-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 01:46

Back to list

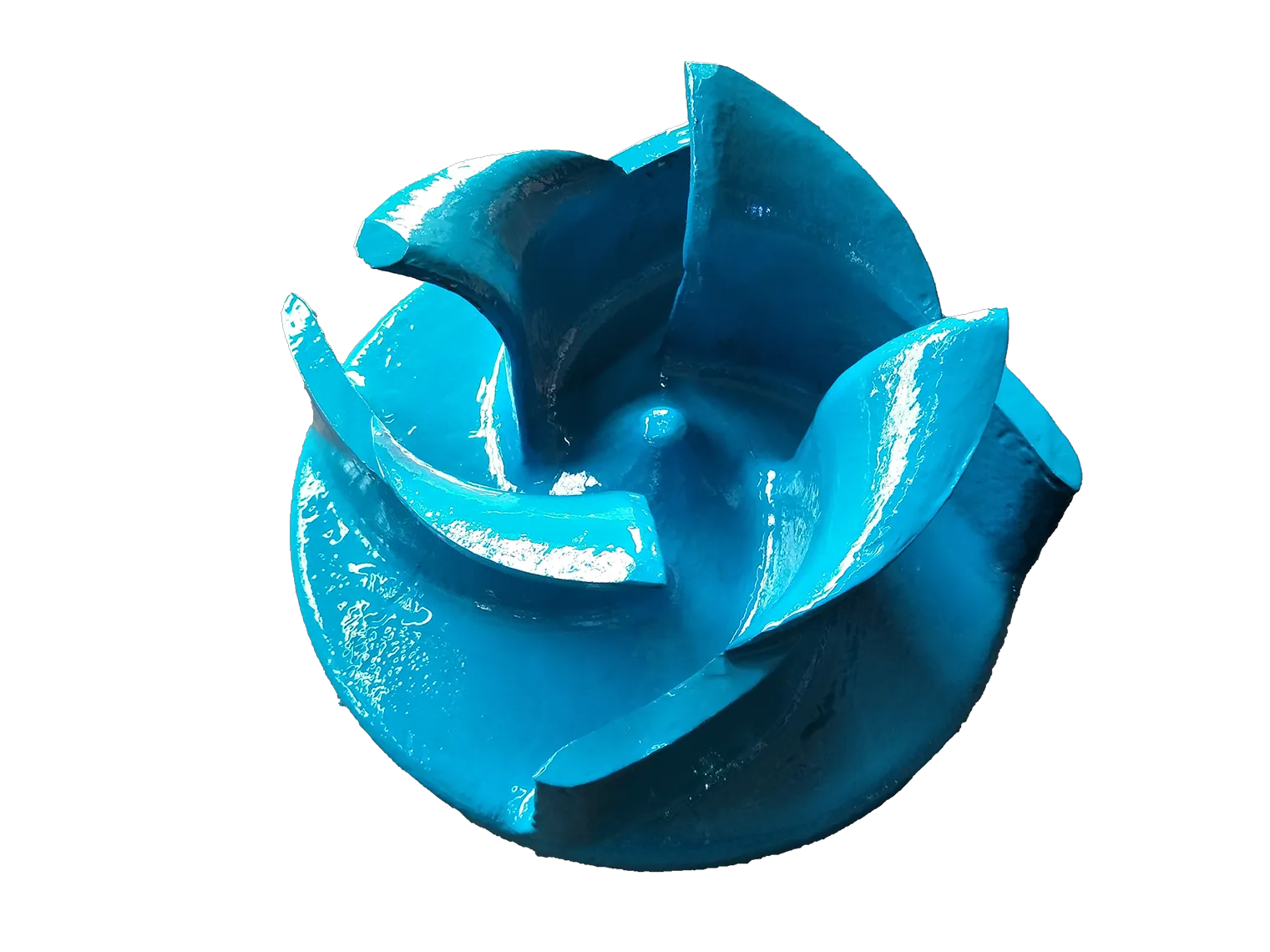

open impeller design

Open impeller design stands as a critical innovation in the realm of fluid dynamics and pump technology, characterized by its ability to handle solid-laden fluids and viscous liquids with enhanced efficiency and reduced clogging. An open impeller design typically consists of vanes attached to a central hub without an enclosing shroud on one or both sides. This straightforward yet highly functional design facilitates a remarkable flow of liquids, even containing significant particulate matter, making it indispensable across numerous industrial applications.

Authoritative case studies affirm the trustworthiness of this design in demanding applications. For example, a leading municipal wastewater treatment plant in the Midwest United States successfully transitioned to open impeller pumps, reporting a notable reduction in maintenance costs and downtime over a five-year period. These practical insights contribute to a broader understanding of how open impellers can improve reliability and performance across similar installations globally. When considering integration with existing systems, the adaptability of open impellers becomes apparent. Retrofit options are available for plants looking to upgrade from traditional impeller designs without extensive system overhauls. Industry articles emphasize the ease of installation and minimal training required for workforce adaptation, thus enhancing the appeal of open impellers to forward-thinking organizations seeking to optimize their operational framework. From a trust perspective, manufacturers and suppliers play a crucial role in endorsing the merits of open impeller designs. By providing comprehensive warranties and responsive support services, they bolster confidence in these solutions. A focus on transparent guidelines and best practices for using, maintaining, and troubleshooting open impeller systems ensures end-users benefit fully from their capabilities. Leading brands continuously invest in research and development, fostering innovation and setting benchmarks that competitors follow, thereby reinforcing the authoritative stature of open impeller technology in the market. In summary, the open impeller design remains an exemplar of engineering excellence, combining practical expertise and theoretical insights to meet the evolving demands of various industries. Its adoption reflects a strategic decision to enhance fluid dynamics efficiency, operational sustainability, and system resilience. As industries continue to evolve, the principles that underpin the success of open impeller designs will undoubtedly influence future advancements in pump and impeller technologies, paving the way for innovations that balance function, reliability, and eco-friendliness.

Authoritative case studies affirm the trustworthiness of this design in demanding applications. For example, a leading municipal wastewater treatment plant in the Midwest United States successfully transitioned to open impeller pumps, reporting a notable reduction in maintenance costs and downtime over a five-year period. These practical insights contribute to a broader understanding of how open impellers can improve reliability and performance across similar installations globally. When considering integration with existing systems, the adaptability of open impellers becomes apparent. Retrofit options are available for plants looking to upgrade from traditional impeller designs without extensive system overhauls. Industry articles emphasize the ease of installation and minimal training required for workforce adaptation, thus enhancing the appeal of open impellers to forward-thinking organizations seeking to optimize their operational framework. From a trust perspective, manufacturers and suppliers play a crucial role in endorsing the merits of open impeller designs. By providing comprehensive warranties and responsive support services, they bolster confidence in these solutions. A focus on transparent guidelines and best practices for using, maintaining, and troubleshooting open impeller systems ensures end-users benefit fully from their capabilities. Leading brands continuously invest in research and development, fostering innovation and setting benchmarks that competitors follow, thereby reinforcing the authoritative stature of open impeller technology in the market. In summary, the open impeller design remains an exemplar of engineering excellence, combining practical expertise and theoretical insights to meet the evolving demands of various industries. Its adoption reflects a strategic decision to enhance fluid dynamics efficiency, operational sustainability, and system resilience. As industries continue to evolve, the principles that underpin the success of open impeller designs will undoubtedly influence future advancements in pump and impeller technologies, paving the way for innovations that balance function, reliability, and eco-friendliness.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024