-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 12:20

Back to list

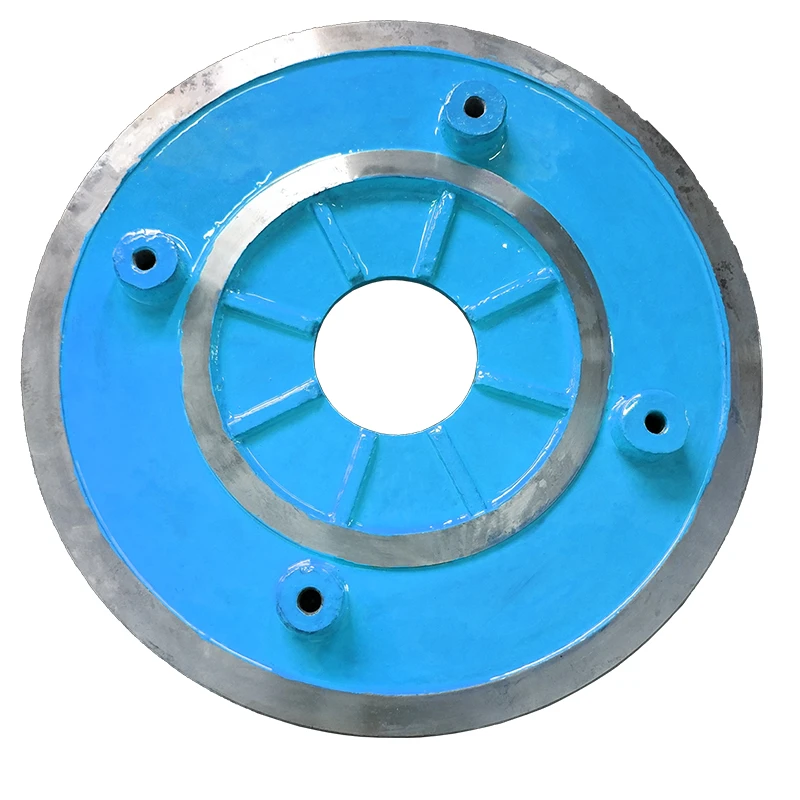

vertical shaft bearing assembly

Vertical shaft bearing assemblies are crucial components in various industrial applications, ranging from wind turbines to submersible pumps. Their role is to support the rotating shaft and handle both radial and axial loads. Understanding the intricacies of these assemblies is essential for selecting the right product for a specific application, ensuring optimal performance and longevity.

Vertical shaft bearing assemblies vary significantly between industries. In wind turbine applications, they must endure variable loads and harsh weather, necessitating robust designs with high load capacities. In contrast, in pump assemblies, bearings often handle less demanding conditions but require excellent water resistance. Innovations in bearing technology are continuously improving the performance of vertical shaft assemblies. Advanced materials, such as hybrid bearings combining steel and ceramic, offer a balance of strength and resistance to environmental factors. Additionally, smart bearings equipped with sensors can monitor parameters like temperature and vibration in real-time, providing valuable data for predictive maintenance. Manufacturers play an authoritative role in the bearing industry by adhering to stringent quality standards and offering expert guidance to their clients. They invest heavily in research and development, ensuring their products meet the evolving demands of modern machinery. Choosing a reputable supplier provides assurance of compliance with industry standards and access to technical support. In conclusion, selecting the optimal vertical shaft bearing assembly involves a thorough understanding of the specific application requirements, operating conditions, and maintenance practices. Leveraging the expertise of manufacturers and staying informed about technological advancements can enhance performance, extend service life, and reduce operational costs, making it a crucial factor in industrial success.

Vertical shaft bearing assemblies vary significantly between industries. In wind turbine applications, they must endure variable loads and harsh weather, necessitating robust designs with high load capacities. In contrast, in pump assemblies, bearings often handle less demanding conditions but require excellent water resistance. Innovations in bearing technology are continuously improving the performance of vertical shaft assemblies. Advanced materials, such as hybrid bearings combining steel and ceramic, offer a balance of strength and resistance to environmental factors. Additionally, smart bearings equipped with sensors can monitor parameters like temperature and vibration in real-time, providing valuable data for predictive maintenance. Manufacturers play an authoritative role in the bearing industry by adhering to stringent quality standards and offering expert guidance to their clients. They invest heavily in research and development, ensuring their products meet the evolving demands of modern machinery. Choosing a reputable supplier provides assurance of compliance with industry standards and access to technical support. In conclusion, selecting the optimal vertical shaft bearing assembly involves a thorough understanding of the specific application requirements, operating conditions, and maintenance practices. Leveraging the expertise of manufacturers and staying informed about technological advancements can enhance performance, extend service life, and reduce operational costs, making it a crucial factor in industrial success.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024