-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 01:45

Back to list

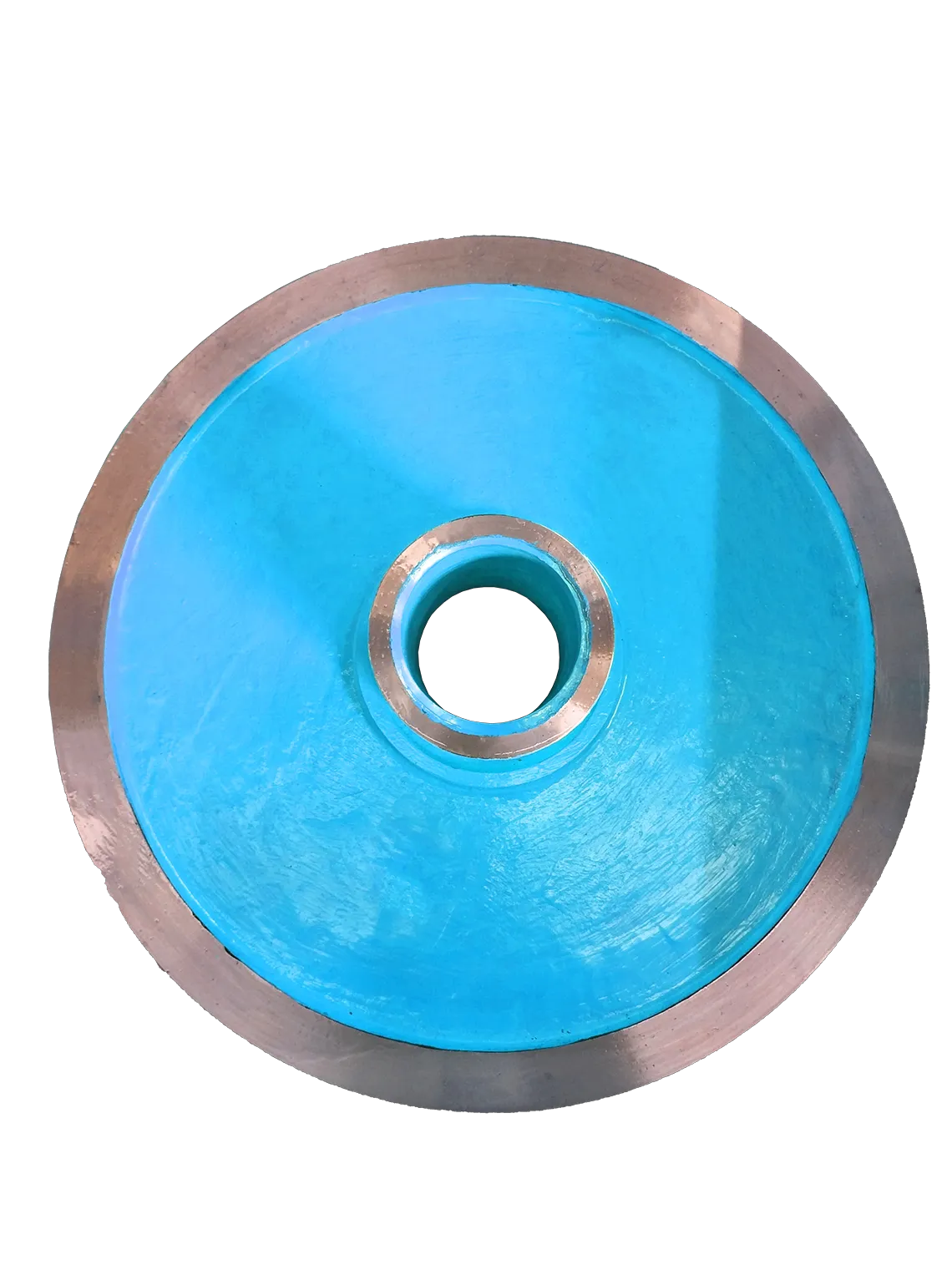

Horizontal Slurry Pumps MM3/2C-AHR

In the realm of centrifugal pumps, the volute plays a pivotal role. As someone deeply entrenched in pump technology, I've witnessed firsthand how the understanding and optimization of a volute can drastically impact pump performance. The volute's unique design is not just a structural component but a critical piece that determines the efficiency and reliability of a centrifugal pump.

Real-world application and testing further validate the authority of a well-designed volute. Engineers conduct rigorous testing under simulated operational conditions to ensure that the volute performs optimally across various scenarios. The data gathered from these tests inform further design refinements and enhancements, contributing to a cycle of continuous improvement. Such detailed testing and quality assurance practices not only reinforce the effectiveness of the volute but also underpin the credibility of the entire pump system. From a user experience standpoint, a pump equipped with a proficiently designed volute offers smoother and quieter operation, vital for industries where noise reduction is a priority. Furthermore, a well-refined volute contributes to the longevity of the pump, as it minimizes stress on the impeller and other components, reducing wear and tear. In conclusion, the volute's role in a centrifugal pump cannot be overstated. Its design influences not only the pump's efficiency and effectiveness but also its reliability and longevity. By leveraging expert engineering practices, adhering to authoritative standards, and focusing on detailed testing, the volute transforms from a simple casing into a cornerstone of centrifugal pump technology. As industries continue to evolve, so too will the advancements in volute design, pushing the boundaries of what centrifugal pumps can achieve. Recognizing and investing in these developments is essential for any sector seeking to maximize pump performance and operational efficiency.

Real-world application and testing further validate the authority of a well-designed volute. Engineers conduct rigorous testing under simulated operational conditions to ensure that the volute performs optimally across various scenarios. The data gathered from these tests inform further design refinements and enhancements, contributing to a cycle of continuous improvement. Such detailed testing and quality assurance practices not only reinforce the effectiveness of the volute but also underpin the credibility of the entire pump system. From a user experience standpoint, a pump equipped with a proficiently designed volute offers smoother and quieter operation, vital for industries where noise reduction is a priority. Furthermore, a well-refined volute contributes to the longevity of the pump, as it minimizes stress on the impeller and other components, reducing wear and tear. In conclusion, the volute's role in a centrifugal pump cannot be overstated. Its design influences not only the pump's efficiency and effectiveness but also its reliability and longevity. By leveraging expert engineering practices, adhering to authoritative standards, and focusing on detailed testing, the volute transforms from a simple casing into a cornerstone of centrifugal pump technology. As industries continue to evolve, so too will the advancements in volute design, pushing the boundaries of what centrifugal pumps can achieve. Recognizing and investing in these developments is essential for any sector seeking to maximize pump performance and operational efficiency.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024