-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 22, 2025 04:27

Back to list

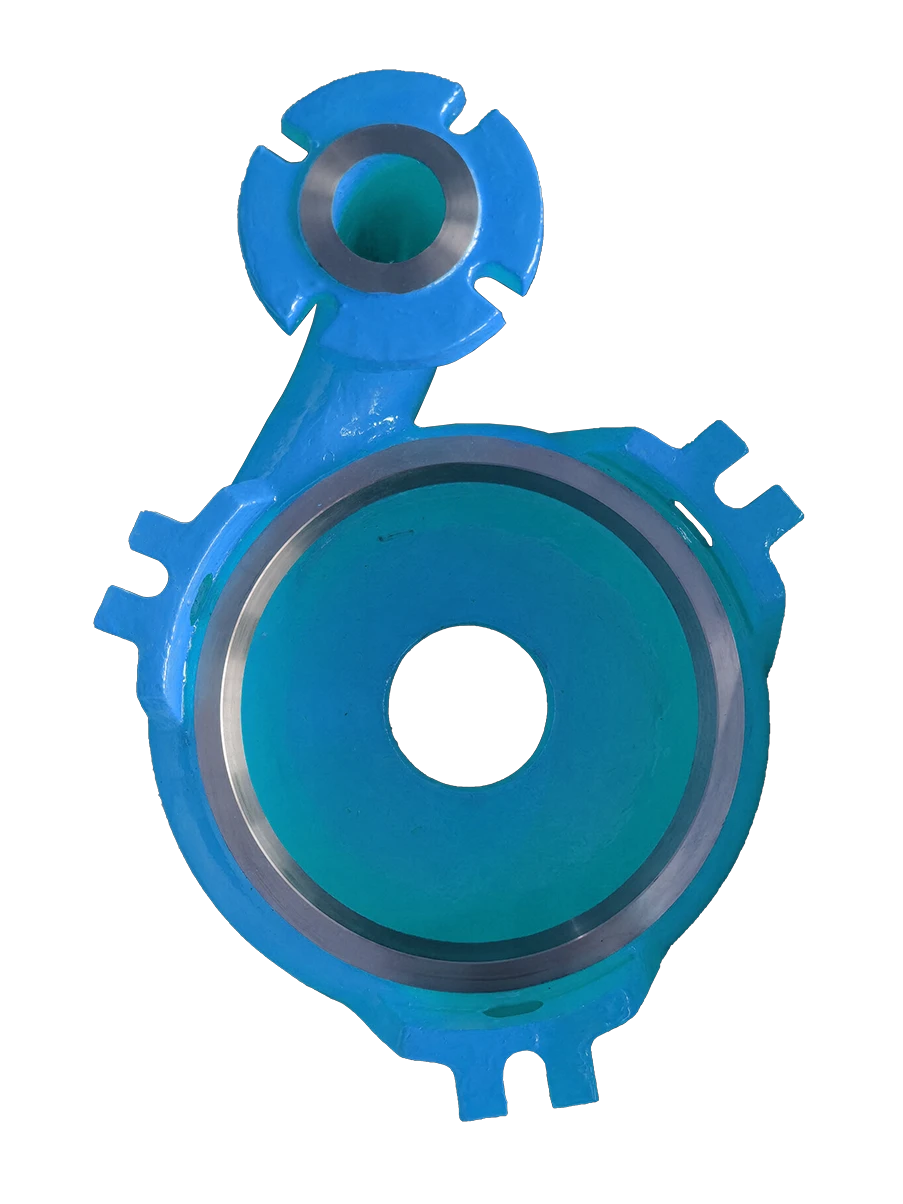

slurry pump assembly

Slurry pumps are integral components of a variety of industrial applications, particularly in mining, construction, and wastewater management. An effective slurry pump assembly can significantly enhance operational efficiency by ensuring that solid-liquid mixtures are transported seamlessly, thus reducing downtime and maintenance costs. Understanding the ins and outs of slurry pump assemblies can empower plant managers and engineers to make informed decisions and optimize their systems for superior performance.

A common challenge in handling slurry pumps is dealing with cavitation, a phenomenon where vapor bubbles form and collapse, potentially causing severe damage. Designing pump and suction systems to maintain consistent pressure and minimize turbulence is critical. Adding an anti-cavitation device or utilizing variable speed drives can optimize pump performance, underlining the industry expertise needed to manage such complex tasks. To maximize the effectiveness of slurry pump assemblies, customization often provides the best solution. Every industry presents unique challenges whether it is temperature, pressure, or chemical composition. Collaborating with manufacturers that offer bespoke services can vastly improve the assembly's fit for purpose. This reinforces the necessity for operators to work closely with highly regarded professionals who understand the nuances of slurry pumping. Safety is non-negotiable when it comes to slurry pump assembly. Training and adherence to best practices in operation and maintenance safeguard not only personnel but also the environmental systems around them. Professional development programs that focus on slurry dynamics and equipment handling build a culture of safety and trust among teams. In conclusion, optimizing a slurry pump assembly requires a blend of real-world experience, technical prowess, authoritative guidance, and an unwavering commitment to trust-building practices. By integrating these elements, industries can achieve enhanced efficiency, reduced downtime, and a robust system capable of facing the gritty challenges of modern production demands. Whether you’re planning upgrades or daily maintenance, leveraging the accumulated expertise from trusted sources ensures that your slurry pump assembly stands resilient against the test of time.

A common challenge in handling slurry pumps is dealing with cavitation, a phenomenon where vapor bubbles form and collapse, potentially causing severe damage. Designing pump and suction systems to maintain consistent pressure and minimize turbulence is critical. Adding an anti-cavitation device or utilizing variable speed drives can optimize pump performance, underlining the industry expertise needed to manage such complex tasks. To maximize the effectiveness of slurry pump assemblies, customization often provides the best solution. Every industry presents unique challenges whether it is temperature, pressure, or chemical composition. Collaborating with manufacturers that offer bespoke services can vastly improve the assembly's fit for purpose. This reinforces the necessity for operators to work closely with highly regarded professionals who understand the nuances of slurry pumping. Safety is non-negotiable when it comes to slurry pump assembly. Training and adherence to best practices in operation and maintenance safeguard not only personnel but also the environmental systems around them. Professional development programs that focus on slurry dynamics and equipment handling build a culture of safety and trust among teams. In conclusion, optimizing a slurry pump assembly requires a blend of real-world experience, technical prowess, authoritative guidance, and an unwavering commitment to trust-building practices. By integrating these elements, industries can achieve enhanced efficiency, reduced downtime, and a robust system capable of facing the gritty challenges of modern production demands. Whether you’re planning upgrades or daily maintenance, leveraging the accumulated expertise from trusted sources ensures that your slurry pump assembly stands resilient against the test of time.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024