-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 02:08

Back to list

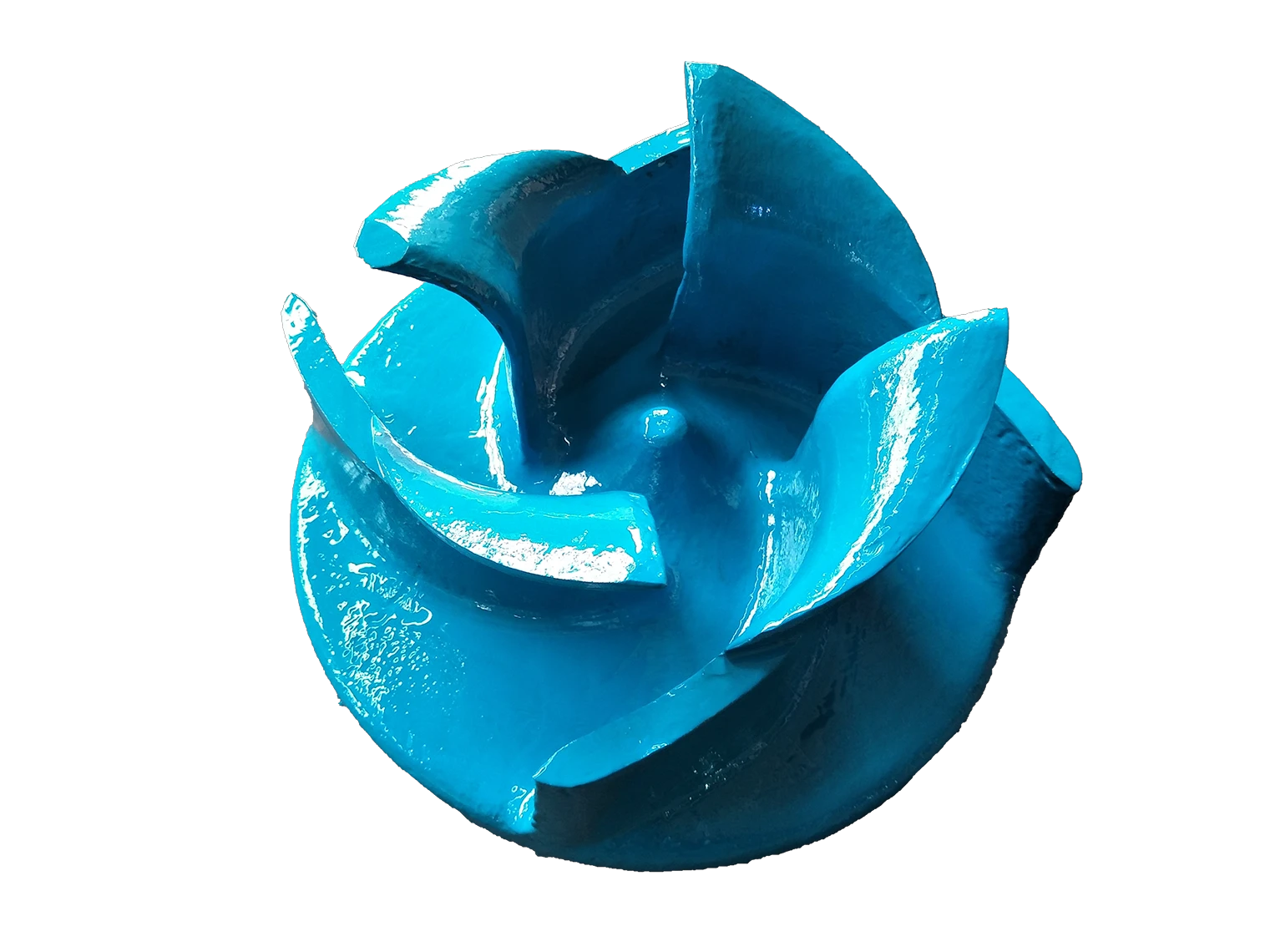

propeller pump is used for

Propeller pumps, an instrumental component in various industrial and agricultural settings, have been gaining traction due to their efficiency and versatility. As industries increasingly lean towards eco-friendly and energy-saving operations, understanding the application and benefits of propeller pumps becomes crucial.

The chemical industry also leverages the capabilities of propeller pumps. In this context, they are primarily used to move corrosive and viscous fluids. The robust design of propeller pumps, often made with materials resistant to chemical wear, makes them reliable for handling such challenging substances. Their consistent flow rate ensures that chemical reactions occur uniformly, reducing the risk of dangerous pressure build-ups or inconsistent product quality. Beyond functionality, the environmental benefits of propeller pumps cannot be overlooked. As companies across the globe strive to meet environmental standards, the demand for energy-efficient pumping solutions rises. Propeller pumps, with their low energy consumption and effective operational capacity, address this need perfectly. They contribute to lowering the carbon footprint of industrial operations, aligning with the global push towards sustainability. One must also consider the longevity and maintenance aspects when discussing propeller pumps. Their straightforward design means fewer mechanical parts are subject to wear and tear, leading to longer operational lifespans and reduced maintenance costs. In industries where downtime equates to significant financial losses, the reliability and easy upkeep of propeller pumps offer a distinct advantage. From an investment standpoint, the adoption of propeller pumps symbolizes a commitment not only to operational efficiency but also to environmental stewardship. They stand as a testament to the progress in industrial design that marries functionality with eco-consciousness, ensuring that industries can thrive while minimizing their ecological impact. In conclusion, propeller pumps are not just a tool for moving liquids; they are an essential part of a modern industrial operation. Their applications span across various sectors, offering unrivaled benefits in terms of efficiency, cost-effectiveness, and sustainability. As the world continues to innovate, propeller pumps remain at the forefront of enhancing the machinery that keeps the wheels of industry turning smoothly.

The chemical industry also leverages the capabilities of propeller pumps. In this context, they are primarily used to move corrosive and viscous fluids. The robust design of propeller pumps, often made with materials resistant to chemical wear, makes them reliable for handling such challenging substances. Their consistent flow rate ensures that chemical reactions occur uniformly, reducing the risk of dangerous pressure build-ups or inconsistent product quality. Beyond functionality, the environmental benefits of propeller pumps cannot be overlooked. As companies across the globe strive to meet environmental standards, the demand for energy-efficient pumping solutions rises. Propeller pumps, with their low energy consumption and effective operational capacity, address this need perfectly. They contribute to lowering the carbon footprint of industrial operations, aligning with the global push towards sustainability. One must also consider the longevity and maintenance aspects when discussing propeller pumps. Their straightforward design means fewer mechanical parts are subject to wear and tear, leading to longer operational lifespans and reduced maintenance costs. In industries where downtime equates to significant financial losses, the reliability and easy upkeep of propeller pumps offer a distinct advantage. From an investment standpoint, the adoption of propeller pumps symbolizes a commitment not only to operational efficiency but also to environmental stewardship. They stand as a testament to the progress in industrial design that marries functionality with eco-consciousness, ensuring that industries can thrive while minimizing their ecological impact. In conclusion, propeller pumps are not just a tool for moving liquids; they are an essential part of a modern industrial operation. Their applications span across various sectors, offering unrivaled benefits in terms of efficiency, cost-effectiveness, and sustainability. As the world continues to innovate, propeller pumps remain at the forefront of enhancing the machinery that keeps the wheels of industry turning smoothly.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024