-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

slurry pump rebuild

Rebuilding Slurry Pumps A Comprehensive Guide

Slurry pumps are essential equipment in various industries, including mining, construction, and wastewater treatment. These pumps are designed to handle abrasive and viscous fluids, making them integral in transporting materials like sludge, silt, and other mixtures. However, like any mechanical equipment, slurry pumps endure wear and tear over time, necessitating periodic maintenance and rebuilding. This article explores the process, benefits, and considerations for rebuilding slurry pumps.

Understanding Slurry Pumps

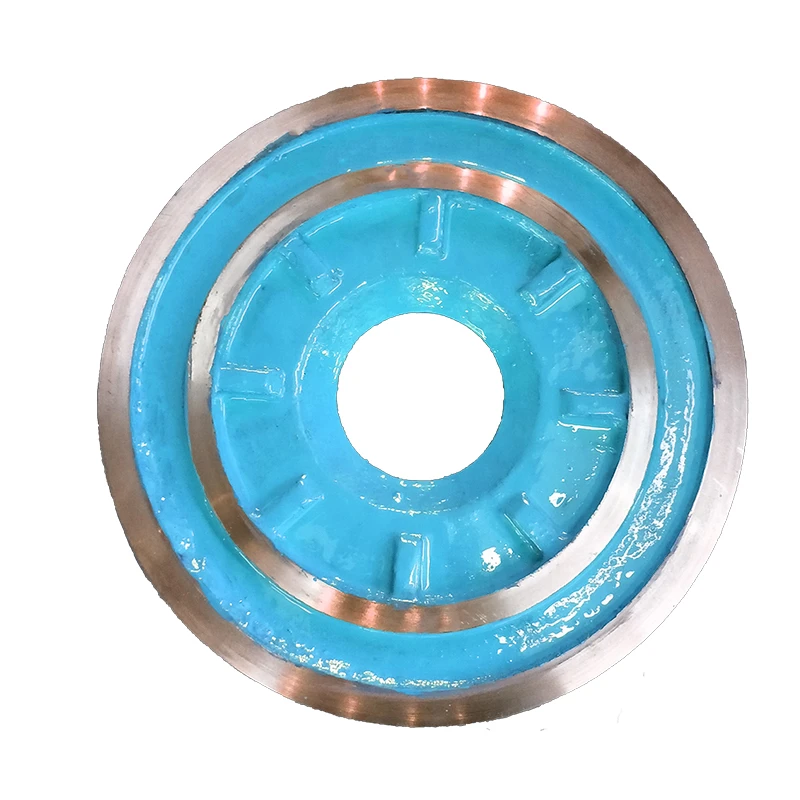

Slurry pumps are specialized centrifugal pumps designed to move mixtures of liquid and solid particles. The pump's construction typically features robust materials to withstand the harsh conditions of slurry transport, including abrasion and corrosion. The primary components of a slurry pump include the casing, impeller, shaft, and liner. Since these components are subject to significant wear, regular inspections and rebuilding are crucial for prolonged performance.

Signs Your Slurry Pump Needs Rebuilding

To ensure optimal performance, operators must recognize the signs that a slurry pump needs rebuilding

. Common indicators include1. Reduced Efficiency A noticeable drop in pumping efficiency can signal wear in the impeller or casing. 2. Vibrations Excessive vibrations can indicate misalignment or wear in the bearings, which can lead to pump failure if not addressed. 3. Leakage Seepage of slurry around the casing or seals often suggests that components are worn or damaged. 4. Unusual Noises Grinding or rattling sounds during operation can point to mechanical failures or issues within the pump.

The Rebuilding Process

Rebuilding a slurry pump involves several key steps to restore its functionality and efficiency

1. Disassembly Begin by safely shutting down and isolating the pump from the system. Carefully disassemble the pump, taking note of the arrangement and condition of each component. 2. Inspection Thoroughly inspect all parts for signs of wear, corrosion, or damage. Pay close attention to the impeller, casing, and any seals or bearings. Determine which components can be repaired, which need replacing, and which can be reused.

slurry pump rebuild

3. Cleaning Clean all components to remove any accumulated slurry, debris, or deposits. Proper cleaning is crucial for ensuring that any wear is accurately assessed and to prevent contamination in the rebuilt unit.

4. Replacement of Components Replace any damaged or worn parts with original or compatible components. This could include new impellers, casings, liners, and seals that are specifically designed for handling abrasive materials.

5. Reassembly Carefully reassemble the pump, ensuring that all components are correctly aligned and secured. Pay particular attention to sealing surfaces to prevent future leaks.

6. Testing Once reassembled, the pump should undergo testing to ensure it operates efficiently and effectively. Monitor for vibrations, noise, and any signs of leakage during this phase.

Benefits of Rebuilding Slurry Pumps

Rebuilding slurry pumps offers several advantages

- Cost-Effective Rebuilding is often less expensive than purchasing a new pump, providing significant cost savings while restoring performance. - Extended Life Properly rebuilt pumps can operate efficiently for years, extending their lifespan and improving return on investment. - Reduced Downtime In many cases, rebuilding can be completed faster than sourcing a new pump, minimizing production disruptions.

Conclusion

Rebuilding slurry pumps is a crucial aspect of maintenance that ensures uninterrupted operations in environments where these pumps are vital. By understanding the signs of wear, following a systematic rebuilding process, and recognizing the benefits of this approach, operators can maintain their equipment effectively. With proper care, rebuilt slurry pumps can continue to deliver excellent performance, ensuring productivity and reliability in challenging conditions.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024