-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 11:53

Back to list

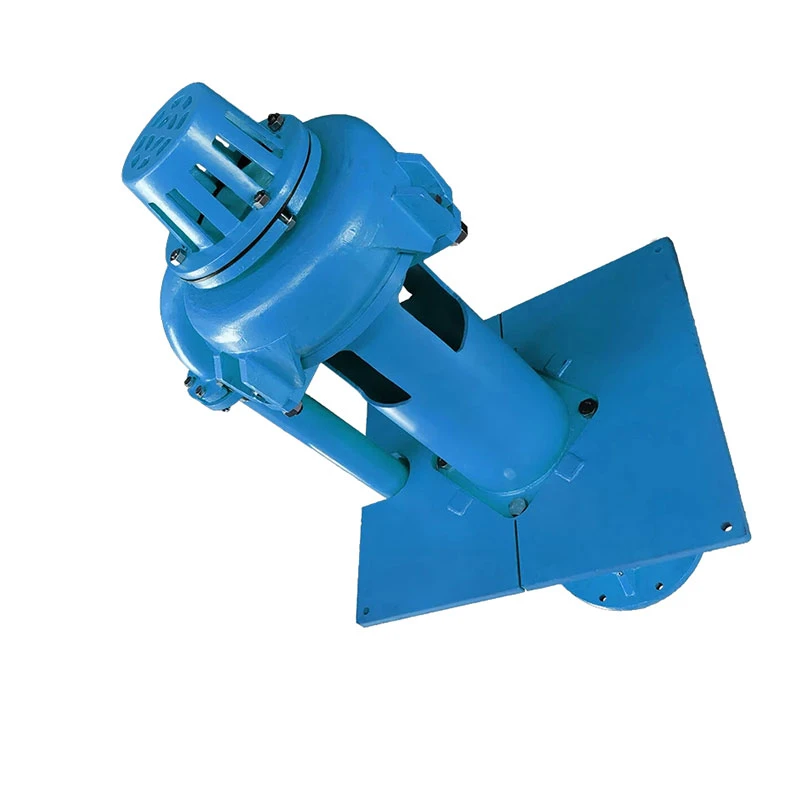

high pressure water pump impeller design

Designing a high-pressure water pump impeller is a sophisticated process that requires a deep understanding of fluid dynamics, materials science, and mechanical engineering. The impeller is the heart of a water pump, influencing its efficiency, performance, and reliability. Here’s a comprehensive guide to designing an impeller that maximizes performance while ensuring durability.

4. Real-World Testing and Validation Despite advanced simulations, real-world testing remains crucial. This involves creating prototypes and subjecting them to various performance tests under actual working conditions. It ensures the impeller can handle unexpected scenarios that simulations may not cover, such as sudden pressure spikes or temperature changes. Continuous testing helps refine the design, leading to improved reliability and lifespan of the impeller. 5. Contribution to Sustainability Sustainability is becoming increasingly important in machinery design. An efficient impeller not only saves energy but also reduces the environmental footprint of the pump. By focusing on precision engineering, modern impeller designs contribute to sustainable practices by lowering operational costs and reducing the need for frequent replacements, thus conserving resources. 6. Expert Collaboration and Knowledge Integration Finally, effective impeller design benefits from collaboration among various experts. Mechanical engineers, materials scientists, and fluid dynamics specialists each bring unique insights. Regular workshops, conferences, and industry collaborations foster innovation and knowledge exchange. By integrating diverse expertise, the development process becomes more holistic, resulting in superior impeller designs. In conclusion, designing a high-pressure water pump impeller is a multidisciplinary endeavor that demands expertise, innovation, and rigorous testing. The successful creation of a high-performance impeller hinges on selecting the appropriate type, material, and using advanced simulation tools to optimize its design. By valuing sustainability and expert collaboration, an impeller can achieve not only outstanding operational efficiency but also a longer, more reliable service life.

4. Real-World Testing and Validation Despite advanced simulations, real-world testing remains crucial. This involves creating prototypes and subjecting them to various performance tests under actual working conditions. It ensures the impeller can handle unexpected scenarios that simulations may not cover, such as sudden pressure spikes or temperature changes. Continuous testing helps refine the design, leading to improved reliability and lifespan of the impeller. 5. Contribution to Sustainability Sustainability is becoming increasingly important in machinery design. An efficient impeller not only saves energy but also reduces the environmental footprint of the pump. By focusing on precision engineering, modern impeller designs contribute to sustainable practices by lowering operational costs and reducing the need for frequent replacements, thus conserving resources. 6. Expert Collaboration and Knowledge Integration Finally, effective impeller design benefits from collaboration among various experts. Mechanical engineers, materials scientists, and fluid dynamics specialists each bring unique insights. Regular workshops, conferences, and industry collaborations foster innovation and knowledge exchange. By integrating diverse expertise, the development process becomes more holistic, resulting in superior impeller designs. In conclusion, designing a high-pressure water pump impeller is a multidisciplinary endeavor that demands expertise, innovation, and rigorous testing. The successful creation of a high-performance impeller hinges on selecting the appropriate type, material, and using advanced simulation tools to optimize its design. By valuing sustainability and expert collaboration, an impeller can achieve not only outstanding operational efficiency but also a longer, more reliable service life.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024