-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

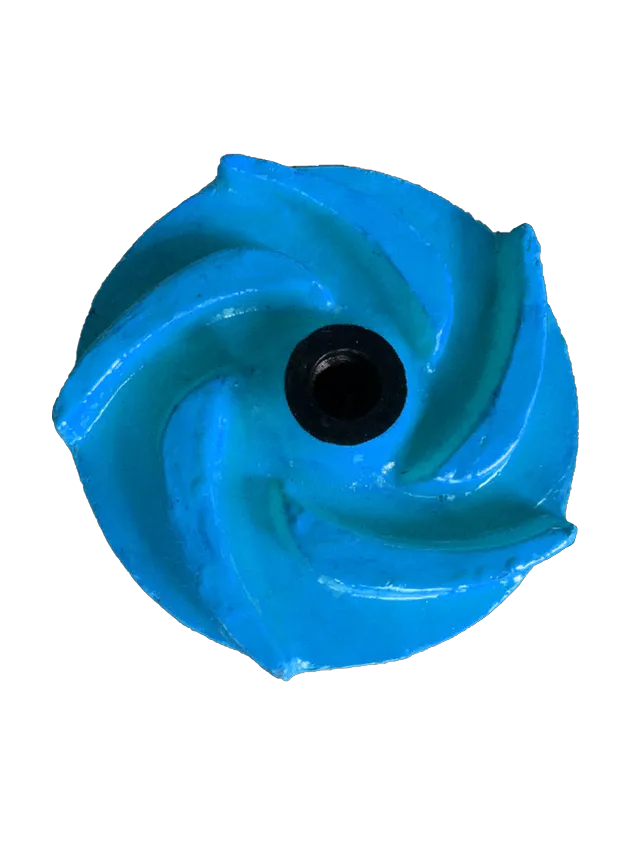

metallic volute pump

The Evolution and Importance of Metallic Volute Pumps

In modern engineering and fluid dynamics, the role of pumps cannot be overstated. Among the multitude of designs, the metallic volute pump stands out due to its intricate design, efficient performance, and suitability for a wide array of applications. This article delves into the features, advantages, and applications of metallic volute pumps, reflecting on their significance in various industries.

Understanding the Metallic Volute Pump

A metallic volute pump is characterized by its spiral-shaped casing—a volute—that surrounds the impeller. This design is crucial for the efficient conversion of kinetic energy imparted by the impeller into pressure energy. The volute is designed to gradually increase in diameter to allow the fluid to flow out smoothly. The use of metallic materials, such as cast iron, stainless steel, or special alloys, provides robustness and longevity, crucial for handling various fluids in diverse environments.

Key Features of Metallic Volute Pumps

One of the defining features of metallic volute pumps is their high efficiency

. The volute design minimizes turbulence, allowing for smooth fluid flow and reduced hydraulic losses. This efficiency is particularly beneficial when pumping viscous or abrasive fluids, which can otherwise cause significant wear in less robust designs.Another feature is the durability of metallic construction. Metallic volute pumps can withstand a variety of environmental conditions, including extreme temperatures, pressures, and corrosive materials. This durability makes them suitable for industrial applications such as chemical processing, water treatment, and oil and gas exploration.

Moreover, these pumps can be customized based on the specific needs of the application. The impeller size, volute shape, and material choices can be tailored to enhance performance according to the particular fluid characteristics and environmental conditions.

Advantages of Using Metallic Volute Pumps

The advantages of metallic volute pumps extend beyond their design features. First and foremost is their reliability. Built to endure harsh conditions, these pumps have a longer lifespan compared to non-metallic alternatives, leading to reduced maintenance costs and downtime.

metallic volute pump

Energy efficiency is another critical advantage. The optimized volute design facilitates an effective fluid transfer, meaning less energy is wasted in turbulence and friction. This translates not only to cost savings in energy consumption but also to a lower environmental impact, as less energy usage contributes to reduced carbon emissions.

Safety is a paramount concern in any industrial setting. Metallic volute pumps, due to their sturdy construction, are less likely to fail under pressure. This reliability is particularly crucial when handling hazardous or toxic fluids, where failure could lead to catastrophic consequences.

Applications in Various Industries

Metallic volute pumps are used across various sectors, each benefitting from the unique advantages these pumps offer. In the oil and gas industry, they are essential for transporting crude oil, natural gas, and other substances through pipelines. Their ability to handle viscous fluids with high efficiency is invaluable in this sector.

In the chemical processing industry, these pumps are instrumental in moving corrosive or reactive fluids. The robustness of metallic materials ensures that the pumps can handle aggressive chemicals without compromising safety.

Moreover, in municipal water treatment facilities, metallic volute pumps are vital in the transport and distribution of water. Their reliability ensures that systems operate smoothly and efficiently, providing a critical resource to communities.

The metal volute pump also finds its applications in power generation, where they transport cooling water and other essential fluids, ensuring that systems run efficiently to fulfill energy demands.

Conclusion

In conclusion, metallic volute pumps play a crucial role in various industrial processes, thanks to their efficient design, durability, and versatility. As industries continue to evolve and demand greater efficiency and reliability, the significance of these pumps is expected to grow. Understanding their features and benefits will help engineers and decision-makers choose the right pump for their specific applications, ensuring sustainability and efficiency in fluid management systems for years to come.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024