undoubtedly shape the future of volute design, calling for continuous innovation and adoption of cutting-edge materials and computational methodologies. In summary, the intricacies of pump volute design encapsulate a blend of experience, expertise, authority, and trust, forming the backbone of efficient fluid dynamics across varied industries. As technology advances and the demands for higher efficiency and sustainability grow, an informed approach to volute design and material selection will remain indispensable. Mastery of these elements not only affirms an organization's commitment to innovation but also solidifies its reputation as a leader in the dynamic world of fluid mechanics.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024