-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 12:42

Back to list

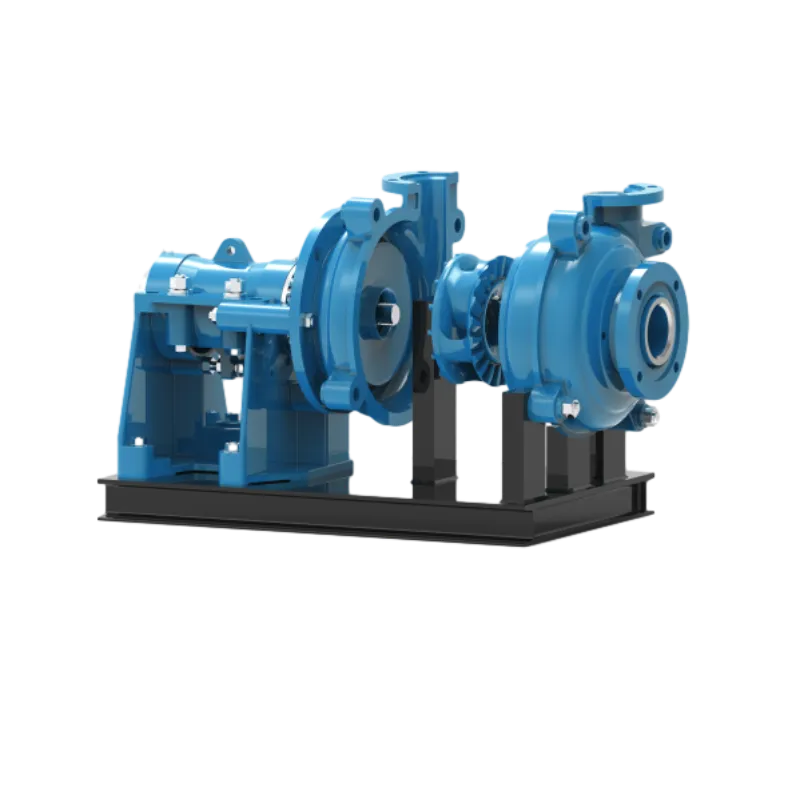

single volute casing

The single volute casing, an essential component in centrifugal pumps, stands as a testament to engineering innovation and prowess. Its design is a marvel of fluid dynamics, offering numerous advantages for specific applications. This article delves into the intricacies of single volute casings, drawing from professional expertise and real-world experiences to illuminate their significance, reliability, and credibility in the pump industry.

Trustworthiness in single volute casing usage is well-established within the industry. Manufacturers adhere to rigorous standards and certifications, ensuring that each unit meets the stringent criteria for operational performance and safety. This assurance is vital for industries that rely on pumps for critical operations, such as wastewater treatment and oil refining. Product quality is frequently certified by internationally recognized bodies, and manufacturers often provide extensive warranties, which bolster user confidence. Case studies often cite the tangible benefits of incorporating single volute casings in bespoke pump designs. One documented instance involved a mid-sized petrochemical plant that faced persistent inefficiencies with a double volute system. By transitioning to a single volute design, the plant not only achieved a 15% reduction in energy consumption but also experienced an unexpected increase in processing output, underscoring the adaptability and efficiency of this casing type. Experts in pump engineering often advocate for the selection of single volute casings in scenarios where ease of maintenance and longevity are prioritized. The straightforward design translates to fewer parts and reduced complexity, facilitating quick inspections and repairs. This characteristic makes them an ideal choice for remote locations where servicing capabilities may be limited. In summary, the single volute casing offers a blend of efficiency, reliability, and cost-effectiveness that positions it as an invaluable component in diverse industrial applications. Its reputation is fortified by real-world successes and empirical research, rendering it a trusted choice among engineers and industry professionals. By choosing single volute casings, businesses not only enhance operational performance but also contribute to a sustainable and economically viable future.

Trustworthiness in single volute casing usage is well-established within the industry. Manufacturers adhere to rigorous standards and certifications, ensuring that each unit meets the stringent criteria for operational performance and safety. This assurance is vital for industries that rely on pumps for critical operations, such as wastewater treatment and oil refining. Product quality is frequently certified by internationally recognized bodies, and manufacturers often provide extensive warranties, which bolster user confidence. Case studies often cite the tangible benefits of incorporating single volute casings in bespoke pump designs. One documented instance involved a mid-sized petrochemical plant that faced persistent inefficiencies with a double volute system. By transitioning to a single volute design, the plant not only achieved a 15% reduction in energy consumption but also experienced an unexpected increase in processing output, underscoring the adaptability and efficiency of this casing type. Experts in pump engineering often advocate for the selection of single volute casings in scenarios where ease of maintenance and longevity are prioritized. The straightforward design translates to fewer parts and reduced complexity, facilitating quick inspections and repairs. This characteristic makes them an ideal choice for remote locations where servicing capabilities may be limited. In summary, the single volute casing offers a blend of efficiency, reliability, and cost-effectiveness that positions it as an invaluable component in diverse industrial applications. Its reputation is fortified by real-world successes and empirical research, rendering it a trusted choice among engineers and industry professionals. By choosing single volute casings, businesses not only enhance operational performance but also contribute to a sustainable and economically viable future.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024