-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 14:37

Back to list

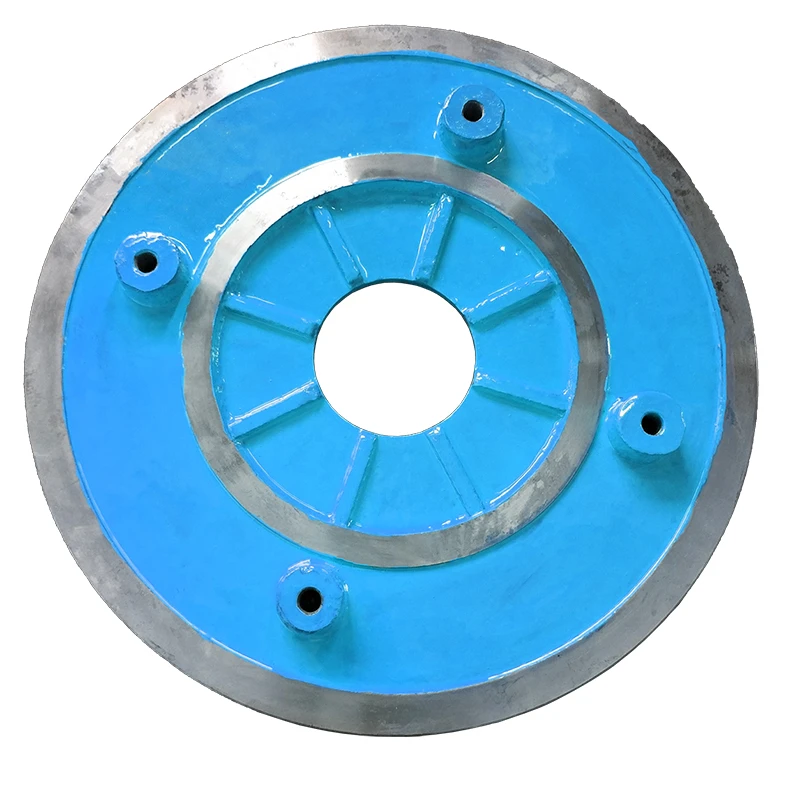

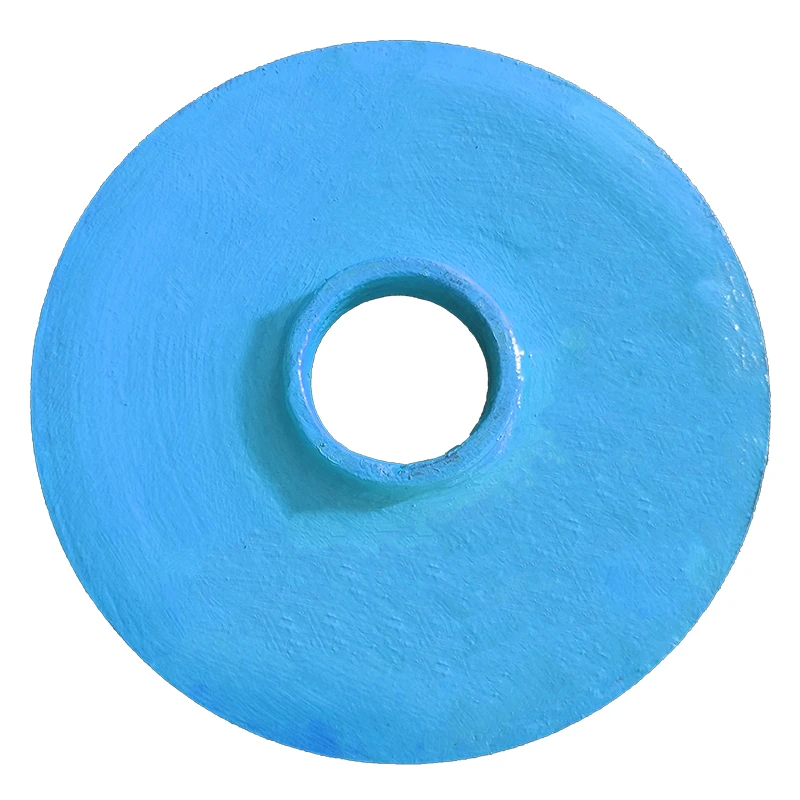

volute casing

Volute casing is a critical component in the realm of fluid dynamics, predominantly found in centrifugal pumps and fans. Their unique design not only enhances the efficiency of fluid handling systems but also elevates the performance of diverse industrial applications. For businesses striving to improve operational efficiency, understanding the nuances of volute casing is paramount.

Trustworthiness in a manufacturer's reputation often correlates with their expertise in volute casing production. Companies that continuously invest in research and development of volute casings typically offer products with superior performance, ease of handling, and compliance with stringent international standards. This dedication to quality often involves leveraging cutting-edge technology and computational fluid dynamics simulations to enhance design and production processes. From an end-user perspective, experience with volute casing-equipped systems often reveals increased energy efficiency and reduced operational costs. Users consistently report noticeable improvements in fluid transfer rates and system stability. This aligns with industry trends emphasizing sustainability and cost-effectiveness — crucial factors for gaining competitive advantage. In conclusion, volute casing serves not merely as a structural component but as a vital element in optimizing pump and fluid handling system performance. In-depth knowledge and expertise in its design and application fundamentally bolster the efficiency and sustainability of industrial processes. By prioritizing quality and innovation, manufacturers and end-users alike cultivate reliability and trustworthiness, amplified by consistent performance and a robust operational foundation. Leveraging the full potential of volute casing through expertise and authority ensures not just immediate success but long-term operational excellence in an ever-evolving industrial landscape.

Trustworthiness in a manufacturer's reputation often correlates with their expertise in volute casing production. Companies that continuously invest in research and development of volute casings typically offer products with superior performance, ease of handling, and compliance with stringent international standards. This dedication to quality often involves leveraging cutting-edge technology and computational fluid dynamics simulations to enhance design and production processes. From an end-user perspective, experience with volute casing-equipped systems often reveals increased energy efficiency and reduced operational costs. Users consistently report noticeable improvements in fluid transfer rates and system stability. This aligns with industry trends emphasizing sustainability and cost-effectiveness — crucial factors for gaining competitive advantage. In conclusion, volute casing serves not merely as a structural component but as a vital element in optimizing pump and fluid handling system performance. In-depth knowledge and expertise in its design and application fundamentally bolster the efficiency and sustainability of industrial processes. By prioritizing quality and innovation, manufacturers and end-users alike cultivate reliability and trustworthiness, amplified by consistent performance and a robust operational foundation. Leveraging the full potential of volute casing through expertise and authority ensures not just immediate success but long-term operational excellence in an ever-evolving industrial landscape.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024