-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

vertical impeller pump

Understanding Vertical Impeller Pumps A Comprehensive Overview

Vertical impeller pumps, also known as vertical turbine pumps, are specialized hydraulic machines predominantly used for lifting water from deep sources to the surface. These pumps are essential in various industries, including agriculture, water supply and distribution, and industrial applications. This article delves into the structure, functioning, advantages, and applications of vertical impeller pumps.

Structure and Components

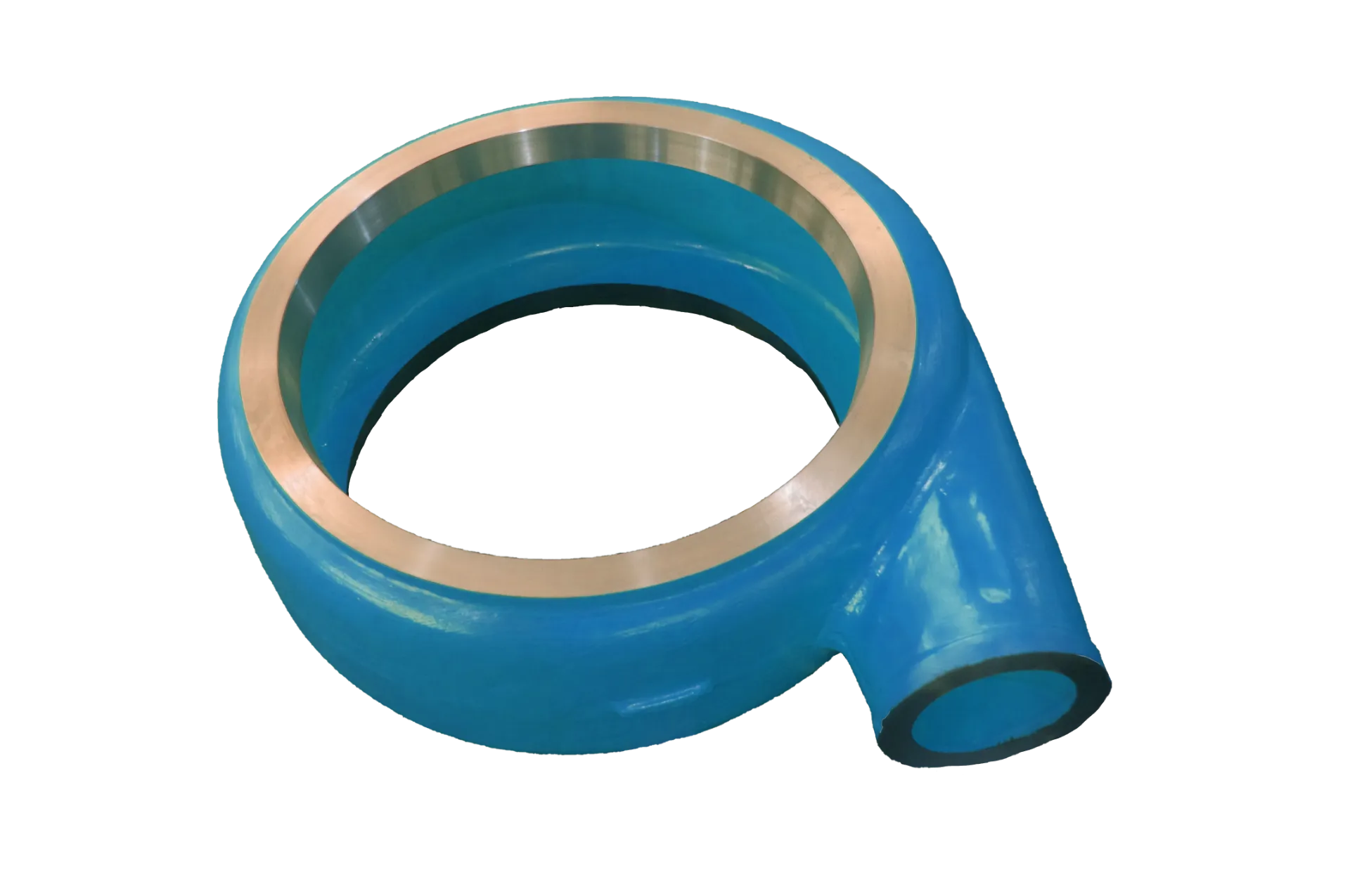

A vertical impeller pump primarily consists of a motor, a vertical shaft, an impeller, a bowl assembly, and a pump casing. At the top, the motor drives the vertical shaft, which extends below the surface into the water source. The impeller, located at the end of the shaft, is designed with blades that rotate to create a centrifugal force, drawing water into the pump and pushing it upwards.

The bowl assembly houses multiple stages of impellers and diffusers

. Each stage works to increase the pressure of the water as it ascends, making vertical impeller pumps particularly effective for high-lift applications. The casing ensures that the water being pumped does not escape and provides a streamlined path for the water to flow towards its desired destination.Working Principle

Vertical impeller pumps operate on the principle of centrifugal force. When the motor activates the vertical shaft, the impeller begins to spin. The rotation of the impeller blades accelerates the water being drawn into the pump. As the water enters the impeller, its velocity increases, which is further enhanced as it passes through the diffuser. The diffuser converts this kinetic energy into pressure energy, allowing the water to surge upward through the discharge pipe.

This process can be repeated through multiple stages, continually increasing the pressure and lifting the water over considerable heights, making vertical impeller pumps extremely efficient in a wide variety of applications.

vertical impeller pump

Advantages

One of the primary advantages of vertical impeller pumps is their ability to handle high flow rates while effectively lifting water from substantial depths. Their vertical design saves space, making them ideal for installations where horizontal configuration might be impractical. Additionally, these pumps are typically more efficient than horizontal pumps for deep-well applications, as they reduce friction losses and maintain performance over longer distances.

Another advantage is their versatility. Vertical impeller pumps can be customized with different impeller designs to accommodate various fluid types, including clean water, sewage, and other viscous fluids. Furthermore, they can operate in extreme conditions, including high temperatures and varying pressure ranges, making them suitable for diverse industrial applications.

Applications

Vertical impeller pumps serve numerous applications across different sectors. In agriculture, they are commonly used for irrigation purposes, helping to transport water from deep wells to fields. In municipal water systems, these pumps play a crucial role in supplying clean water to communities by lifting groundwater from aquifers.

In industrial settings, vertical impeller pumps are utilized in processes requiring the transfer of fluids across significant heights, such as cooling water systems, chemical processing, and wastewater management. Their ability to efficiently manage large volumes of water makes them indispensable in such scenarios.

Conclusion

Vertical impeller pumps are vital components in various industries, providing an efficient and effective means of lifting water from deep sources. With their unique design and operational advantages, they continue to play a crucial role in modern infrastructure, contributing to agricultural productivity and industrial efficiency. Understanding their function and applications can help industries make informed decisions for their water management systems.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024