-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 01, 2025 01:18

Back to list

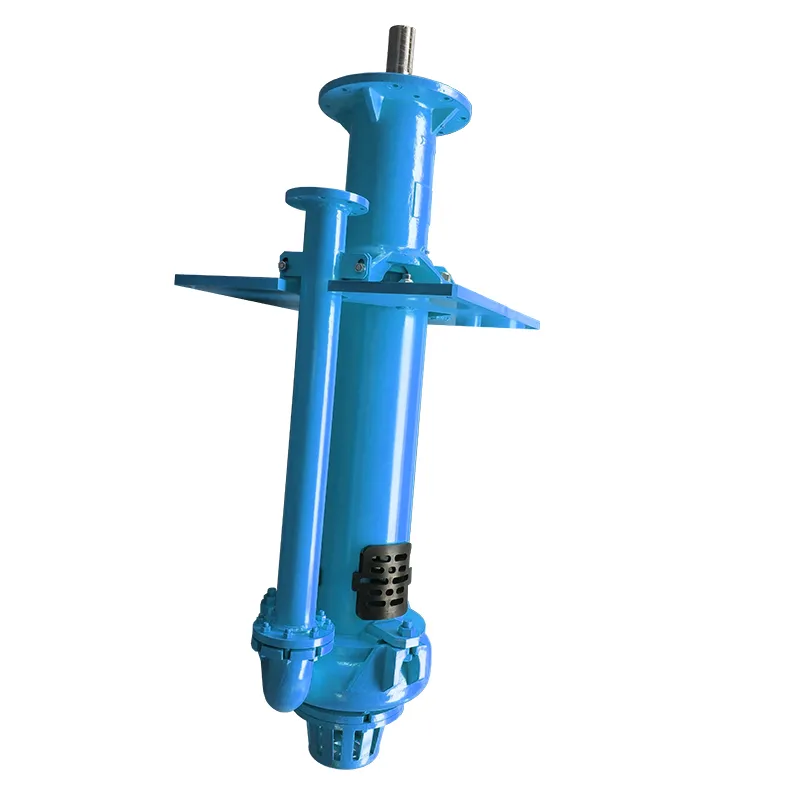

vertical end suction centrifugal pump

In the landscape of industrial and commercial fluid management, the vertical end suction centrifugal pump stands out as a critical component of efficient and reliable operations. Industry professionals and engineers continually seek pumping solutions that not only meet specific performance criteria but also ensure long-term durability and ease of maintenance. Understanding the nuances of these pumps enhances their value proposition in various applications such as HVAC systems, water treatment plants, and industrial processing units.

From an expertise perspective, selecting a vertical end suction centrifugal pump requires a thorough understanding of the application's specific needs. Flow rate, head height, fluid characteristics, and ambient operational conditions must be meticulously evaluated. Consulting with experts ensures that the pump’s specifications align perfectly with operational demands, preventing issues such as cavitation, which can significantly impair performance and lead to premature wear and failure. Verifying the manufacturer's credentials is another critical step. Industry leaders in pump manufacturing often have decades of experience and are known for stringent quality control measures. This assurance of quality extends to post-purchase support, where authorized service centers and comprehensive warranties provide peace of mind. Reading and analyzing case studies or real-world success stories can also enhance the credibility of a pump and its manufacturer, instilling confidence in the decision-making process. On the technological frontier, advancements in pump design and monitoring have added another layer of sophistication to the operational management of vertical end suction centrifugal pumps. Integrated sensors and IoT capabilities enable real-time performance tracking and predictive maintenance, effectively pre-empting potential issues before they escalate into major problems. This not only enhances operational efficiency but also aligns with modern industry 4.0 paradigms, driving smarter facility management. The trustworthiness of vertical end suction centrifugal pumps can also be reinforced through compatibility with various industry standards and certifications. Ensuring that pumps comply with regulatory requirements and guidelines such as those from ISO or ANSI not only underscores the product’s quality but also simplifies integration into existing systems that must adhere to these standards. In conclusion, the vertical end suction centrifugal pump is an unparalleled asset in fluid dynamics, balancing efficiency, and reliability with ease of maintenance and technological innovation. Proper selection, informed by expert advice and supported by authoritative manufacturing standards, ensures that these pumps deliver optimal performance in diverse and challenging environments. Consequently, they remain a top choice for engineers and facility managers seeking uncompromising quality and operational excellence.

From an expertise perspective, selecting a vertical end suction centrifugal pump requires a thorough understanding of the application's specific needs. Flow rate, head height, fluid characteristics, and ambient operational conditions must be meticulously evaluated. Consulting with experts ensures that the pump’s specifications align perfectly with operational demands, preventing issues such as cavitation, which can significantly impair performance and lead to premature wear and failure. Verifying the manufacturer's credentials is another critical step. Industry leaders in pump manufacturing often have decades of experience and are known for stringent quality control measures. This assurance of quality extends to post-purchase support, where authorized service centers and comprehensive warranties provide peace of mind. Reading and analyzing case studies or real-world success stories can also enhance the credibility of a pump and its manufacturer, instilling confidence in the decision-making process. On the technological frontier, advancements in pump design and monitoring have added another layer of sophistication to the operational management of vertical end suction centrifugal pumps. Integrated sensors and IoT capabilities enable real-time performance tracking and predictive maintenance, effectively pre-empting potential issues before they escalate into major problems. This not only enhances operational efficiency but also aligns with modern industry 4.0 paradigms, driving smarter facility management. The trustworthiness of vertical end suction centrifugal pumps can also be reinforced through compatibility with various industry standards and certifications. Ensuring that pumps comply with regulatory requirements and guidelines such as those from ISO or ANSI not only underscores the product’s quality but also simplifies integration into existing systems that must adhere to these standards. In conclusion, the vertical end suction centrifugal pump is an unparalleled asset in fluid dynamics, balancing efficiency, and reliability with ease of maintenance and technological innovation. Proper selection, informed by expert advice and supported by authoritative manufacturing standards, ensures that these pumps deliver optimal performance in diverse and challenging environments. Consequently, they remain a top choice for engineers and facility managers seeking uncompromising quality and operational excellence.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024