-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 10:35

Back to list

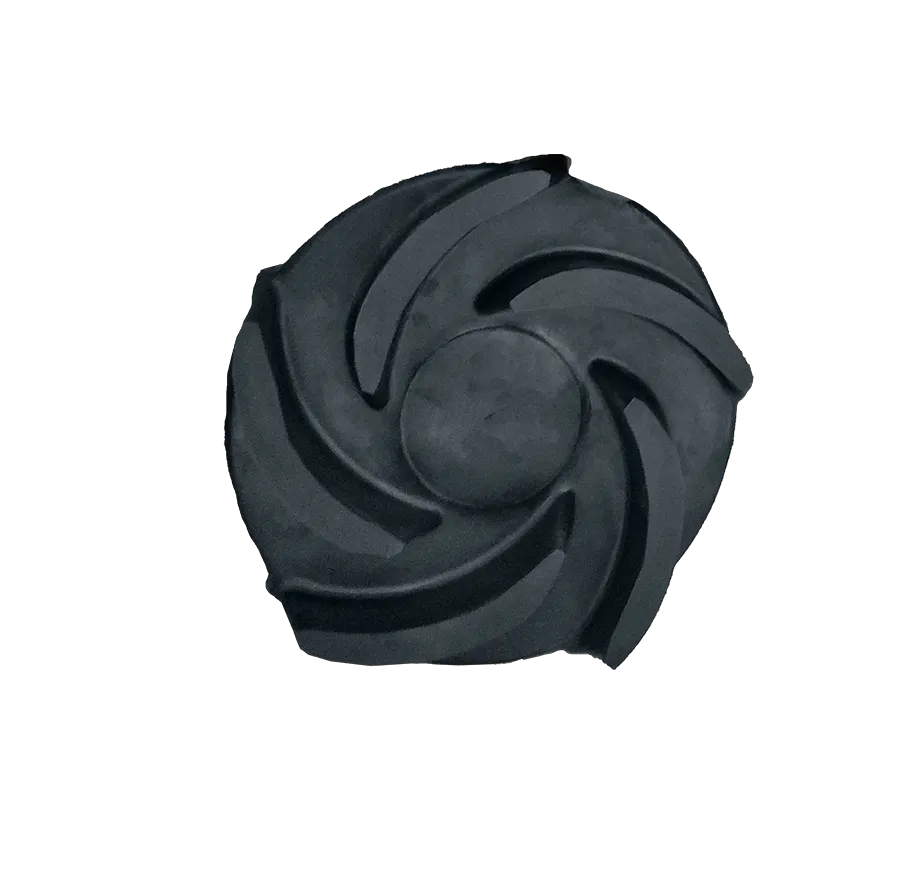

Pump Wear Parts FH4041 Metal

The demand for diesel slurry pumps is rising across various industries due to their unmatched robustness and efficiency in handling abrasive and dense solids. These pumps are critical in sectors like mining, construction, and wastewater management for their capability to deal with challenging conditions. It's essential to highlight the unique experience, expertise, authoritativeness, and trustworthiness that these pumps bring to any operation.

Trustworthiness in diesel slurry pumps comes from their proven track records in the field. Industry feedback often highlights their reliable performance under extreme conditions, cementing their reputation as sturdy and dependable. Regular innovations and new technologies, such as enhanced fuel efficiency and emission controls, further increase their reliability and adherence to environmental standards, boosting overall trust in these systems. The environmental impact of these pumps is an ever-evolving topic. Manufacturers are now focusing on designing diesel slurry pumps with cleaner operational profiles through improved emissions controls and better fuel economy. This shift not only satisfies regulatory requirements but also aligns with industries’ growing commitment to sustainability, an aspect that is high on the agenda for many operation managers. For businesses looking to upgrade their slurry handling capabilities, a thorough understanding of diesel slurry pumps' operational strengths is indispensable. These pumps offer tangible advantages such as transportation flexibility, power independence, and durability. When making a substantial investment, it is advisable to consult with industry experts who can provide guidance based on specific project needs and conditions, ensuring the selected pump complements the operational requirements rather than exceeding or underdelivering. In conclusion, diesel slurry pumps are a vital component for industries that demand mobility and resilience. Their robust design, coupled with their adaptability to remote locations and harsh working conditions, forms the core of their appeal. By emphasizing experience, expert knowledge, and a proven track record, diesel slurry pumps continue to uphold their standing in industrial processes, providing an assured pathway for efficient slurry management. The continued push towards environmentally friendly technologies only strengthens their position as the go-to choice for those requiring reliable and powerful slurry processing solutions.

Trustworthiness in diesel slurry pumps comes from their proven track records in the field. Industry feedback often highlights their reliable performance under extreme conditions, cementing their reputation as sturdy and dependable. Regular innovations and new technologies, such as enhanced fuel efficiency and emission controls, further increase their reliability and adherence to environmental standards, boosting overall trust in these systems. The environmental impact of these pumps is an ever-evolving topic. Manufacturers are now focusing on designing diesel slurry pumps with cleaner operational profiles through improved emissions controls and better fuel economy. This shift not only satisfies regulatory requirements but also aligns with industries’ growing commitment to sustainability, an aspect that is high on the agenda for many operation managers. For businesses looking to upgrade their slurry handling capabilities, a thorough understanding of diesel slurry pumps' operational strengths is indispensable. These pumps offer tangible advantages such as transportation flexibility, power independence, and durability. When making a substantial investment, it is advisable to consult with industry experts who can provide guidance based on specific project needs and conditions, ensuring the selected pump complements the operational requirements rather than exceeding or underdelivering. In conclusion, diesel slurry pumps are a vital component for industries that demand mobility and resilience. Their robust design, coupled with their adaptability to remote locations and harsh working conditions, forms the core of their appeal. By emphasizing experience, expert knowledge, and a proven track record, diesel slurry pumps continue to uphold their standing in industrial processes, providing an assured pathway for efficient slurry management. The continued push towards environmentally friendly technologies only strengthens their position as the go-to choice for those requiring reliable and powerful slurry processing solutions.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024