-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 14:36

Back to list

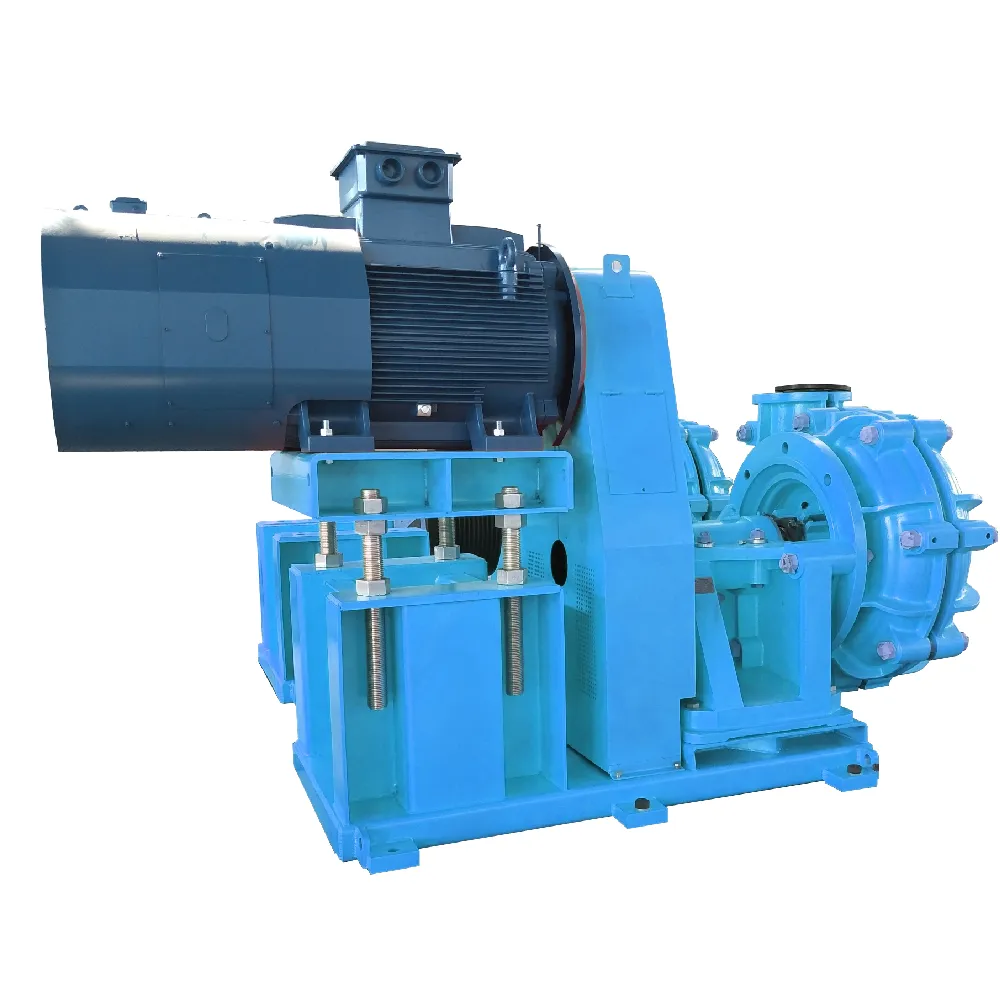

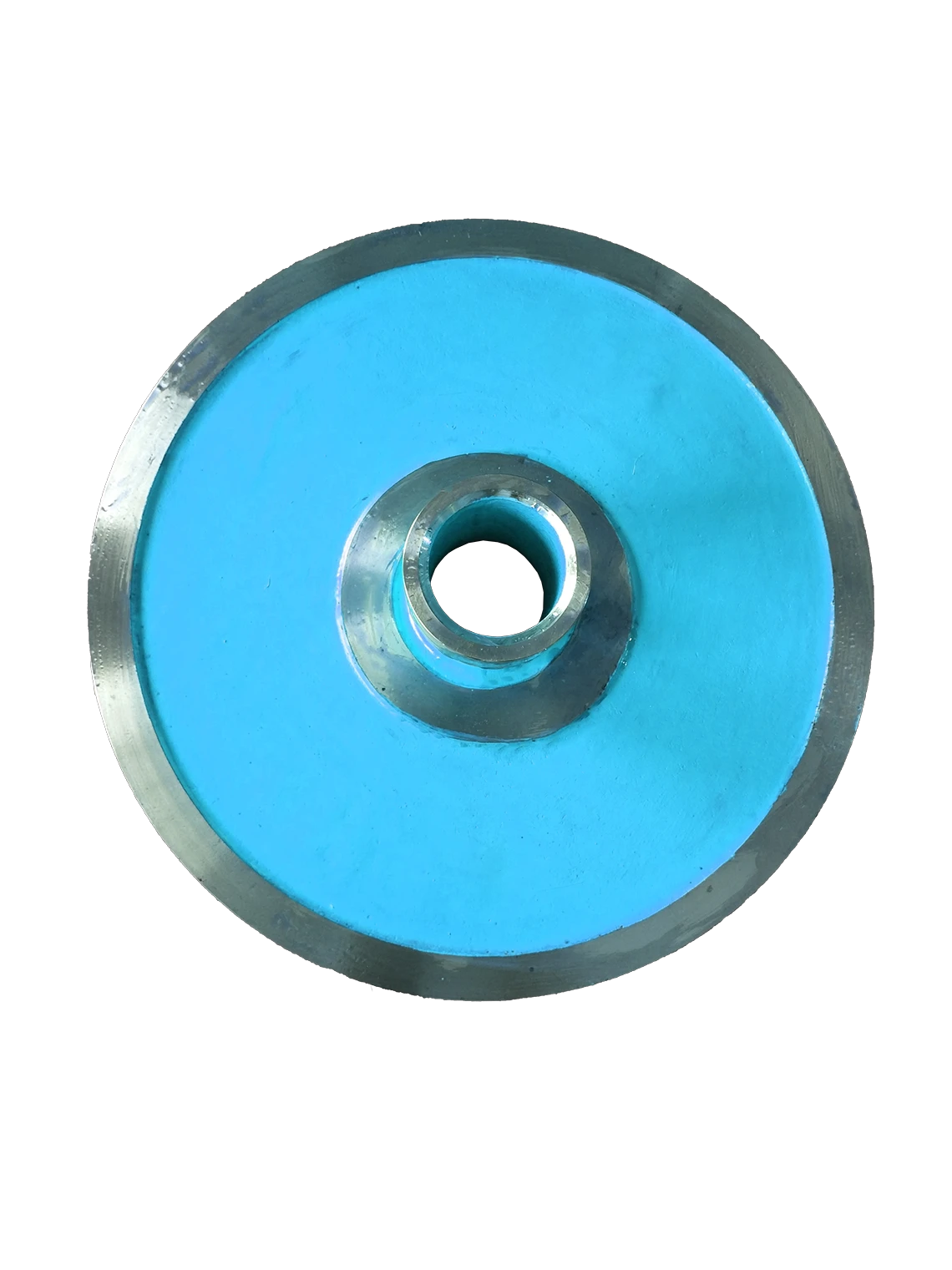

Pump Wear Parts F6147 Rubber

The function of an impeller extends beyond its traditional industrial applications; it is a critical component that has revolutionized efficiency in various sectors, including automotive, HVAC, and marine industries. This piece delves into the multifaceted roles of impellers, their intricate designs, and why choosing the right impeller is vital for optimizing machinery performance.

Trustworthiness is paramount, especially in applications involving safety-critical environments. Impellers used in areas such as aerospace or nuclear power plants undergo rigorous testing to meet industry standards and regulatory requirements. The trust users place in these components is often a reflection of their performance history, the manufacturer's reputation, and the transparency of their operation protocols. Reflecting on real-world experience, when an industrial water treatment facility faced reduced efficiency in their pumping systems, a detailed analysis revealed that the existing impellers were improperly matched to the operational requirements. Upon consulting with expert engineers, the facility opted for a series of custom-designed impellers. This change not only enhanced flow stability but also resulted in significant energy savings and reduced maintenance costs. Such case studies underscore the direct correlation between impeller selection and overall system performance. From an end-user perspective, understanding the function and importance of impellers leads to informed purchasing decisions. This involves close collaboration with suppliers, asking crucial questions about material properties, design specifications, and compatibility with existing systems. Engaging with suppliers who demonstrate expertise and authority in the field can greatly improve the likelihood of project success. In conclusion, the function of an impeller is a cornerstone in many industries, demanding a blend of real-world experience, professional expertise, authoritative innovation, and unwavering trustworthiness. By focusing on these aspects, industries not only enhance their operational efficiency but also safeguard the reliability and effectiveness of their fluid systems. As technology and design methodologies continue to evolve, the role of the impeller will undoubtedly grow, further cementing its place as a pivotal component in the machinery of the modern world.

