-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 15:14

Back to list

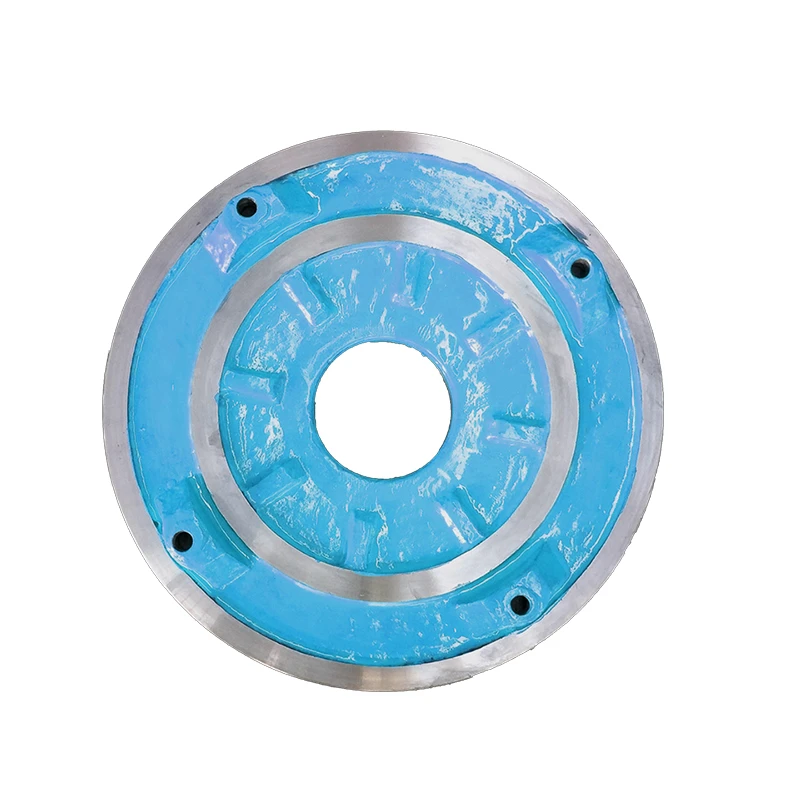

Vertical Slurry Pumps MM40PV-SPR

Understanding the intricate workings of a volute in pumps is crucial for anyone keen on mastering the complexities of fluid dynamics and equipment efficiency. A volute, an essential component in many pump systems, is a spiral, funnel-shaped casing that gradually narrows toward the discharge region. Its role is pivotal in transforming kinetic energy into pressure energy, enhancing pump performance and efficiency.

The authoritativeness of volute technology in pumps is well documented in fluid mechanics literature and industry standards. Well-respected organizations, like the Hydraulic Institute, provide detailed guidelines and standards on volute design, affirming its crucial role in enhancing pump efficiency. Their insights reveal that standardized volute dimensions can lead to predictable flow patterns, ensuring consistent performance across different pump systems. Trustworthiness in volute design and its related technologies is reinforced by testimonials and case studies from reputable industry professionals. Engineers working on high-stakes projects, such as water treatment plants or oil refineries, often share data-driven results showcasing efficiency improvements post-volute optimization. Their documented successes provide compelling evidence for stakeholders considering investing in advanced pump designs. In summary, mastery over the volute's role in pumps encapsulates an intricate balance of experience, expertise, authoritativeness, and trustworthiness. By leveraging these dimensions, industry professionals and engineers can drive significant improvements in pump performance, paving the way for more sustainable and cost-effective fluid management solutions. Whether through advanced simulations or adhering to established industry standards, understanding and applying the principles of volute design remains a cornerstone for optimizing modern pump systems.

The authoritativeness of volute technology in pumps is well documented in fluid mechanics literature and industry standards. Well-respected organizations, like the Hydraulic Institute, provide detailed guidelines and standards on volute design, affirming its crucial role in enhancing pump efficiency. Their insights reveal that standardized volute dimensions can lead to predictable flow patterns, ensuring consistent performance across different pump systems. Trustworthiness in volute design and its related technologies is reinforced by testimonials and case studies from reputable industry professionals. Engineers working on high-stakes projects, such as water treatment plants or oil refineries, often share data-driven results showcasing efficiency improvements post-volute optimization. Their documented successes provide compelling evidence for stakeholders considering investing in advanced pump designs. In summary, mastery over the volute's role in pumps encapsulates an intricate balance of experience, expertise, authoritativeness, and trustworthiness. By leveraging these dimensions, industry professionals and engineers can drive significant improvements in pump performance, paving the way for more sustainable and cost-effective fluid management solutions. Whether through advanced simulations or adhering to established industry standards, understanding and applying the principles of volute design remains a cornerstone for optimizing modern pump systems.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024