-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 19, 2025 10:00

Back to list

Pump Wear Parts SPR65206 Rubber

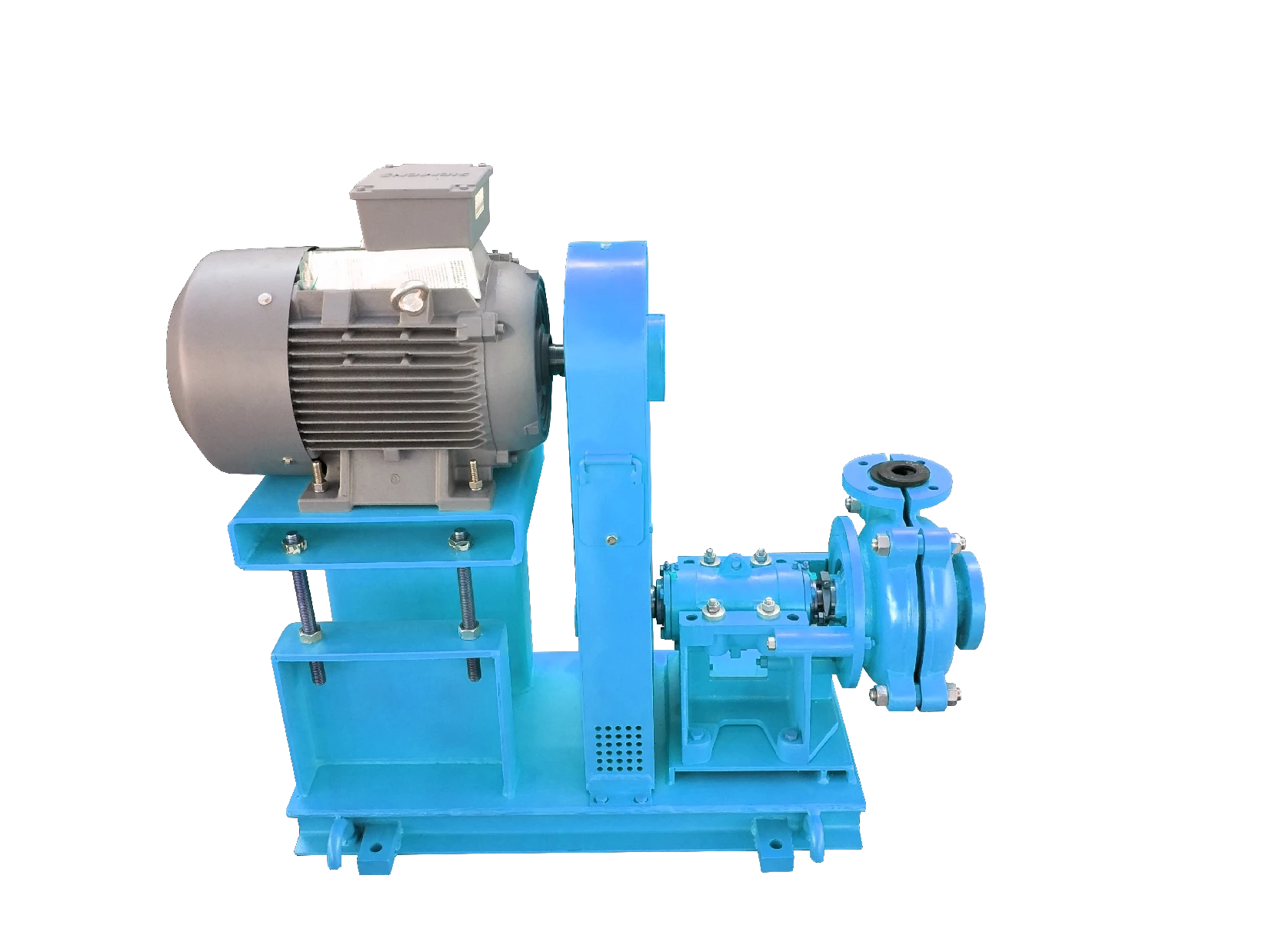

Sewage slurry mud pumps are pivotal in various industries, including wastewater management, mining, and construction. Understanding their unique capabilities, technical aspects, and practical applications can significantly enhance your operations and ensure compliance with environmental standards.

In terms of authoritativeness, numerous case studies have documented the successful deployment of sewage slurry mud pumps in various projects worldwide. For instance, their application in municipal wastewater treatment facilities has been transformative, providing a reliable solution for transporting sludge from anaerobic digesters to dewatering processes. In mining operations, these pumps have proven essential for moving tailings safely and efficiently, highlighting their critical role in resource management and environmental protection. Trustworthiness is established through adherence to quality standards and certifications. Leading manufacturers ensure that their pumps meet stringent international benchmarks such as ISO, ANSI, and CE certifications. These certifications offer peace of mind to operators, guaranteeing that the equipment has been rigorously tested for performance, safety, and environmental compliance. The practical experience of industry professionals further underscores the value of these pumps. Operators who regularly use these pumps report significant time savings and reduced maintenance costs. Innovations such as remote monitoring systems and automated shutdown features have enhanced operational monitoring and maintenance planning, allowing for predictive maintenance and reducing the risk of unexpected failures. In conclusion, the utility of sewage slurry mud pumps in industrial applications is unmatched. They provide sustainability and operational efficiency by effectively managing waste transport and minimizing environmental impact. Investing in high-quality pumps and keeping abreast with technological advancements in the field can lead to improved performance and substantial cost savings in the long term. As industries continue to strive for efficiency and sustainability, sewage slurry mud pumps remain indispensable tools for achieving these goals.

In terms of authoritativeness, numerous case studies have documented the successful deployment of sewage slurry mud pumps in various projects worldwide. For instance, their application in municipal wastewater treatment facilities has been transformative, providing a reliable solution for transporting sludge from anaerobic digesters to dewatering processes. In mining operations, these pumps have proven essential for moving tailings safely and efficiently, highlighting their critical role in resource management and environmental protection. Trustworthiness is established through adherence to quality standards and certifications. Leading manufacturers ensure that their pumps meet stringent international benchmarks such as ISO, ANSI, and CE certifications. These certifications offer peace of mind to operators, guaranteeing that the equipment has been rigorously tested for performance, safety, and environmental compliance. The practical experience of industry professionals further underscores the value of these pumps. Operators who regularly use these pumps report significant time savings and reduced maintenance costs. Innovations such as remote monitoring systems and automated shutdown features have enhanced operational monitoring and maintenance planning, allowing for predictive maintenance and reducing the risk of unexpected failures. In conclusion, the utility of sewage slurry mud pumps in industrial applications is unmatched. They provide sustainability and operational efficiency by effectively managing waste transport and minimizing environmental impact. Investing in high-quality pumps and keeping abreast with technological advancements in the field can lead to improved performance and substantial cost savings in the long term. As industries continue to strive for efficiency and sustainability, sewage slurry mud pumps remain indispensable tools for achieving these goals.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024