-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 05, 2025 00:33

Back to list

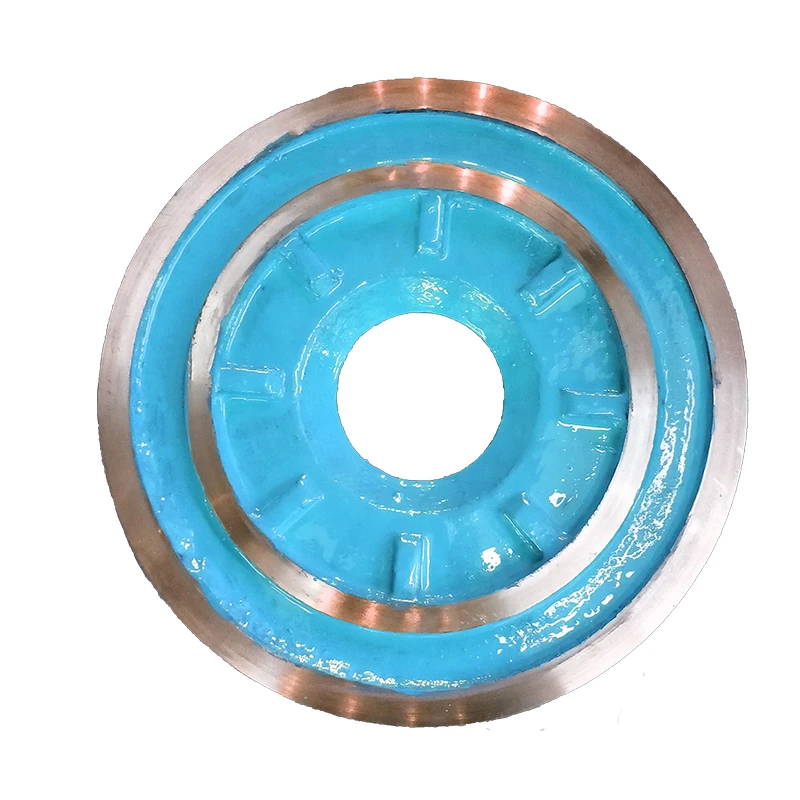

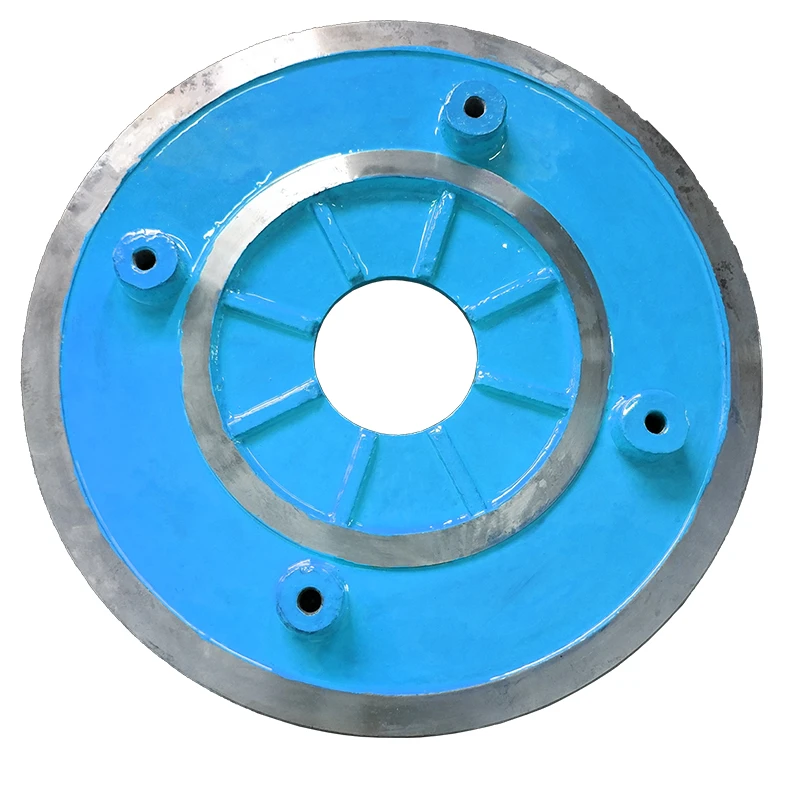

wholesale slurry pump parts

In the world of industrial applications, the necessity for robust and efficient component systems cannot be overstated, especially when dealing with slurry in various industries such as mining, power generation, and wastewater treatment. Slurry pump parts are integral components in these sectors, designed to efficiently move a mixture of liquid and solid particles via a hydraulic mechanism. Understanding the intricacies of wholesale slurry pump parts is crucial for businesses seeking not only to enhance their operational capacities but also to ensure sustainability and cost-effectiveness over time.

One authoritative voice in the industry emphasizes the significance of leveraging advanced technology in the design and production of slurry pump parts. Innovations in computational fluid dynamics (CFD) and materials science have led to improvements in the efficiency and lifespan of these components, offering businesses a competitive edge. Companies that tap into suppliers who integrate these technological advancements into their manufacturing processes often witness superior pump performance and an enhanced capability to handle more abrasive slurry materials with ease. Furthermore, establishing trust with a wholesale supplier is of paramount importance. A reliable distributor not only supplies high-quality parts but also offers expert consultation services to align their product offerings with the operational goals of each client. An authoritative supplier will typically provide extensive documentation and support, from installation guides to maintenance schedules, ensuring customers are well-equipped to maximize the utility of their investment. Increased attention to sustainable practices is also becoming a vital consideration within the industry. Many suppliers now focus on environmentally friendly manufacturing processes and the creation of parts that can be recycled or remanufactured. This not only impacts the purchasing decision positively by aligning with corporate sustainability goals but also potentially lowers the total cost of ownership by extending the lifecycle of the pump systems. In conclusion, navigating the market for wholesale slurry pump parts requires a judicious mix of technical knowledge, strategic purchasing, and a keen understanding of industrial requirements. By prioritizing performance, durability, and environmental sustainability in their choice of pump parts, businesses can achieve operational excellence while maximizing their return on investment.

One authoritative voice in the industry emphasizes the significance of leveraging advanced technology in the design and production of slurry pump parts. Innovations in computational fluid dynamics (CFD) and materials science have led to improvements in the efficiency and lifespan of these components, offering businesses a competitive edge. Companies that tap into suppliers who integrate these technological advancements into their manufacturing processes often witness superior pump performance and an enhanced capability to handle more abrasive slurry materials with ease. Furthermore, establishing trust with a wholesale supplier is of paramount importance. A reliable distributor not only supplies high-quality parts but also offers expert consultation services to align their product offerings with the operational goals of each client. An authoritative supplier will typically provide extensive documentation and support, from installation guides to maintenance schedules, ensuring customers are well-equipped to maximize the utility of their investment. Increased attention to sustainable practices is also becoming a vital consideration within the industry. Many suppliers now focus on environmentally friendly manufacturing processes and the creation of parts that can be recycled or remanufactured. This not only impacts the purchasing decision positively by aligning with corporate sustainability goals but also potentially lowers the total cost of ownership by extending the lifecycle of the pump systems. In conclusion, navigating the market for wholesale slurry pump parts requires a judicious mix of technical knowledge, strategic purchasing, and a keen understanding of industrial requirements. By prioritizing performance, durability, and environmental sustainability in their choice of pump parts, businesses can achieve operational excellence while maximizing their return on investment.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024