-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 11:00

Back to list

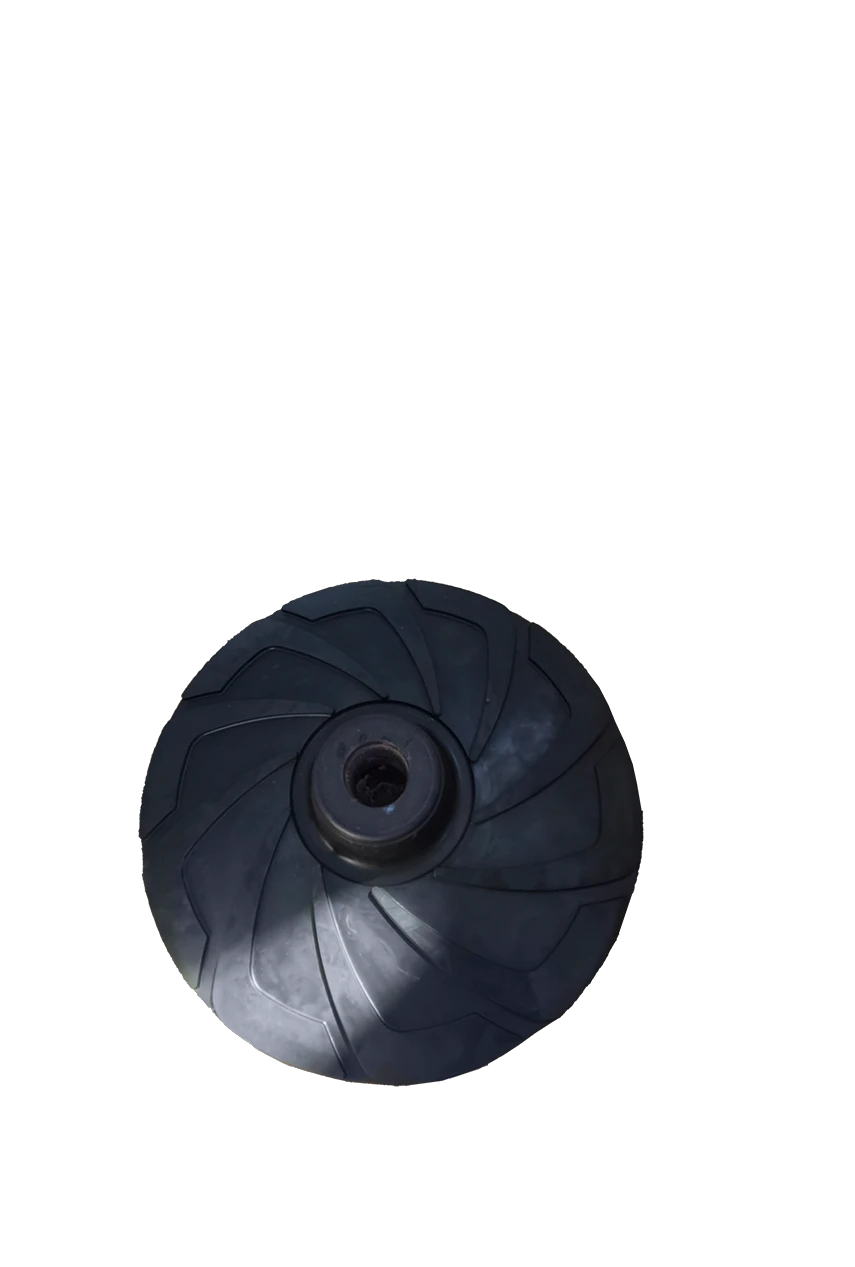

design of impeller

Designing an impeller is a task that demands a profound amalgamation of engineering precision and creative insight. An impeller, a critical component in pumps and turbines, is essential for fluid movement across various industries such as aeronautics, petrochemical, and water treatment. This article delves into the advanced nuances of impeller design by harnessing years of experience and technical expertise.

Impeller design demands an authoritative approach to vibration analysis. Precision in balancing the impeller is crucial to avert premature wear and mechanical failures. This is often achieved by leveraging both experimental techniques and finite element analysis (FEA) simulations. The latter offers a digital approximation of stress distribution, helping designers preemptively address potential structural vulnerabilities. Trustworthiness in impeller engineering is frequently established by rigorous field testing and adherence to international standards, ensuring that units comply with industry benchmarks such as ISO 9906 for hydraulic performance. Real-world validation through endurance testing helps ascertain long-term resilience, essentially aligning with authentic performance claims. In product-oriented environments, the customization of impeller designs to client-specific needs highlights trustworthiness and expertise. Tailoring the dimensions, material, and blade arrangement of an impeller based on individual application scenarios provides bespoke solutions that cater to unique operational challenges. Moreover, ongoing collaboration with domain experts ensures updates and refinements align with technological advancements and client feedback. In conclusion, the design of an impeller is a sophisticated process that integrates experience, cutting-edge technology, and credible, authoritative practices. Each design decision must reflect a deep understanding of mechanical physics, meticulous attention to detail, and a commitment to quality, ensuring that the final product not only meets but exceeds industry expectations. Such dedication to innovation and excellence craft an impeller that stands as a testament to engineering prowess and reliability.

Impeller design demands an authoritative approach to vibration analysis. Precision in balancing the impeller is crucial to avert premature wear and mechanical failures. This is often achieved by leveraging both experimental techniques and finite element analysis (FEA) simulations. The latter offers a digital approximation of stress distribution, helping designers preemptively address potential structural vulnerabilities. Trustworthiness in impeller engineering is frequently established by rigorous field testing and adherence to international standards, ensuring that units comply with industry benchmarks such as ISO 9906 for hydraulic performance. Real-world validation through endurance testing helps ascertain long-term resilience, essentially aligning with authentic performance claims. In product-oriented environments, the customization of impeller designs to client-specific needs highlights trustworthiness and expertise. Tailoring the dimensions, material, and blade arrangement of an impeller based on individual application scenarios provides bespoke solutions that cater to unique operational challenges. Moreover, ongoing collaboration with domain experts ensures updates and refinements align with technological advancements and client feedback. In conclusion, the design of an impeller is a sophisticated process that integrates experience, cutting-edge technology, and credible, authoritative practices. Each design decision must reflect a deep understanding of mechanical physics, meticulous attention to detail, and a commitment to quality, ensuring that the final product not only meets but exceeds industry expectations. Such dedication to innovation and excellence craft an impeller that stands as a testament to engineering prowess and reliability.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024