-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 12:19

Back to list

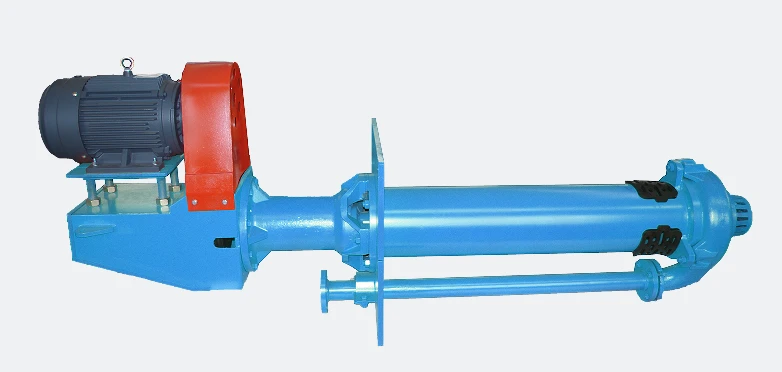

metallic volute pumps

The realm of industrial fluid management is increasingly reliant on innovative technology to optimize efficiency and performance. Among the standout components in this sector are metallic volute pumps. These devices not only serve a vast array of industrial applications but also provide a benchmark for engineering excellence and operational reliability.

Experts in fluid dynamics further commend metallic volute pumps for their adaptability. The engineering behind these pumps allows them to be customized to meet specific industrial needs. Variables such as flow rate, pressure capacity, and the fluid's physical properties are meticulously accounted for in each pump's design and manufacturing process. This adaptability ensures that the pumps not only meet industry standards but often surpass them. Manufacturers of these pumps also ensure regulatory compliance with a host of international standards. By adhering to ISO and other regional certifications, these devices are positioned as credible and authoritative selections for industrial use. This commitment to quality extends to the strategic partnerships and collaborations with engineering and industrial bodies worldwide, contributing to the continuous evolution in the design and functionality of metallic volute pumps. End-users of these pumps testify to the profound impact on their processes, praising their durability and consistent performance. Case studies highlight significant reductions in operating costs and improvements in production efficiency, supported by reliable pump operation over extended periods. Such real-world experiences not only validate the theoretical benefits of metallic volute pumps but also solidify their reputation in commercial settings. Additionally, the ease of maintenance and availability of spare parts further augment the appeal of these pumps. Engineers can swiftly conduct routine inspections and repairs, ensuring minimal disruption to operations. The established network of suppliers and service providers ensures that technical support and parts are readily available, further emphasizing the pumps’ reliability and proving advantageous for cost-effective lifetime management. In summation, metallic volute pumps represent a pinnacle of engineering innovation in the industrial sector. Their design and functionality cater to a diverse range of applications, ensuring efficient, safe, and reliable fluid management. This makes them an indispensable asset to any industry reliant on premium fluid handling solutions, validating their status as a trusted and authoritative choice in the world of industrial machinery.

Experts in fluid dynamics further commend metallic volute pumps for their adaptability. The engineering behind these pumps allows them to be customized to meet specific industrial needs. Variables such as flow rate, pressure capacity, and the fluid's physical properties are meticulously accounted for in each pump's design and manufacturing process. This adaptability ensures that the pumps not only meet industry standards but often surpass them. Manufacturers of these pumps also ensure regulatory compliance with a host of international standards. By adhering to ISO and other regional certifications, these devices are positioned as credible and authoritative selections for industrial use. This commitment to quality extends to the strategic partnerships and collaborations with engineering and industrial bodies worldwide, contributing to the continuous evolution in the design and functionality of metallic volute pumps. End-users of these pumps testify to the profound impact on their processes, praising their durability and consistent performance. Case studies highlight significant reductions in operating costs and improvements in production efficiency, supported by reliable pump operation over extended periods. Such real-world experiences not only validate the theoretical benefits of metallic volute pumps but also solidify their reputation in commercial settings. Additionally, the ease of maintenance and availability of spare parts further augment the appeal of these pumps. Engineers can swiftly conduct routine inspections and repairs, ensuring minimal disruption to operations. The established network of suppliers and service providers ensures that technical support and parts are readily available, further emphasizing the pumps’ reliability and proving advantageous for cost-effective lifetime management. In summation, metallic volute pumps represent a pinnacle of engineering innovation in the industrial sector. Their design and functionality cater to a diverse range of applications, ensuring efficient, safe, and reliable fluid management. This makes them an indispensable asset to any industry reliant on premium fluid handling solutions, validating their status as a trusted and authoritative choice in the world of industrial machinery.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024