-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 19, 2025 23:42

Back to list

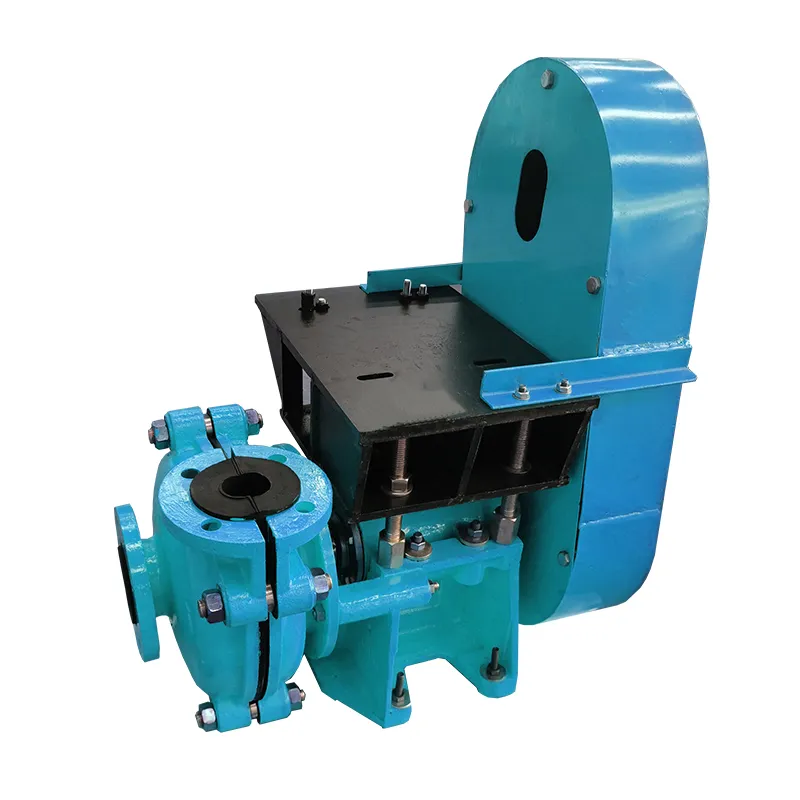

piston slurry pump

In the dynamic landscape of industrial pumping solutions, piston slurry pumps stand out as essential components with their unparalleled efficiency and versatility. These pumps are widely chosen for their robust design and the ability to handle high-viscosity slurries with ease, making them invaluable in sectors such as mining, construction, and wastewater management.

Installation and maintenance of piston slurry pumps require specialized knowledge and skills. Working alongside experienced technicians, the setup process involves calibrating the pump to match the specific needs of the application, considering factors such as slurry composition, required flow rate, and pressure. Regular maintenance, including the inspection of seals, pistons, and other wear parts, is imperative to ensure optimal performance and prevent unexpected failures. Trust in the efficiency of piston slurry pumps is further bolstered by the endorsements they receive from leading industry experts and the substantial body of positive user testimonials. These pumps have consistently demonstrated their worth in numerous case studies, showcasing their ability to reduce energy consumption and lower operational costs due to fewer breakdowns and maintenance needs compared to alternative pump types. Moreover, advancements in pump technology continue to enhance the capabilities of piston slurry pumps. Innovations such as remote monitoring and control through IoT devices are emerging, allowing operators to monitor pump performance in real-time. This technological progression not only augments the reliability of these pumps but also streamlines their operation, enabling predictive maintenance and data-driven decision-making to further improve efficiency. In conclusion, the piston slurry pump is a cornerstone of modern industrial pumping systems, providing unmatched performance and reliability. Its ability to tackle high-viscosity applications effortlessly makes it the preferred choice across various industries. Its continued evolution through technological advancements only solidifies its authority in the field. Companies seeking trustworthy and efficient pumping solutions would do well to consider piston slurry pumps as an integral part of their operational infrastructure, ensuring both cost-effectiveness and high performance in their slurry management practices.

Installation and maintenance of piston slurry pumps require specialized knowledge and skills. Working alongside experienced technicians, the setup process involves calibrating the pump to match the specific needs of the application, considering factors such as slurry composition, required flow rate, and pressure. Regular maintenance, including the inspection of seals, pistons, and other wear parts, is imperative to ensure optimal performance and prevent unexpected failures. Trust in the efficiency of piston slurry pumps is further bolstered by the endorsements they receive from leading industry experts and the substantial body of positive user testimonials. These pumps have consistently demonstrated their worth in numerous case studies, showcasing their ability to reduce energy consumption and lower operational costs due to fewer breakdowns and maintenance needs compared to alternative pump types. Moreover, advancements in pump technology continue to enhance the capabilities of piston slurry pumps. Innovations such as remote monitoring and control through IoT devices are emerging, allowing operators to monitor pump performance in real-time. This technological progression not only augments the reliability of these pumps but also streamlines their operation, enabling predictive maintenance and data-driven decision-making to further improve efficiency. In conclusion, the piston slurry pump is a cornerstone of modern industrial pumping systems, providing unmatched performance and reliability. Its ability to tackle high-viscosity applications effortlessly makes it the preferred choice across various industries. Its continued evolution through technological advancements only solidifies its authority in the field. Companies seeking trustworthy and efficient pumping solutions would do well to consider piston slurry pumps as an integral part of their operational infrastructure, ensuring both cost-effectiveness and high performance in their slurry management practices.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024