-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 07:07

Back to list

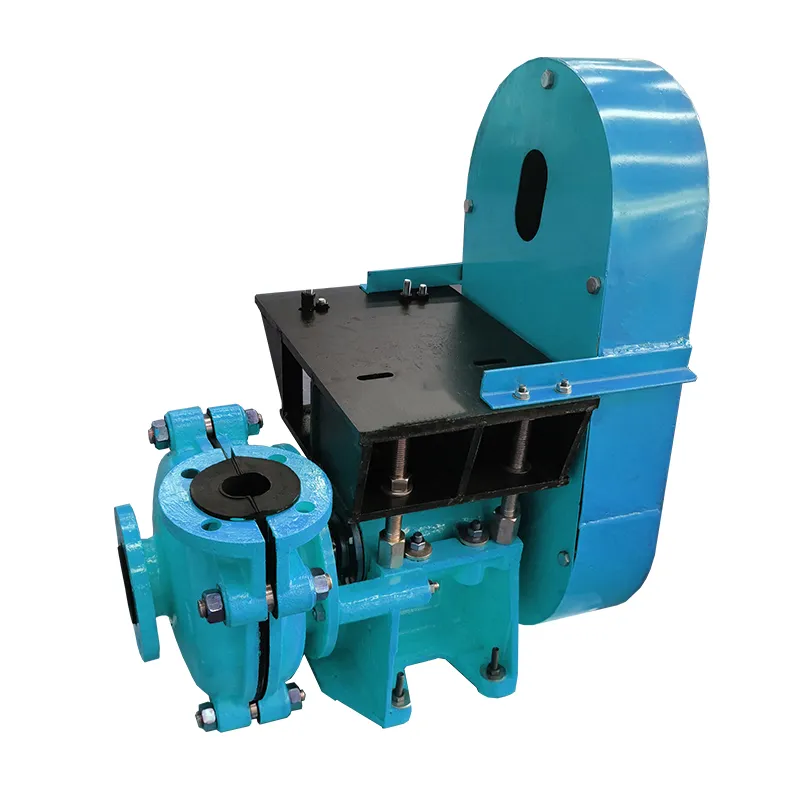

slurry agitator

In the realm of industrial processing, the slurry agitator stands as a quintessential element, ensuring efficiency, consistency, and optimal throughput across various sectors. Its primary role is to homogenize liquid and solid materials, facilitating the smooth operation of processes where uniform consistency is invaluable. Despite its critical function, the intricacies and nuances of slurry agitators are often underestimated, leading to inefficiencies and avoidable maintenance issues in operations.

Over recent years, technological advancements have refined slurry agitators, enhancing their performance and applicability. Innovations such as variable frequency drives (VFDs) afford operators unparalleled control over agitation speeds, which can be adjusted in real-time to accommodate changing slurry conditions and process demands. Furthermore, the integration of digital monitoring systems and smart sensors facilitates precise data collection and analysis, allowing for the predictive maintenance of equipment. This revolution in data management not only boosts operational efficiency but also contributes to significant reductions in energy consumption and operational costs. The correct implementation of a slurry agitator is not only dependent on the physical characteristics and technology but is also significantly influenced by regulatory and environmental considerations. Industry standards dictate specific safety checks, ensuring that operations do not compromise worker safety or environmental integrity. Compliance with such standards necessitates the incorporation of safety features such as automatic shut-off systems, containment measures, and fail-safes that are activated upon the detection of anomalies. In conclusion, a comprehensive understanding of slurry agitators, reinforced by real-world experience and continual advancements in technology, positions industries to maximize their profitability through enhanced processing efficiencies. The symbiotic relationship between reliable equipment design and state-of-the-art technology ensures slurry agitators remain indispensable in modern industrial practices. As industries evolve, so will the technologies underpinning these crucial devices—paving the way for more innovative solutions to complex mixing challenges.

Over recent years, technological advancements have refined slurry agitators, enhancing their performance and applicability. Innovations such as variable frequency drives (VFDs) afford operators unparalleled control over agitation speeds, which can be adjusted in real-time to accommodate changing slurry conditions and process demands. Furthermore, the integration of digital monitoring systems and smart sensors facilitates precise data collection and analysis, allowing for the predictive maintenance of equipment. This revolution in data management not only boosts operational efficiency but also contributes to significant reductions in energy consumption and operational costs. The correct implementation of a slurry agitator is not only dependent on the physical characteristics and technology but is also significantly influenced by regulatory and environmental considerations. Industry standards dictate specific safety checks, ensuring that operations do not compromise worker safety or environmental integrity. Compliance with such standards necessitates the incorporation of safety features such as automatic shut-off systems, containment measures, and fail-safes that are activated upon the detection of anomalies. In conclusion, a comprehensive understanding of slurry agitators, reinforced by real-world experience and continual advancements in technology, positions industries to maximize their profitability through enhanced processing efficiencies. The symbiotic relationship between reliable equipment design and state-of-the-art technology ensures slurry agitators remain indispensable in modern industrial practices. As industries evolve, so will the technologies underpinning these crucial devices—paving the way for more innovative solutions to complex mixing challenges.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024