-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 10:38

Back to list

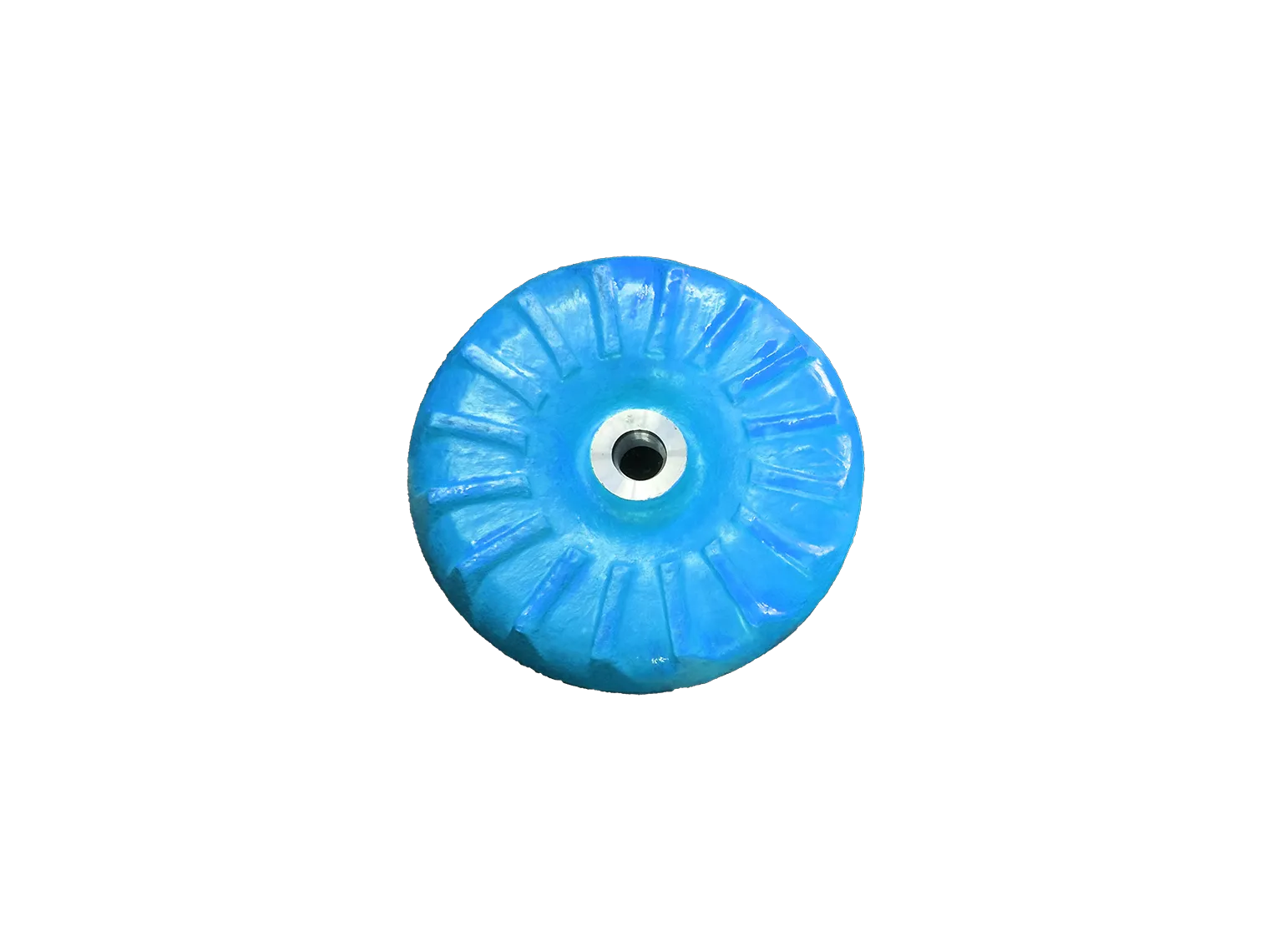

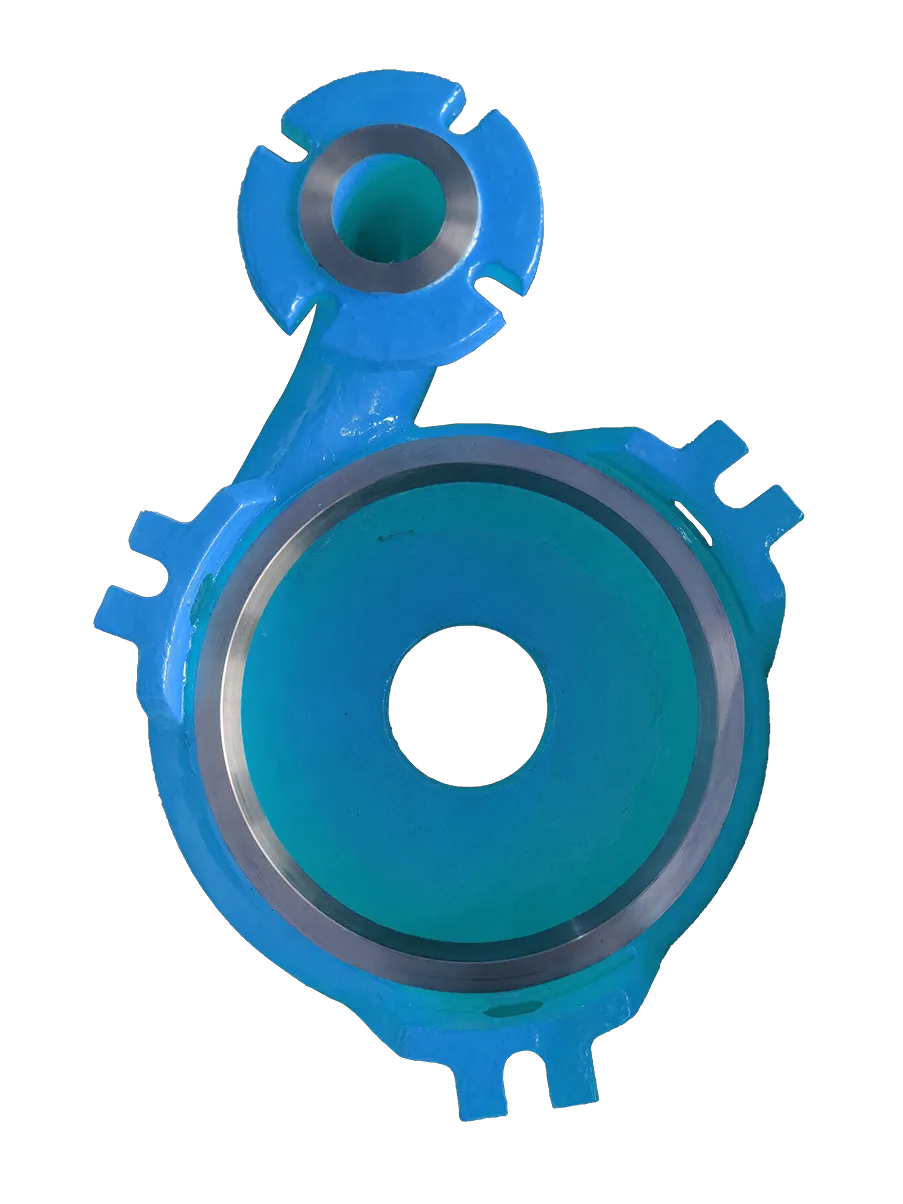

design of centrifugal pump impeller

The design of a centrifugal pump impeller is a critical aspect that influences the performance, efficiency, and longevity of pumps widely used across various industries, including water treatment, oil and gas, and chemical processing. To create an impeller design that not only optimizes performance but also ensures cost-effectiveness and durability, engineers must consider a multitude of factors and employ cutting-edge techniques both in design and testing phases.

Material selection is another critical aspect where experience and expertise play a vital role. Traditional materials like cast iron have been largely eclipsed by advanced composites and alloys, such as stainless steel, or even titanium for corrosive environments. Choosing the right material balances between cost, weight, durability, and resistance to chemical and physical wear. The life span of the impeller—and indeed the entire pump apparatus—is greatly enhanced through judicious selection of materials, informed by extensive empirical research and field data. Trustworthiness in impeller design is further solidified through stringent testing cycles. After initial digital validation via CFD, prototypes undergo rigorous physical testing to simulate real-world conditions. Vibration analysis, fatigue testing, and an array of operational assessments ensure every impeller meets operational reliability demands. Only through such exhaustive testing does a design gain the authority needed to assure clients of safety, efficiency, and performance. Beyond the technical, manufacturing processes have evolved to support sophisticated impeller designs. Techniques such as 3D printing and precision casting have enabled complex geometries to be realized that were previously impractical. These processes offer significant reductions in manufacturing time and offer precision that enhances both the performance and aesthetics of the impeller. In conclusion, the design of a centrifugal pump impeller demands a holistic approach that integrates engineering principles, cutting-edge technology, and a thorough understanding of material science. Strong attention to detail across design, simulation, and testing pipelines not only encourages innovations in fluid dynamics but also substantiates claims of expertise and authority in the field. As global industries continue to rely on efficient fluid movement, the role of the expertly designed impeller remains pivotal, driving both scientific and economic efficiencies. Through leveraging both technological advancements and empirical wisdom, engineers can craft impellers that stand as testaments to reliability and advanced engineering.

