-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 12:10

Back to list

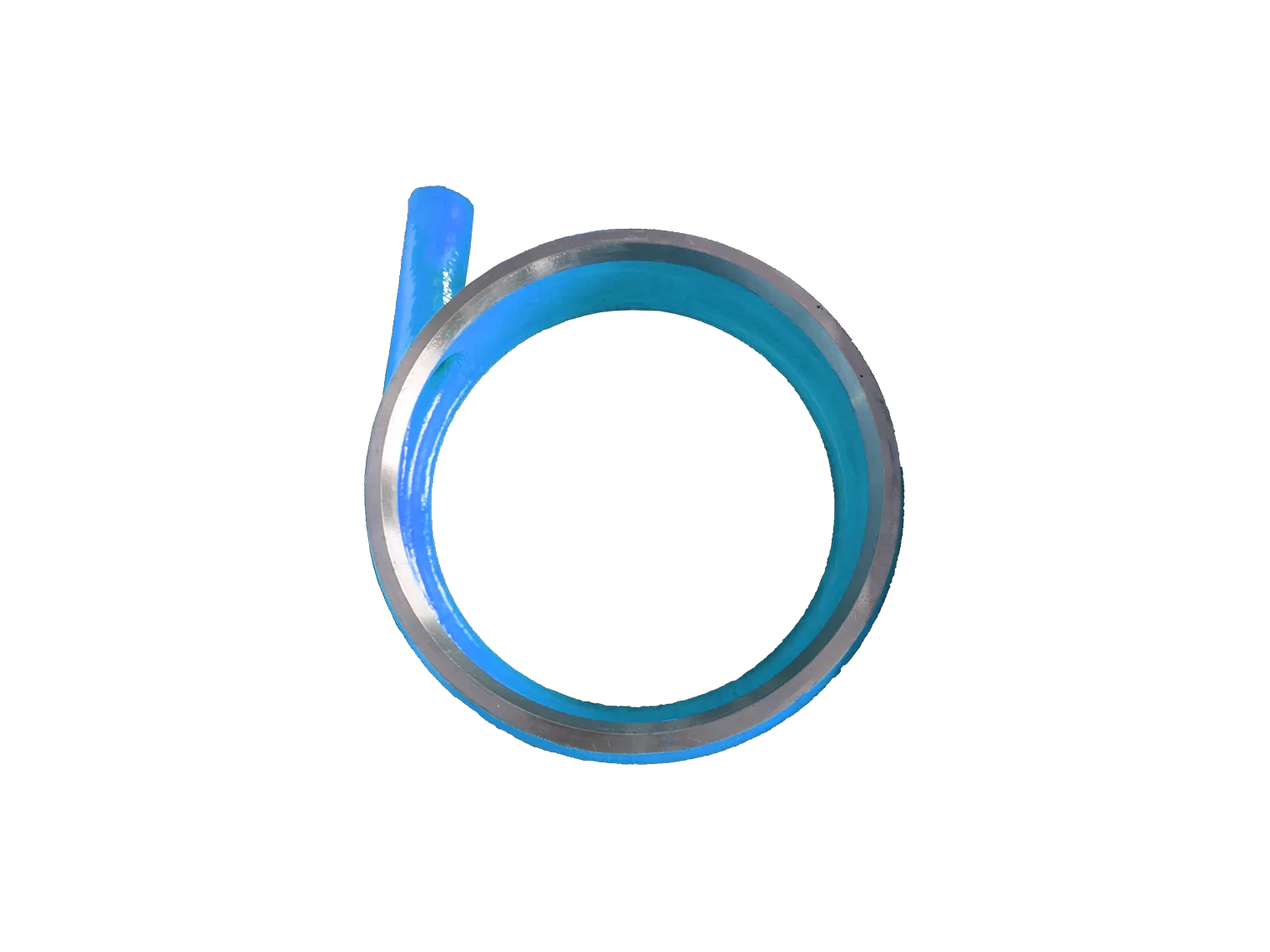

impeller casting process

The impeller casting process stands as a pivotal method in manufacturing, enhancing the efficiency and longevity of equipment across various industries. This technique, steeped in history and refined through cutting-edge innovations, has proven essential in creating robust components used in pumps, turbines, and compressors. The blend of experience, technical knowledge, authority, and trust underpin the practices that make impeller casting a cornerstone in production pipelines.

Authoritativeness in the industry also comes from a continual commitment to innovation. The integration of Industry 4.0 technologies, such as IoT sensors capturing real-time data and machine learning algorithms analyzing production metrics, drives continuous improvements. These technological advancements not only streamline the process but also provide actionable insights, enabling predictive maintenance and reducing downtime. Ultimately, the impeller casting process is more than just a manufacturing activity; it's a fusion of art and science. The journey from a raw alloy to a precision-engineered impeller embodies decades of accumulated knowledge, meticulous craftsmanship, and a commitment to excellence. Companies that master this process offer unmatched value, serving as reliable partners in industries ranging from water treatment and oil and gas to aerospace and automotive. Advancements in eco-friendly and sustainable practices further demonstrate leadership within the sector. Foundries are adopting low-energy processing methods and investing in recycling waste materials, underscoring an environmental responsibility that aligns with global sustainability goals. By reducing carbon footprints and embracing green technologies, these manufacturers bolster their reliability and align with clients' growing environmental consciousness. The impeller casting process, in essence, stands as a testament to human ingenuity and the relentless pursuit of progress. With dedicated professionals possessing profound knowledge and an unwavering commitment to quality, this process continues to innovate and adapt, responding dynamically to challenges while setting industry benchmarks. Clients seeking top-tier components need look no further than those who have perfected this process, confident in the expertise and trust that underpin every cast impeller.

Authoritativeness in the industry also comes from a continual commitment to innovation. The integration of Industry 4.0 technologies, such as IoT sensors capturing real-time data and machine learning algorithms analyzing production metrics, drives continuous improvements. These technological advancements not only streamline the process but also provide actionable insights, enabling predictive maintenance and reducing downtime. Ultimately, the impeller casting process is more than just a manufacturing activity; it's a fusion of art and science. The journey from a raw alloy to a precision-engineered impeller embodies decades of accumulated knowledge, meticulous craftsmanship, and a commitment to excellence. Companies that master this process offer unmatched value, serving as reliable partners in industries ranging from water treatment and oil and gas to aerospace and automotive. Advancements in eco-friendly and sustainable practices further demonstrate leadership within the sector. Foundries are adopting low-energy processing methods and investing in recycling waste materials, underscoring an environmental responsibility that aligns with global sustainability goals. By reducing carbon footprints and embracing green technologies, these manufacturers bolster their reliability and align with clients' growing environmental consciousness. The impeller casting process, in essence, stands as a testament to human ingenuity and the relentless pursuit of progress. With dedicated professionals possessing profound knowledge and an unwavering commitment to quality, this process continues to innovate and adapt, responding dynamically to challenges while setting industry benchmarks. Clients seeking top-tier components need look no further than those who have perfected this process, confident in the expertise and trust that underpin every cast impeller.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024