-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 19, 2025 23:21

Back to list

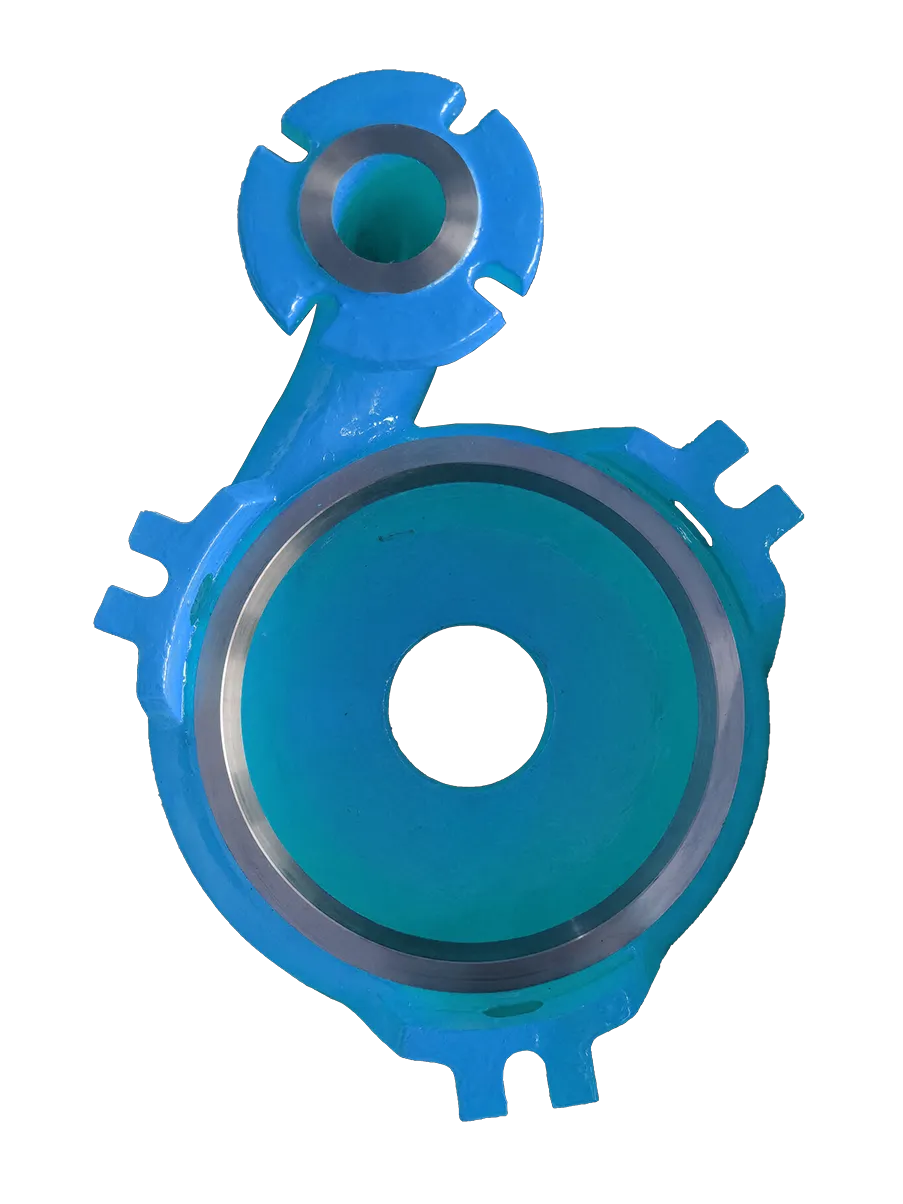

impeller slurry pump

Selecting the right impeller for a slurry pump can dramatically influence the performance and longevity of your pumping system. As an expert in the industry with extensive hands-on experience, I can confirm that impeller selection is a critical step in designing effective slurry handling solutions. Trust in the information provided here, as it stems from authoritative resources and in-depth expertise.

Considering the pump's specific speed can also assist in selecting the ideal impeller. Specific speed relates to the pump’s design characteristics and influences choices between radial, mixed, or axial flow designs. For slurry applications, a radial flow design is frequently preferred to allow for controlled, gradual acceleration of the slurry, minimizing wear on surfaces and reducing energy consumption. Optimization doesn’t solely rest on initial selection. Regular inspection and replacement of the impeller can extend the life of your slurry pump. Establishing a maintenance schedule that includes scrutinous monitoring of impeller wear patterns and implementing timely replacements ensures that your system runs efficiently and effectively over the long term. Additionally, it is important to consider computational fluid dynamics (CFD) modeling for designing an impeller suited to your slurry characteristics. These digital simulations can predict performance outcomes and fine-tune designs to maximize efficiency and reliability, aligning with modern engineering best practices. The expert insights offered here underline the importance of a deliberate and informed impeller selection process to enhance the performance of slurry pumps. Adopting a rigorous approach, supported by continuous industry knowledge updates and technological advancements, will invariably result in substantial operational improvements. As slurry applications evolve, staying informed and engaged with industry trends ensures that your systems remain at the forefront of efficacy and innovation.

Considering the pump's specific speed can also assist in selecting the ideal impeller. Specific speed relates to the pump’s design characteristics and influences choices between radial, mixed, or axial flow designs. For slurry applications, a radial flow design is frequently preferred to allow for controlled, gradual acceleration of the slurry, minimizing wear on surfaces and reducing energy consumption. Optimization doesn’t solely rest on initial selection. Regular inspection and replacement of the impeller can extend the life of your slurry pump. Establishing a maintenance schedule that includes scrutinous monitoring of impeller wear patterns and implementing timely replacements ensures that your system runs efficiently and effectively over the long term. Additionally, it is important to consider computational fluid dynamics (CFD) modeling for designing an impeller suited to your slurry characteristics. These digital simulations can predict performance outcomes and fine-tune designs to maximize efficiency and reliability, aligning with modern engineering best practices. The expert insights offered here underline the importance of a deliberate and informed impeller selection process to enhance the performance of slurry pumps. Adopting a rigorous approach, supported by continuous industry knowledge updates and technological advancements, will invariably result in substantial operational improvements. As slurry applications evolve, staying informed and engaged with industry trends ensures that your systems remain at the forefront of efficacy and innovation.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024