-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 05:15

Back to list

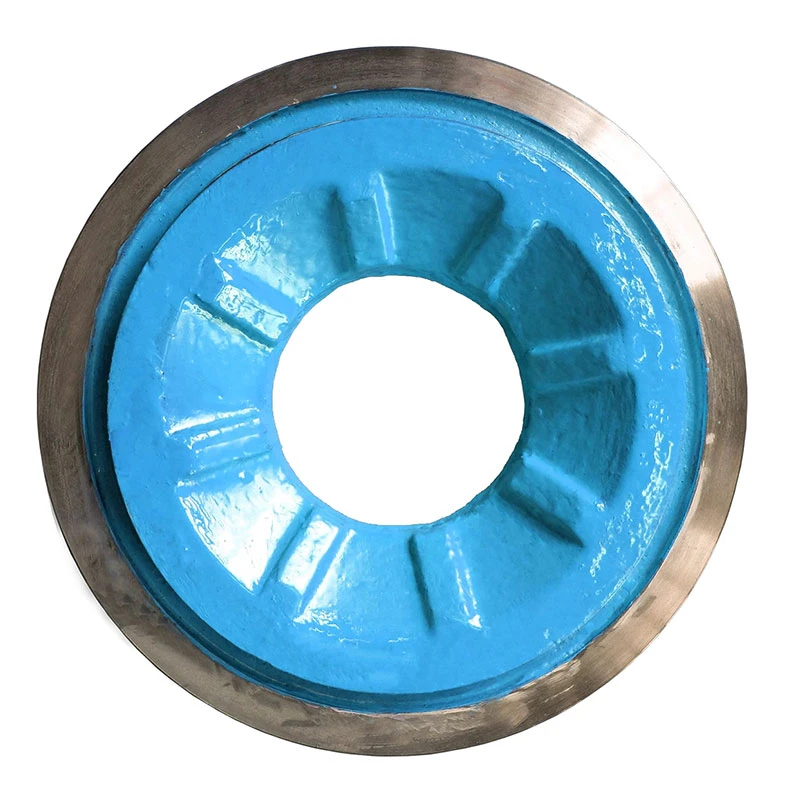

volute casing design

In the intricate world of fluid dynamics, the design of volute casings plays a pivotal role in the efficiency and functionality of centrifugal pumps, which are extensively used in various industrial applications. The essence of an expertly designed volute casing lies in its ability to enhance fluid flow efficiency and minimize energy losses in pumping processes.

Trustworthiness in volute casing design is rooted in adherence to industry standards and best practices. Designers must ensure compliance with international standards such as ISO 5199 for general-purpose industrial pumps and API 610 for centrifugal pumps used in petroleum, petrochemical, and natural gas industries. These standards provide guidelines for dimensions, construction materials, and performance testing, ensuring that the casing design is reliable and robust. A key to developing a volute casing that excels in performance and durability is material selection. Depending on the operational environment, materials must be chosen for their corrosion resistance, strength, and wear properties. For example, stainless steel or cast iron may be selected for applications involving corrosive fluids or high temperatures. The choice of materials not only affects the longevity of the casing but also impacts the overall efficiency of the pump by minimizing maintenance requirements and downtime. Real-world experience highlights the importance of customization in volute casing design. Each application presents unique challenges, and a one-size-fits-all approach often falls short. Collaboration with end-users and feedback from field operations are invaluable in refining casing designs. Implementing design modifications based on operational data can lead to significant improvements in efficiency and reliability, thereby enhancing customer satisfaction and trust in the product. In conclusion, the design of volute casings is a sophisticated science that demands a fine balance between theory and practical application. By emphasizing expertise, authoritative design practices, and building trust through adherence to standards and material excellence, manufacturers can ensure that their volute casings set the benchmark for performance in centrifugal pumps. With ongoing advancements in technology and continuous feedback from the field, the future of volute casing design promises even greater efficiencies and innovations in fluid handling solutions.

Trustworthiness in volute casing design is rooted in adherence to industry standards and best practices. Designers must ensure compliance with international standards such as ISO 5199 for general-purpose industrial pumps and API 610 for centrifugal pumps used in petroleum, petrochemical, and natural gas industries. These standards provide guidelines for dimensions, construction materials, and performance testing, ensuring that the casing design is reliable and robust. A key to developing a volute casing that excels in performance and durability is material selection. Depending on the operational environment, materials must be chosen for their corrosion resistance, strength, and wear properties. For example, stainless steel or cast iron may be selected for applications involving corrosive fluids or high temperatures. The choice of materials not only affects the longevity of the casing but also impacts the overall efficiency of the pump by minimizing maintenance requirements and downtime. Real-world experience highlights the importance of customization in volute casing design. Each application presents unique challenges, and a one-size-fits-all approach often falls short. Collaboration with end-users and feedback from field operations are invaluable in refining casing designs. Implementing design modifications based on operational data can lead to significant improvements in efficiency and reliability, thereby enhancing customer satisfaction and trust in the product. In conclusion, the design of volute casings is a sophisticated science that demands a fine balance between theory and practical application. By emphasizing expertise, authoritative design practices, and building trust through adherence to standards and material excellence, manufacturers can ensure that their volute casings set the benchmark for performance in centrifugal pumps. With ongoing advancements in technology and continuous feedback from the field, the future of volute casing design promises even greater efficiencies and innovations in fluid handling solutions.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024