-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 08, 2025 03:49

Back to list

what is wear ring in centrifugal pump

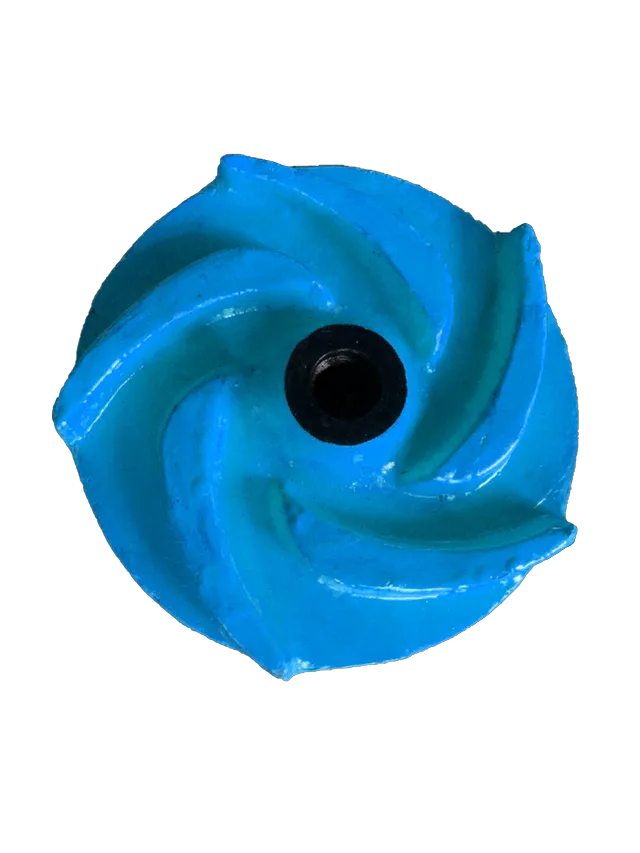

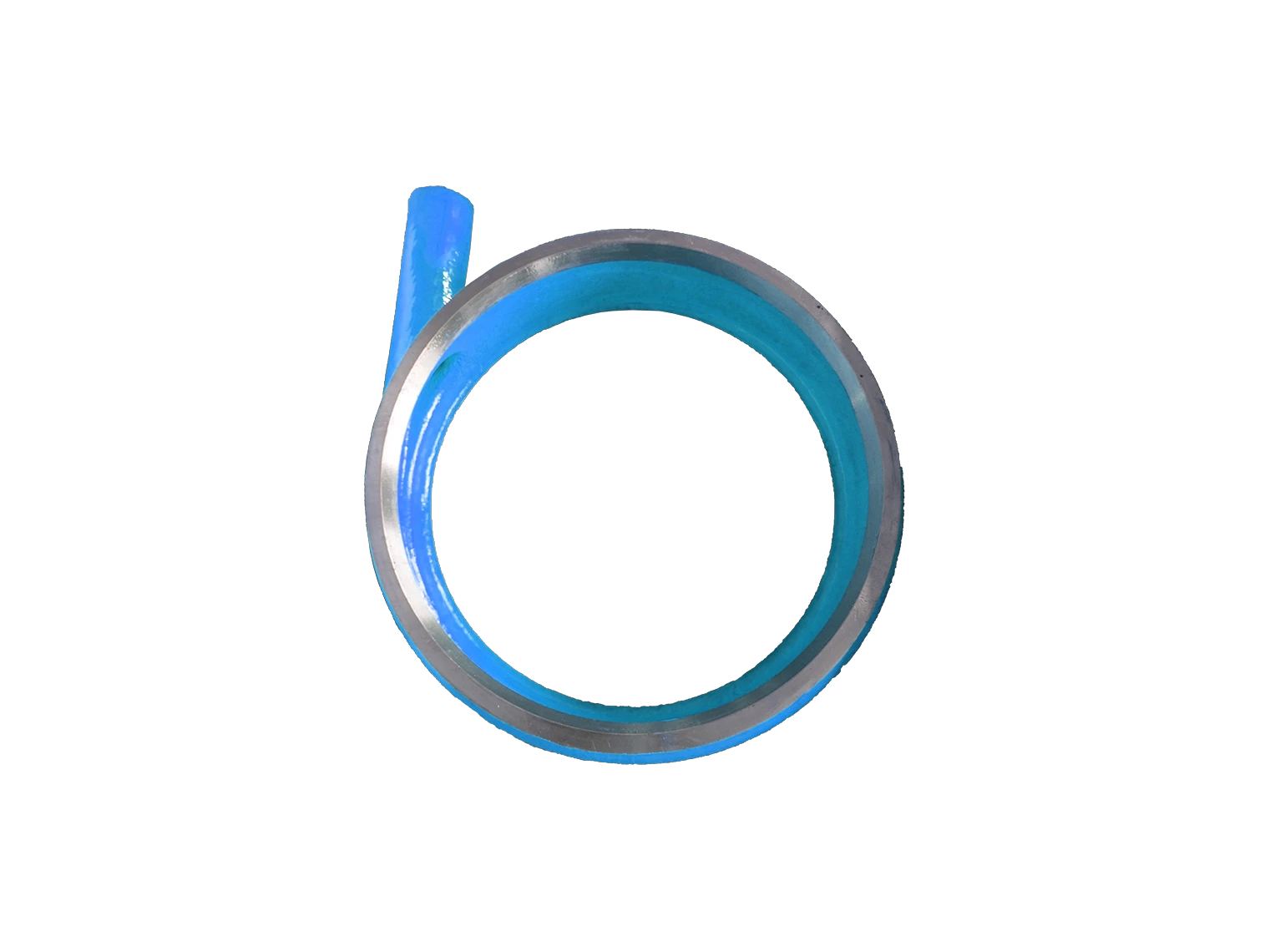

Wear rings in centrifugal pumps are an essential component that significantly enhances the pump's efficiency and lifespan. By reducing the gap between the impeller and the pump casing, wear rings minimize leakage and maintain the desired pressure within the system, thus optimizing performance. This vital functionality extends beyond mere operations, embedding itself into the essence of what makes centrifugal pumps so reliable and cost-effective in diverse industrial applications.

From an authoritative standpoint, it is beneficial to leverage insights and research from industrial leaders and publications. Industry leaders like the Hydraulic Institute and other reputable bodies offer extensive guidelines and standards regarding the implementation and maintenance of wear rings. By following these established standards, companies can bolster their maintenance strategies and align their operations with internationally recognized practices, thereby enhancing their trustworthiness and reputation in the marketplace. Real-world experience and case studies reinforce the significant impact of wear rings in centrifugal pumps. For example, a manufacturing plant that dealt with highly viscous and abrasive fluids witnessed a remarkable improvement in pump life by upgrading to a custom-tailored wear ring design. This real-life scenario underscores the importance of aligning wear ring features with specific operational environments, thereby eliminating inefficiencies and reducing environmental footprint. Trustworthiness further extends into sustainability considerations. Many modern industries are opting for wear rings that are not just durable but also recyclable. By investing in wear rings that align with environmental sustainability goals, organizations demonstrate their commitment to responsible resource management. Consequently, this commitment enhances their credibility and appeal, especially among environmentally-conscious stakeholders and customers. To sum up, wear rings in centrifugal pumps embody a pivotal element that bridges operational efficacy with sustainable practices. By strategically employing wear rings crafted from the right materials and adhering to expert recommendations, businesses can expect to not only achieve peak pump performance but also significantly extend the operational life of their equipment. This comprehensive understanding of wear rings integrates expertise, authority, and trust, thereby crafting a roadmap where technological excellence converges with sustainable industrial practices.

