-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

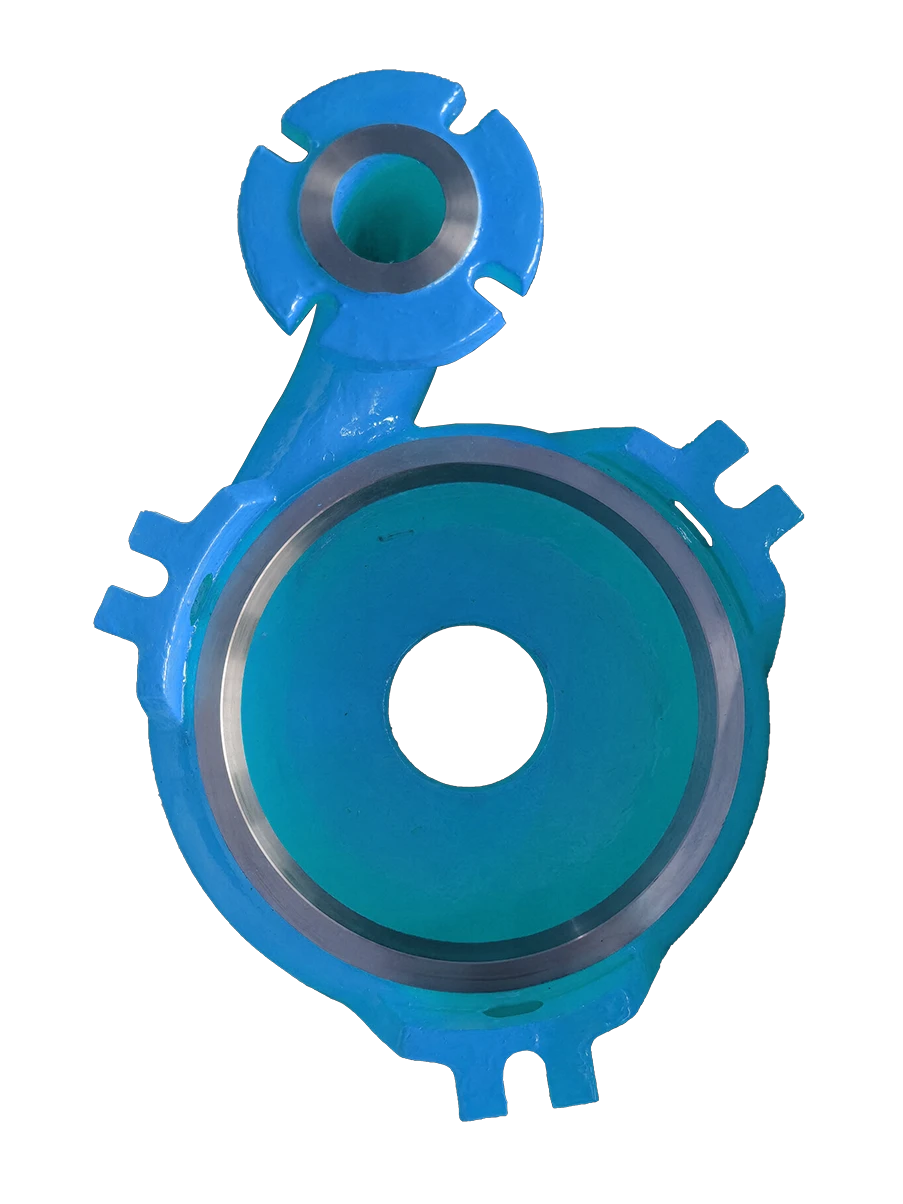

3 types of impeller

Understanding the Three Types of Impellers A Comprehensive Overview

Impellers play a crucial role in various engineering applications, particularly in pumps, compressors, and turbines. Their primary function is to convert rotational energy, usually from an electric motor or engine, into kinetic energy in a fluid. This transformation is essential in enabling fluid movement, making impellers critical components in many industrial processes. Impellers come in various shapes and designs, each tailored to serve specific purposes. In this article, we will explore three major types of impellers the radial impeller, the axial impeller, and the mixed flow impeller.

Radial impellers, also known as centrifugal impellers, are primarily designed to move fluid outward from the center of the impeller. They achieve this by utilizing a rotational motion that throws the fluid away from the shaft axis. The design typically features blades that are curved or straight, arranged radially around the central axis.

Applications Radial impellers are commonly used in centrifugal pumps, industrial fans, and blowers. These impellers excel in applications where high flow rates and moderate pressure increases are required. They are particularly effective in handling fluids with low viscosity and minimizing the risk of cavitation, a phenomenon that can lead to damage and decreased efficiency.

Advantages One of the key advantages of radial impellers is their ability to deliver high efficiencies at various flow rates. They tend to offer robust performance and reliable operation in a variety of conditions. Moreover, radial designs can handle larger volumes of liquid due to their construction, making them suitable for large-scale industrial applications.

2. Axial Impellers

In contrast to radial impellers, axial impellers move fluid along the same axis as the rotation. The design typically consists of blades that are angled or pitched, allowing the fluid to be drawn into the impeller and pushed out in a linear direction. This straight-flow design creates a high flow rate with relatively low pressure increases.

3 types of impeller

Applications Axial impellers are widely used in applications such as propellers, axial fans, and water turbines. They are particularly valuable in scenarios where large volumes of fluid need to be moved at lower pressure differentials. This makes them ideal for cooling systems, ventilation, and water pumping.

Advantages The principal advantage of axial impellers lies in their ability to handle substantial flow rates efficiently. They operate effectively in low-pressure applications, making them preferable in environments where minimal energy consumption is crucial. Additionally, axial impellers typically have fewer moving parts, which can lead to lower maintenance requirements over time.

3. Mixed Flow Impellers

Mixed flow impellers combine characteristics of both radial and axial impellers. They are designed to move fluid both radially and axially, creating a unique flow pattern that allows for higher pressure increases than an axial impeller while maintaining relatively high flow rates. The blades of a mixed flow impeller are angled in such a way that fluid enters at an angle and moves out both radially and axially.

Applications Mixed flow impellers find their utility in applications where versatility is required. They are often employed in vertical pumps, certain types of hydraulic turbines, and in various water treatment facilities. Their ability to adapt to different flow conditions makes them suitable for a broad range of industrial uses.

Advantages The mixed flow design offers a balance between high flow capacity and significant pressure increase. This makes mixed flow impellers an attractive option for many engineering scenarios requiring both speed and pressure. They are especially effective in applications facing variable fluid characteristics or changing operational conditions.

Conclusion

Understanding the different types of impellers—radial, axial, and mixed flow—is essential for engineers and professionals involved in fluid dynamics and mechanical design. Each type comes with its unique set of applications, benefits, and operational characteristics. By selecting the appropriate impeller type for a specific application, one can enhance efficiency, ensure durability, and optimize performance. As technology continues to evolve, further innovations in impeller design will likely lead to even greater efficiencies and capabilities in fluid handling processes across various industries.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024