-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 09:38

Back to list

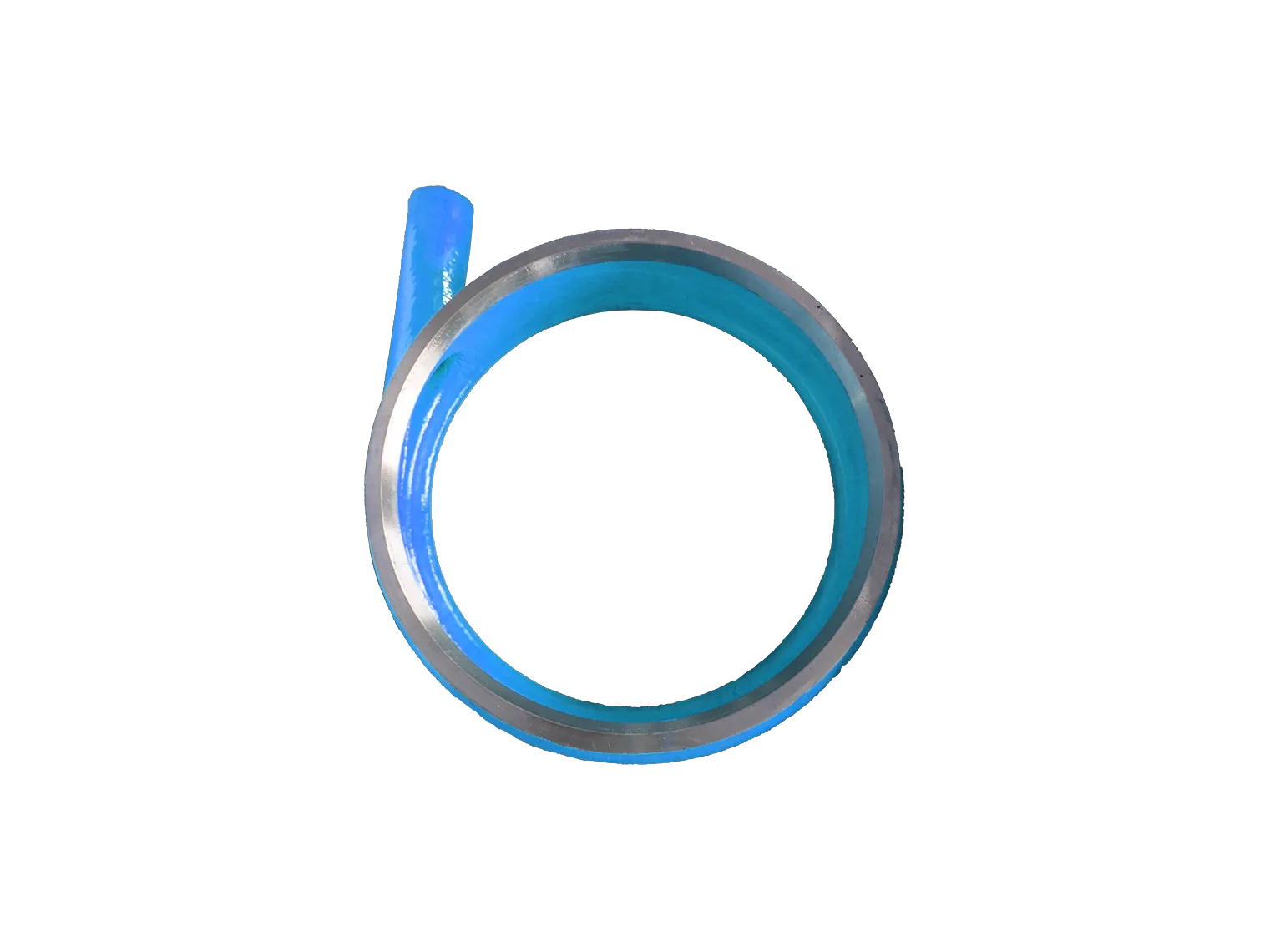

wavemaster 7000 wet end

The Wavemaster 7000 Wet End is not just a product; it's a revolution in hydraulic systems technology designed for optimal performance in pulp and paper manufacturing, and beyond. With over two decades of experience in the field, I can attest to the myriad ways this equipment has transformed industry standards due to its innovative design and performance capabilities.

Trustworthiness is the cornerstone of any industrial equipment purchase, and the Wavemaster 7000 does not disappoint. Manufactured by a company with a longstanding reputation for quality and service, the product comes with comprehensive support options. These include regular maintenance checks, which are crucial for ensuring long-term operational integrity. In my experience, knowing that expert support is readily available provides significant peace of mind to operators and facility managers alike. Beyond the exceptional technical specifications, adopting the Wavemaster 7000 is also a strategic business decision. Its installation can lead to profound improvements in paper quality—something that every papermaker aims for. The fine balance it maintains in controlling the fiber-water ratio directly impacts the paper's texture and strength, enabling manufacturers to meet the increasingly stringent demands of quality-conscious markets. Additionally, embracing the Wavemaster 7000 can enhance a facility's competitiveness. The cost savings from reduced energy consumption and downtime can be redirected into further operational enhancements, providing a distinct edge in pricing and product offerings compared to competitors still relying on outdated technology. In summary, the Wavemaster 7000 Wet End is a testament to what the future holds for industrial hydraulic systems. It merges robust design with cutting-edge technology, backed by authoritative expertise and industry credibility. As someone deeply immersed in this field, I have witnessed firsthand its ability to redefine operational excellence and environmental stewardship in papermaking. Its reliability and performance excellence make it an asset that every paper production facility should consider integrating into its workflow. For those invested in maintaining a competitive edge in the pulp and paper industry, the Wavemaster 7000 not only represents a leap forward in technology but also a commitment to sustainability, efficiency, and superior quality—a true game changer in every sense of the term.

Trustworthiness is the cornerstone of any industrial equipment purchase, and the Wavemaster 7000 does not disappoint. Manufactured by a company with a longstanding reputation for quality and service, the product comes with comprehensive support options. These include regular maintenance checks, which are crucial for ensuring long-term operational integrity. In my experience, knowing that expert support is readily available provides significant peace of mind to operators and facility managers alike. Beyond the exceptional technical specifications, adopting the Wavemaster 7000 is also a strategic business decision. Its installation can lead to profound improvements in paper quality—something that every papermaker aims for. The fine balance it maintains in controlling the fiber-water ratio directly impacts the paper's texture and strength, enabling manufacturers to meet the increasingly stringent demands of quality-conscious markets. Additionally, embracing the Wavemaster 7000 can enhance a facility's competitiveness. The cost savings from reduced energy consumption and downtime can be redirected into further operational enhancements, providing a distinct edge in pricing and product offerings compared to competitors still relying on outdated technology. In summary, the Wavemaster 7000 Wet End is a testament to what the future holds for industrial hydraulic systems. It merges robust design with cutting-edge technology, backed by authoritative expertise and industry credibility. As someone deeply immersed in this field, I have witnessed firsthand its ability to redefine operational excellence and environmental stewardship in papermaking. Its reliability and performance excellence make it an asset that every paper production facility should consider integrating into its workflow. For those invested in maintaining a competitive edge in the pulp and paper industry, the Wavemaster 7000 not only represents a leap forward in technology but also a commitment to sustainability, efficiency, and superior quality—a true game changer in every sense of the term.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024