Material selection is another critical aspect where experience and expertise play a vital role. Traditional materials like cast iron have been largely eclipsed by advanced composites and alloys, such as stainless steel, or even titanium for corrosive environments. Choosing the right material balances between cost, weight, durability, and resistance to chemical and physical wear. The life span of the impeller—and indeed the entire pump apparatus—is greatly enhanced through judicious selection of materials, informed by extensive empirical research and field data. Trustworthiness in impeller design is further solidified through stringent testing cycles. After initial digital validation via CFD, prototypes undergo rigorous physical testing to simulate real-world conditions. Vibration analysis, fatigue testing, and an array of operational assessments ensure every impeller meets operational reliability demands. Only through such exhaustive testing does a design gain the authority needed to assure clients of safety, efficiency, and performance. Beyond the technical, manufacturing processes have evolved to support sophisticated impeller designs. Techniques such as 3D printing and precision casting have enabled complex geometries to be realized that were previously impractical. These processes offer significant reductions in manufacturing time and offer precision that enhances both the performance and aesthetics of the impeller. In conclusion, the design of a centrifugal pump impeller demands a holistic approach that integrates engineering principles, cutting-edge technology, and a thorough understanding of material science. Strong attention to detail across design, simulation, and testing pipelines not only encourages innovations in fluid dynamics but also substantiates claims of expertise and authority in the field. As global industries continue to rely on efficient fluid movement, the role of the expertly designed impeller remains pivotal, driving both scientific and economic efficiencies. Through leveraging both technological advancements and empirical wisdom, engineers can craft impellers that stand as testaments to reliability and advanced engineering.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024