-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 10:52

Back to list

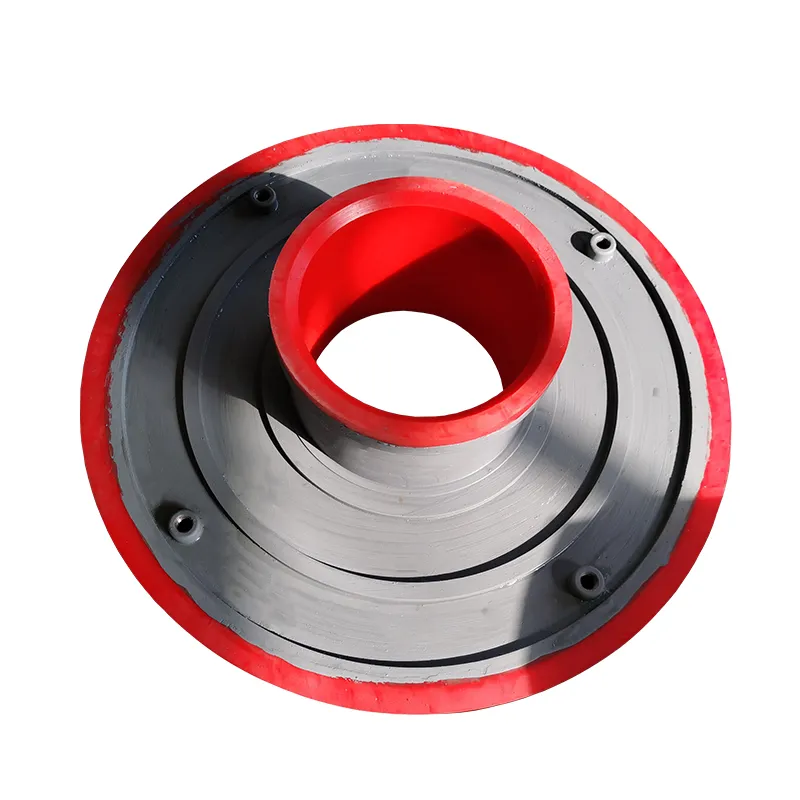

Pump Wear Parts F6147 Rubber

Positive displacement slurry pumps are pivotal in various industries where slurry processing is a critical operation. These pumps are uniquely designed to handle viscous and abrasive fluids, often laden with solid particulates that would quickly wear down traditional centrifugal pumps. Their ability to provide consistent flow rates regardless of discharge pressure makes them indispensable in mining, wastewater treatment, and construction sectors.

Trust in positive displacement slurry pumps has also been bolstered by their success in challenging environments. On construction sites, where the removal or redirection of slurry is often on an urgent timeline, their performance can be the linchpin to maintaining project deadlines. Their capacity to handle variable consistencies without a significant drop in performance ensures that operations remain on track. Furthermore, the positive displacement slurry pump industry often backs its products through rigorous testing and certifications, which adds to their trustworthiness. Compliance with industry standards like ISO and ANSI is common and provides assurance to end-users about the quality and safety of these pumps. When considering investment in a positive displacement slurry pump, experience shared by long-term users can offer invaluable insights. Many emphasize the importance of a thorough assessment of operational needs and conditions, urging potential buyers to work with manufacturers to conduct detailed demand analyses. This collaboration often includes simulation testing, which can pinpoint the most efficient configuration and materials for a given application. To maximize the potential of these pumps, regular training and updates for operational staff are recommended, ensuring they are equipped with the latest knowledge and skills to handle any issues that arise. This proactive approach not only prevents costly breakdowns but also enhances the performance and longevity of the pumping systems. In conclusion, positive displacement slurry pumps stand out for their ability to meet the demanding requirements of various industries that handle abrasive and viscous materials. Their design and efficiency promise reduced operational costs and greater reliability, while their adaptability to different operational needs underscores their importance as a key tool in industrial applications. Trust, authority, and expert advice around these pumps continue to grow, as they remain a cornerstone of successful slurry management.

Trust in positive displacement slurry pumps has also been bolstered by their success in challenging environments. On construction sites, where the removal or redirection of slurry is often on an urgent timeline, their performance can be the linchpin to maintaining project deadlines. Their capacity to handle variable consistencies without a significant drop in performance ensures that operations remain on track. Furthermore, the positive displacement slurry pump industry often backs its products through rigorous testing and certifications, which adds to their trustworthiness. Compliance with industry standards like ISO and ANSI is common and provides assurance to end-users about the quality and safety of these pumps. When considering investment in a positive displacement slurry pump, experience shared by long-term users can offer invaluable insights. Many emphasize the importance of a thorough assessment of operational needs and conditions, urging potential buyers to work with manufacturers to conduct detailed demand analyses. This collaboration often includes simulation testing, which can pinpoint the most efficient configuration and materials for a given application. To maximize the potential of these pumps, regular training and updates for operational staff are recommended, ensuring they are equipped with the latest knowledge and skills to handle any issues that arise. This proactive approach not only prevents costly breakdowns but also enhances the performance and longevity of the pumping systems. In conclusion, positive displacement slurry pumps stand out for their ability to meet the demanding requirements of various industries that handle abrasive and viscous materials. Their design and efficiency promise reduced operational costs and greater reliability, while their adaptability to different operational needs underscores their importance as a key tool in industrial applications. Trust, authority, and expert advice around these pumps continue to grow, as they remain a cornerstone of successful slurry management.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024