-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 09:19

Back to list

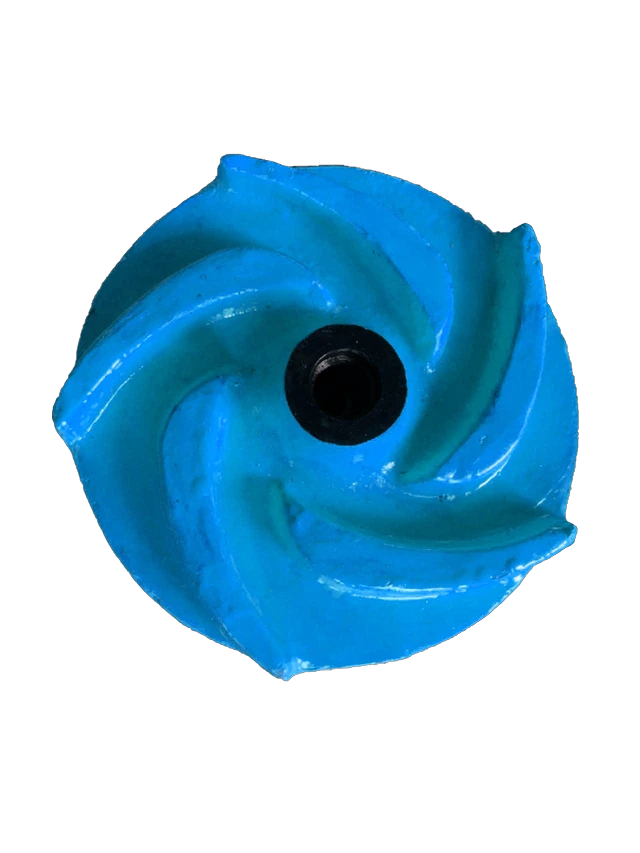

vertical turbine pump impeller

Understanding the intricate details of a vertical turbine pump impeller can transform the performance and efficiency of your fluid-handling systems. Known for their elegance in design and robustness in application, these impellers are pivotal in industries ranging from municipal water services to petrochemical processing and beyond.

Application Versatility The versatility of vertical turbine pump impellers is evident in their wide range of applications. They are used extensively in water supply systems, where they efficiently pump groundwater into distribution networks for residential consumption. In the industrial sector, these impellers are quintessential for cooling processes, irrigation, and even in firefighting systems due to their ability to operate efficiently at varying pressures and flow rates. Additionally, the versatility extends to the petrochemical industry, where they handle a variety of hydrocarbon products with ease. Their capacity to be tailored for performance with different head and flow requirements makes them indispensable in these energy-intensive applications. Authority and Trustworthiness in the Industry The development and continuous improvement of vertical turbine pump impellers have relied on decades of research and field testing. Leading manufacturers regularly collaborate with research institutions and leverage field data to refine impeller designs and materials. This collaboration ensures the impellers not only meet but exceed industry standards for efficiency, durability, and reliability. Certified installation and maintenance services further enhance the trustworthiness of these pumps. Professional services ensure that each component, including the impeller, is installed and maintained according to stringent industry standards, providing assurance of optimal performance over the long term. Conclusion The vertical turbine pump impeller stands as a testament to engineering excellence, combining subtle design intricacies with robust material usage to meet demanding application needs. Its evolution is reflective of technological advancements and an enduring commitment to efficiency and sustainability. By understanding and investing in the right impeller design and materials, businesses can significantly enhance their fluid management systems' operational efficiency and reliability, ensuring a sound return on investment and a reduced environmental footprint.

Application Versatility The versatility of vertical turbine pump impellers is evident in their wide range of applications. They are used extensively in water supply systems, where they efficiently pump groundwater into distribution networks for residential consumption. In the industrial sector, these impellers are quintessential for cooling processes, irrigation, and even in firefighting systems due to their ability to operate efficiently at varying pressures and flow rates. Additionally, the versatility extends to the petrochemical industry, where they handle a variety of hydrocarbon products with ease. Their capacity to be tailored for performance with different head and flow requirements makes them indispensable in these energy-intensive applications. Authority and Trustworthiness in the Industry The development and continuous improvement of vertical turbine pump impellers have relied on decades of research and field testing. Leading manufacturers regularly collaborate with research institutions and leverage field data to refine impeller designs and materials. This collaboration ensures the impellers not only meet but exceed industry standards for efficiency, durability, and reliability. Certified installation and maintenance services further enhance the trustworthiness of these pumps. Professional services ensure that each component, including the impeller, is installed and maintained according to stringent industry standards, providing assurance of optimal performance over the long term. Conclusion The vertical turbine pump impeller stands as a testament to engineering excellence, combining subtle design intricacies with robust material usage to meet demanding application needs. Its evolution is reflective of technological advancements and an enduring commitment to efficiency and sustainability. By understanding and investing in the right impeller design and materials, businesses can significantly enhance their fluid management systems' operational efficiency and reliability, ensuring a sound return on investment and a reduced environmental footprint.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024