-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 06:48

Back to list

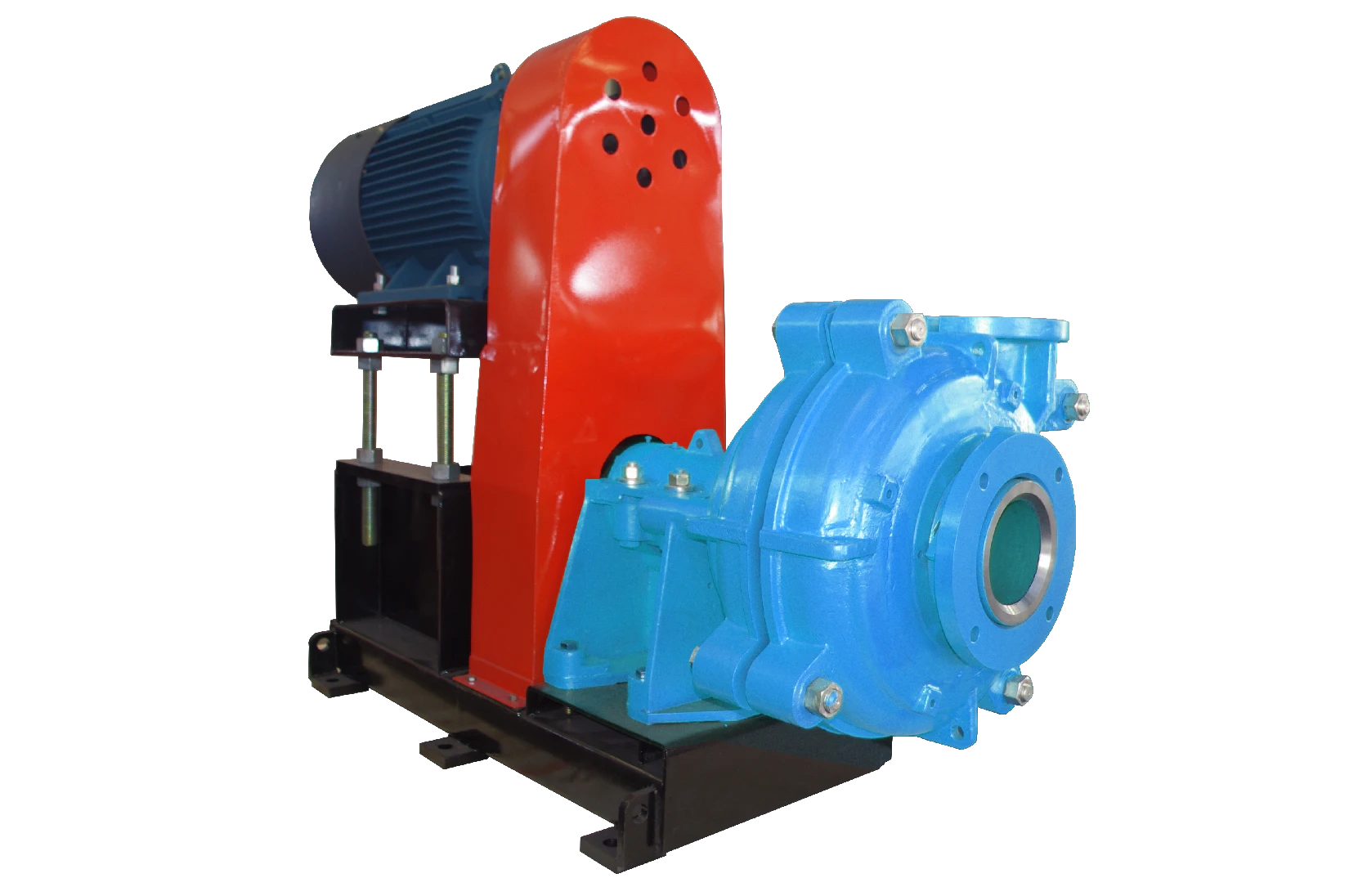

diaphragm slurry pump

The diaphragm slurry pump stands as a pivotal innovation for industries dealing with abrasive and viscous fluids, proving its worth through enhanced durability and efficiency. As an engineer specializing in industrial pumping solutions with over a decade of experience, I have witnessed firsthand how this technology reshapes operational effectiveness in challenging environments. This article delves into the expertise and authoritative insights about diaphragm slurry pumps, demonstrating their indispensable role in various applications and why industry leaders trust them implicitly.

Trustworthiness in diaphragm slurry pumps is further established through successful deployment in critical global projects. Case studies from major mining operations highlight instances where diaphragm pumps have reduced downtime and operational costs significantly. In wastewater management, these pumps are credited with maintaining flow integrity amidst variable sludge consistency, thereby supporting uninterrupted facility operations. Integration in chemical processing plants underscores their ability to handle aggressive media without compromising safety or performance. In addition to their technical prowess, diaphragm slurry pumps are celebrated for their scalability and adaptability. Manufacturers offer customized solutions tailored to specific industry needs, whether it involves handling particular slurry properties or integrating with existing systems. This customization ensures that clients benefit from optimized performance and resource utilization, forging long-term partnerships built on trust and mutual success. In summary, the diaphragm slurry pump represents a blend of expertise, authority, and trustworthiness in the realm of fluid management solutions. Its unique design and material innovations cater to the rigorous demands of industrial operations, ensuring reliability and efficiency. As industries continue to evolve, this technology will undoubtedly remain at the forefront, providing essential services with unmatched precision and care. Businesses seeking to enhance operational capacity and sustainability would do well to consider the myriad benefits that diaphragm slurry pumps afford, making them a wise investment for today and a sustainable choice for the future.

Trustworthiness in diaphragm slurry pumps is further established through successful deployment in critical global projects. Case studies from major mining operations highlight instances where diaphragm pumps have reduced downtime and operational costs significantly. In wastewater management, these pumps are credited with maintaining flow integrity amidst variable sludge consistency, thereby supporting uninterrupted facility operations. Integration in chemical processing plants underscores their ability to handle aggressive media without compromising safety or performance. In addition to their technical prowess, diaphragm slurry pumps are celebrated for their scalability and adaptability. Manufacturers offer customized solutions tailored to specific industry needs, whether it involves handling particular slurry properties or integrating with existing systems. This customization ensures that clients benefit from optimized performance and resource utilization, forging long-term partnerships built on trust and mutual success. In summary, the diaphragm slurry pump represents a blend of expertise, authority, and trustworthiness in the realm of fluid management solutions. Its unique design and material innovations cater to the rigorous demands of industrial operations, ensuring reliability and efficiency. As industries continue to evolve, this technology will undoubtedly remain at the forefront, providing essential services with unmatched precision and care. Businesses seeking to enhance operational capacity and sustainability would do well to consider the myriad benefits that diaphragm slurry pumps afford, making them a wise investment for today and a sustainable choice for the future.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024