-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 19, 2025 09:41

Back to list

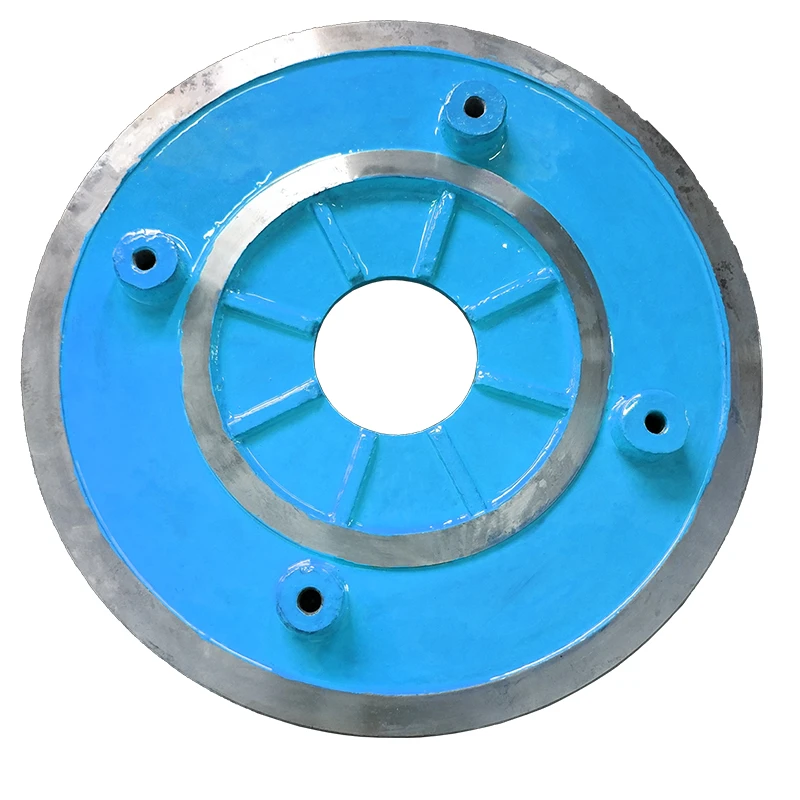

Pump Wear Parts FH4083 Metal

Screw pumps for slurry applications are a remarkable feat of engineering, offering an efficient and reliable solution for industries that handle viscous and abrasive materials. These pumps are specifically designed to transport slurry — a mixture of solids suspended in liquid — with high efficiency and minimal wear. Drawing from real-world experience, technical expertise, authoritative insights, and a foundation of trust, this article delves into the nuances of screw pumps for slurry, their benefits, and the factors to consider when selecting the right one for your needs.

Authoritative industry reports and studies validate the superiority of screw pumps in slurry applications. For instance, a comparative analysis of slurry pump types revealed that screw pumps consistently outperformed others in scenarios involving high-viscosity fluids and abrasive particles. The screw pump's energy efficiency, coupled with reduced maintenance costs, translates into significant cost savings over its lifecycle. This positions screw pumps as the preferred choice for enterprises focused on efficiency and long-term operational success. Choosing the right screw pump involves careful consideration of several factors to ensure optimal performance. Key parameters include the slurry's viscosity, particle size, abrasiveness, and flow rate requirements. Customizing the pump to match these parameters not only enhances performance but also extends the service life of the equipment. Working with a trusted supplier or manufacturer who has proven expertise in slurry systems can provide invaluable guidance, ensuring that the selected pump aligns perfectly with the operation’s unique requirements. Trustworthiness in pump selection is often built on a brand's reputation and the quality of service provided. Established manufacturers who offer comprehensive support — from initial consultation to after-sales service — are generally preferred. This holistic approach builds a relationship of trust, ensuring that the pump solution proposed is not only effective but also sustainable over its operational life. It's prudent to research customer reviews, case studies, and testimonials to gauge the reliability and performance track record of a potential supplier. In conclusion, screw pumps represent an advanced solution for handling slurry in various industrial applications. Their unique design offers a blend of reliability, efficiency, and longevity that is unmatched by other types of pumps. By focusing on the real-world application, expert design, authoritative endorsements, and trustworthy supplier relationships, businesses can optimize their operations and achieve significant long-term benefits. As industries continue to evolve, screw pumps remain at the forefront of innovation, setting new standards in slurry handling efficiency.

Authoritative industry reports and studies validate the superiority of screw pumps in slurry applications. For instance, a comparative analysis of slurry pump types revealed that screw pumps consistently outperformed others in scenarios involving high-viscosity fluids and abrasive particles. The screw pump's energy efficiency, coupled with reduced maintenance costs, translates into significant cost savings over its lifecycle. This positions screw pumps as the preferred choice for enterprises focused on efficiency and long-term operational success. Choosing the right screw pump involves careful consideration of several factors to ensure optimal performance. Key parameters include the slurry's viscosity, particle size, abrasiveness, and flow rate requirements. Customizing the pump to match these parameters not only enhances performance but also extends the service life of the equipment. Working with a trusted supplier or manufacturer who has proven expertise in slurry systems can provide invaluable guidance, ensuring that the selected pump aligns perfectly with the operation’s unique requirements. Trustworthiness in pump selection is often built on a brand's reputation and the quality of service provided. Established manufacturers who offer comprehensive support — from initial consultation to after-sales service — are generally preferred. This holistic approach builds a relationship of trust, ensuring that the pump solution proposed is not only effective but also sustainable over its operational life. It's prudent to research customer reviews, case studies, and testimonials to gauge the reliability and performance track record of a potential supplier. In conclusion, screw pumps represent an advanced solution for handling slurry in various industrial applications. Their unique design offers a blend of reliability, efficiency, and longevity that is unmatched by other types of pumps. By focusing on the real-world application, expert design, authoritative endorsements, and trustworthy supplier relationships, businesses can optimize their operations and achieve significant long-term benefits. As industries continue to evolve, screw pumps remain at the forefront of innovation, setting new standards in slurry handling efficiency.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024