-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 01, 2025 05:15

Back to list

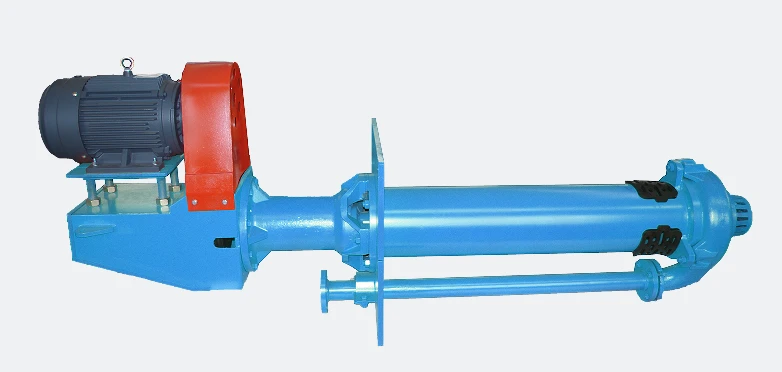

vertical slurry sump pumps

In industries where handling abrasive and corrosive slurries is part of everyday operations, the right equipment can mean the difference between seamless productivity and operational downtime. Vertical slurry sump pumps play a pivotal role in these environments, offering unique advantages over traditional horizontal pumps. Understanding their functionality, benefits, and applications can guide industries in optimizing their processes and improving efficiency.

In wastewater treatment plants, vertical slurry sump pumps deal with sludge and other semi-solid materials. Their robust design ensures that they can handle the fibrous and gritty nature of waste materials without frequent clogging. Chemical plants benefit from these pumps due to their ability to handle corrosive slurries, maintaining the integrity of chemical processes that require precise and uninterrupted material flow. Trust in vertical slurry sump pumps is bolstered by their proven reliability and the endorsement of industry experts who recognize their role in optimizing flow management systems. Operators appreciate the pumps' ability to perform consistently under challenging conditions, reducing operating costs and enhancing system dependability. Manufacturers offer comprehensive support, providing operators with guidance on optimal pump selection and application, maintenance practices, and troubleshooting techniques. This holistic support underscores the pumps’ credibility as an integral component in industrial fluid management. For businesses investing in vertical slurry sump pumps, it is essential to consider factors such as the nature of the slurry, pump sizing, and performance requirements. Consulting with professionals who have extensive expertise in slurry pumping solutions can ensure the selection of a pump that aligns with specific operational needs, maximizing performance output while minimizing wear and tear. In conclusion, vertical slurry sump pumps stand out as an innovation in fluid management technology, catering to the needs of industrial sectors that deal with the challenges of slurry transportation. Their specialized design and robust construction, coupled with their efficient handling capabilities, position them as an authoritative choice for industries looking to maintain optimal productivity and reliability. Leveraging the experience and expertise offered by seasoned professionals and manufacturers, businesses can confidently integrate these pumps into their operations, underscoring their investment in quality and efficiency.

In wastewater treatment plants, vertical slurry sump pumps deal with sludge and other semi-solid materials. Their robust design ensures that they can handle the fibrous and gritty nature of waste materials without frequent clogging. Chemical plants benefit from these pumps due to their ability to handle corrosive slurries, maintaining the integrity of chemical processes that require precise and uninterrupted material flow. Trust in vertical slurry sump pumps is bolstered by their proven reliability and the endorsement of industry experts who recognize their role in optimizing flow management systems. Operators appreciate the pumps' ability to perform consistently under challenging conditions, reducing operating costs and enhancing system dependability. Manufacturers offer comprehensive support, providing operators with guidance on optimal pump selection and application, maintenance practices, and troubleshooting techniques. This holistic support underscores the pumps’ credibility as an integral component in industrial fluid management. For businesses investing in vertical slurry sump pumps, it is essential to consider factors such as the nature of the slurry, pump sizing, and performance requirements. Consulting with professionals who have extensive expertise in slurry pumping solutions can ensure the selection of a pump that aligns with specific operational needs, maximizing performance output while minimizing wear and tear. In conclusion, vertical slurry sump pumps stand out as an innovation in fluid management technology, catering to the needs of industrial sectors that deal with the challenges of slurry transportation. Their specialized design and robust construction, coupled with their efficient handling capabilities, position them as an authoritative choice for industries looking to maintain optimal productivity and reliability. Leveraging the experience and expertise offered by seasoned professionals and manufacturers, businesses can confidently integrate these pumps into their operations, underscoring their investment in quality and efficiency.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024