-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 22:17

Back to list

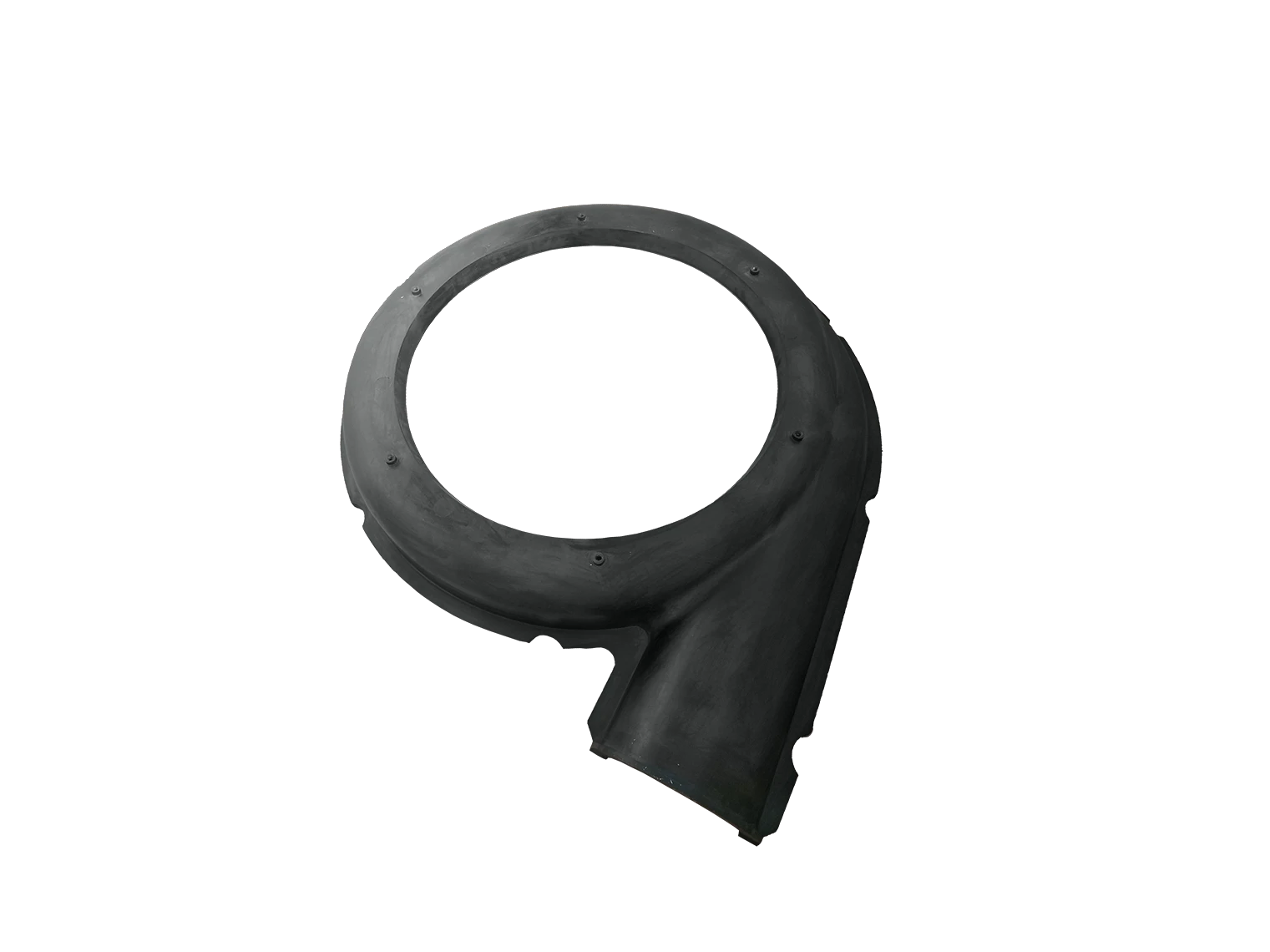

volute casing in centrifugal pump

Efficient centrifugal pump operation is crucial in various industrial applications, with the volute casing playing an integral role in its performance. A well-designed volute casing enhances fluid dynamics, contributing to energy efficiency and reduced operational costs. Through decades of engineering advancements and empirical insights, we explore the intricacies of volute casing design and its significance.

A testament to authoritative insights is evidenced through computational fluid dynamics (CFD) simulations. CFD allows engineers to visualize flow patterns within the volute, fostering an understanding of how modifications impact pump performance. This computational expertise expands the design possibilities, enabling the development of customized solutions tailored to specific operational needs. The empirical data drawn from such simulations is invaluable, providing an authoritative foundation for continued innovations in volute casing design. Complementing technical expertise is the trustworthiness of manufacturers who prioritize the integrity of volute casing production. Manufacturers with a reputation for quality and precision in their volute casings ensure that their products meet rigorous industrial standards. These commitments to quality not only enhance trust among clients but also manifest in reliable, long-lasting pump performance. Keeping abreast of recent advancements, such as the use of advanced materials and manufacturing techniques, further solidifies their authoritative stance in the industry. Moreover, experience shared by industry leaders underlines the importance of routine inspections and maintenance for volute casing longevity. Experienced operators who engage in periodic checks of the casing's structural integrity and performance metrics can preemptively identify potential issues, thereby maintaining optimal flow conditions. This proactive approach is advocated by experts as a best practice, rooted in decades of operational experience. In conclusion, the volute casing in centrifugal pumps is more than a component; it is a pivotal element in maximizing pump efficiency and reliability. Through a synergy of experience, expertise, and continued technological advancement, the volute casing underscores its role in the frontier of fluid engineering. For industries seeking to enhance operational outcomes, an investment in advanced volute casing design represents an investment in sustainable, efficient, and high-performance pumping solutions.

A testament to authoritative insights is evidenced through computational fluid dynamics (CFD) simulations. CFD allows engineers to visualize flow patterns within the volute, fostering an understanding of how modifications impact pump performance. This computational expertise expands the design possibilities, enabling the development of customized solutions tailored to specific operational needs. The empirical data drawn from such simulations is invaluable, providing an authoritative foundation for continued innovations in volute casing design. Complementing technical expertise is the trustworthiness of manufacturers who prioritize the integrity of volute casing production. Manufacturers with a reputation for quality and precision in their volute casings ensure that their products meet rigorous industrial standards. These commitments to quality not only enhance trust among clients but also manifest in reliable, long-lasting pump performance. Keeping abreast of recent advancements, such as the use of advanced materials and manufacturing techniques, further solidifies their authoritative stance in the industry. Moreover, experience shared by industry leaders underlines the importance of routine inspections and maintenance for volute casing longevity. Experienced operators who engage in periodic checks of the casing's structural integrity and performance metrics can preemptively identify potential issues, thereby maintaining optimal flow conditions. This proactive approach is advocated by experts as a best practice, rooted in decades of operational experience. In conclusion, the volute casing in centrifugal pumps is more than a component; it is a pivotal element in maximizing pump efficiency and reliability. Through a synergy of experience, expertise, and continued technological advancement, the volute casing underscores its role in the frontier of fluid engineering. For industries seeking to enhance operational outcomes, an investment in advanced volute casing design represents an investment in sustainable, efficient, and high-performance pumping solutions.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024