-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 22, 2025 04:49

Back to list

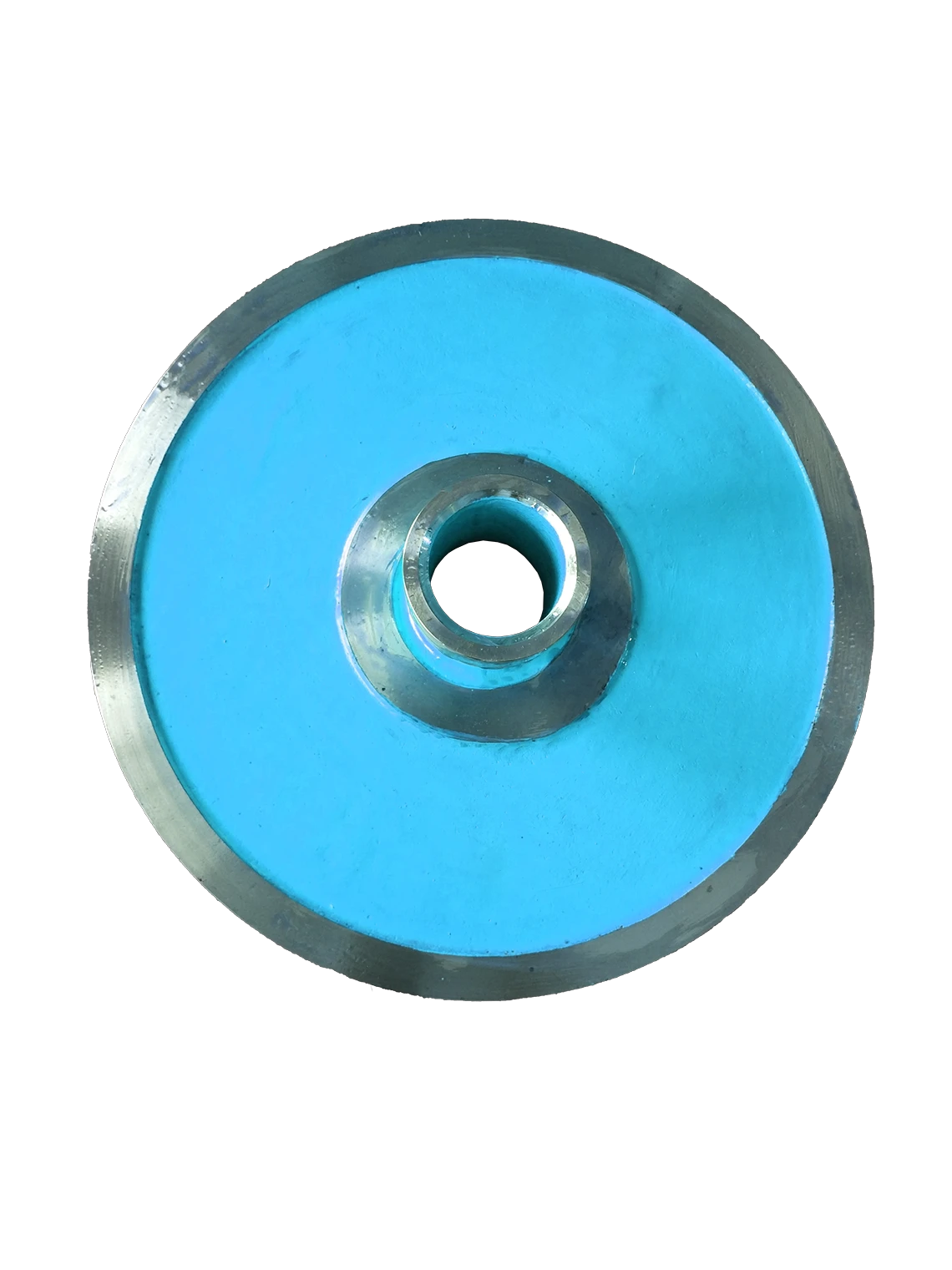

slurry pump bearing assembly

Optimizing the performance and longevity of slurry pump bearing assembly is critical in industries where handling abrasive and corrosive fluids is routine. In mining, wastewater management, and mineral processing, the efficiency and reliability of slurry pumps depend significantly on the robustness of their bearing assemblies. Having dealt with various slurry pump systems, it's clear that knowledge and expertise make all the difference in achieving optimized performance.

The authoritativeness of information surrounding slurry pump bearing assemblies can be gleaned from collaborations with industry leaders and continuous research developments. Esteemed organizations often publish findings showcasing innovations in bearing materials and designs. These authoritative sources ensure that the latest technological advancements are utilized to improve pump performance and reliability. Leveraging partnerships with leading manufacturers often leads to enhancements in bearing design and material selection, thereby ensuring the equipment operates at peak efficiency. Trustworthiness in handling slurry pump systems stems from a transparent approach to problem-solving and solution development. Providing clients with detailed documentation and data-driven assessments allows for informed decision-making. It's essential for professionals in the field to maintain open communication channels with customers, offering scalable solutions that are backed by empirical evidence and case studies. Educating end-users on the operational intricacies and potential pitfalls of slurry pump bearing assemblies fosters a culture of trust and reliability. In conclusion, the success and efficiency of slurry pump operations heavily rely on the expert management of their bearing assemblies. Through a balanced blend of experience, expertise, authority, and trust, organizations can significantly enhance the performance of their slurry pump systems, leading to operational excellence and reduced costs.

The authoritativeness of information surrounding slurry pump bearing assemblies can be gleaned from collaborations with industry leaders and continuous research developments. Esteemed organizations often publish findings showcasing innovations in bearing materials and designs. These authoritative sources ensure that the latest technological advancements are utilized to improve pump performance and reliability. Leveraging partnerships with leading manufacturers often leads to enhancements in bearing design and material selection, thereby ensuring the equipment operates at peak efficiency. Trustworthiness in handling slurry pump systems stems from a transparent approach to problem-solving and solution development. Providing clients with detailed documentation and data-driven assessments allows for informed decision-making. It's essential for professionals in the field to maintain open communication channels with customers, offering scalable solutions that are backed by empirical evidence and case studies. Educating end-users on the operational intricacies and potential pitfalls of slurry pump bearing assemblies fosters a culture of trust and reliability. In conclusion, the success and efficiency of slurry pump operations heavily rely on the expert management of their bearing assemblies. Through a balanced blend of experience, expertise, authority, and trust, organizations can significantly enhance the performance of their slurry pump systems, leading to operational excellence and reduced costs.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024