-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 15:50

Back to list

Vertical Slurry Pumps MM40PV-SP

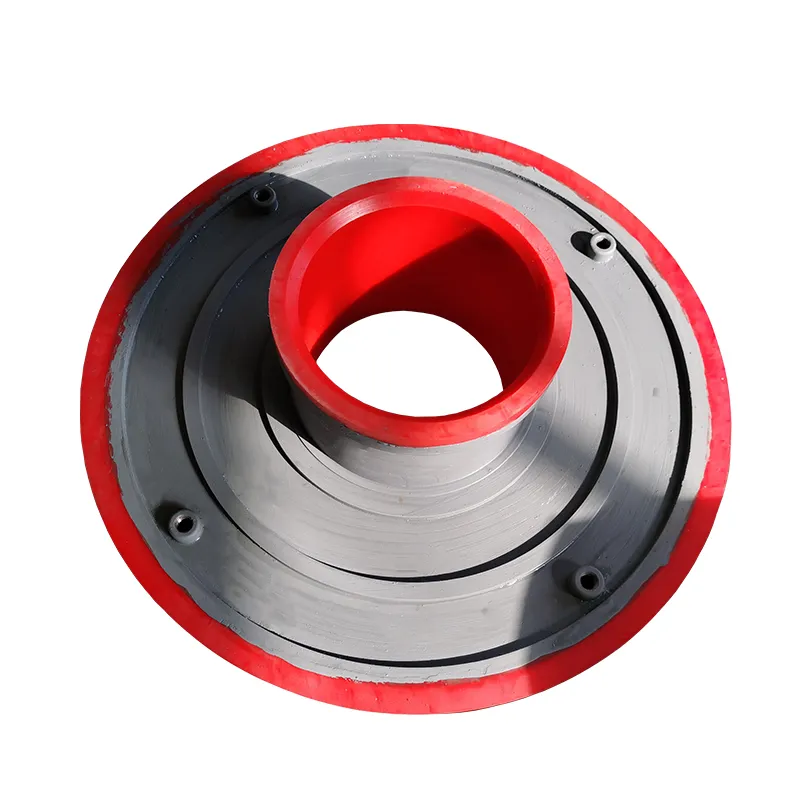

The volute of a pump is a critical component, intricately designed to improve the efficiency and performance of centrifugal pumps. In stark contrast to merely being a static cast element, the volute serves the vital purpose of gradually decreasing the velocity of a fluid, thereby converting kinetic energy into pressure. This crucial function not only enhances the pump's effectiveness but also boosts its operational stability, ensuring a prolonged lifespan and reduced maintenance needs.

Authoritativeness is underlined by the fact that volute design is guided by internationally recognized standards and certifications. Regulatory bodies and associations such as the Hydraulic Institute set rigorous benchmarks for pump components, including the volute. Professionals certified by these bodies bring a level of authority and trust to their work that reassures end-users about the reliability and efficiency of the pumps they install. Trustworthiness in pump systems hinges on the durability and consistency of the volute's performance over time. The choice of materials for the volute is as critical as its design. Materials such as stainless steel, cast iron, and high-duty alloys are widely trusted in the industry for their ability to withstand corrosive environments and high-pressure applications. End-users rely on suppliers who can demonstrate a proven track history of producing volutes that maintain integrity under stress and variable conditions. Furthermore, serviceability is another dimension where volutes play a significant role. Easy access to replaceable parts within the volute, combined with clear maintenance protocols, can significantly enhance the operational uptime of a pump. Engineers emphasize regular inspection routines to preemptively identify wear or potential blockages within the volute, enhancing system reliability and reducing unexpected downtimes. In summation, the volute of a pump is far more than a structural component; it is a keystone of efficiency, directly contributing to the reliability and effectiveness of pump systems across multiple industries. Its design and material selection embody the essence of engineering precision and innovation. For professionals tasked with selecting or designing pump systems, an understanding of the volute's intricate role and the ability to apply this knowledge is essential to achieving excellence in fluid dynamics and pump technology solutions.

Authoritativeness is underlined by the fact that volute design is guided by internationally recognized standards and certifications. Regulatory bodies and associations such as the Hydraulic Institute set rigorous benchmarks for pump components, including the volute. Professionals certified by these bodies bring a level of authority and trust to their work that reassures end-users about the reliability and efficiency of the pumps they install. Trustworthiness in pump systems hinges on the durability and consistency of the volute's performance over time. The choice of materials for the volute is as critical as its design. Materials such as stainless steel, cast iron, and high-duty alloys are widely trusted in the industry for their ability to withstand corrosive environments and high-pressure applications. End-users rely on suppliers who can demonstrate a proven track history of producing volutes that maintain integrity under stress and variable conditions. Furthermore, serviceability is another dimension where volutes play a significant role. Easy access to replaceable parts within the volute, combined with clear maintenance protocols, can significantly enhance the operational uptime of a pump. Engineers emphasize regular inspection routines to preemptively identify wear or potential blockages within the volute, enhancing system reliability and reducing unexpected downtimes. In summation, the volute of a pump is far more than a structural component; it is a keystone of efficiency, directly contributing to the reliability and effectiveness of pump systems across multiple industries. Its design and material selection embody the essence of engineering precision and innovation. For professionals tasked with selecting or designing pump systems, an understanding of the volute's intricate role and the ability to apply this knowledge is essential to achieving excellence in fluid dynamics and pump technology solutions.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024