Trustworthiness is paramount, especially in applications involving safety-critical environments. Impellers used in areas such as aerospace or nuclear power plants undergo rigorous testing to meet industry standards and regulatory requirements. The trust users place in these components is often a reflection of their performance history, the manufacturer's reputation, and the transparency of their operation protocols. Reflecting on real-world experience, when an industrial water treatment facility faced reduced efficiency in their pumping systems, a detailed analysis revealed that the existing impellers were improperly matched to the operational requirements. Upon consulting with expert engineers, the facility opted for a series of custom-designed impellers. This change not only enhanced flow stability but also resulted in significant energy savings and reduced maintenance costs. Such case studies underscore the direct correlation between impeller selection and overall system performance. From an end-user perspective, understanding the function and importance of impellers leads to informed purchasing decisions. This involves close collaboration with suppliers, asking crucial questions about material properties, design specifications, and compatibility with existing systems. Engaging with suppliers who demonstrate expertise and authority in the field can greatly improve the likelihood of project success. In conclusion, the function of an impeller is a cornerstone in many industries, demanding a blend of real-world experience, professional expertise, authoritative innovation, and unwavering trustworthiness. By focusing on these aspects, industries not only enhance their operational efficiency but also safeguard the reliability and effectiveness of their fluid systems. As technology and design methodologies continue to evolve, the role of the impeller will undoubtedly grow, further cementing its place as a pivotal component in the machinery of the modern world.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024