From an authoritative standpoint, it is beneficial to leverage insights and research from industrial leaders and publications. Industry leaders like the Hydraulic Institute and other reputable bodies offer extensive guidelines and standards regarding the implementation and maintenance of wear rings. By following these established standards, companies can bolster their maintenance strategies and align their operations with internationally recognized practices, thereby enhancing their trustworthiness and reputation in the marketplace. Real-world experience and case studies reinforce the significant impact of wear rings in centrifugal pumps. For example, a manufacturing plant that dealt with highly viscous and abrasive fluids witnessed a remarkable improvement in pump life by upgrading to a custom-tailored wear ring design. This real-life scenario underscores the importance of aligning wear ring features with specific operational environments, thereby eliminating inefficiencies and reducing environmental footprint. Trustworthiness further extends into sustainability considerations. Many modern industries are opting for wear rings that are not just durable but also recyclable. By investing in wear rings that align with environmental sustainability goals, organizations demonstrate their commitment to responsible resource management. Consequently, this commitment enhances their credibility and appeal, especially among environmentally-conscious stakeholders and customers. To sum up, wear rings in centrifugal pumps embody a pivotal element that bridges operational efficacy with sustainable practices. By strategically employing wear rings crafted from the right materials and adhering to expert recommendations, businesses can expect to not only achieve peak pump performance but also significantly extend the operational life of their equipment. This comprehensive understanding of wear rings integrates expertise, authority, and trust, thereby crafting a roadmap where technological excellence converges with sustainable industrial practices.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024